Method for preparing nanometer lithium iron phosphate/carbon compound with stable low temperature performance

A technology of lithium iron phosphate and low-temperature performance, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of difficulty in forming uniform carbon coating, and achieve easy control of preparation conditions, The equipment and process are simple, and the effect of improving low-temperature electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

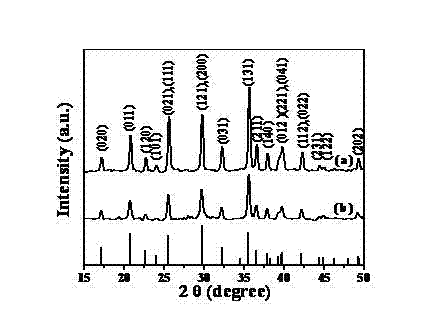

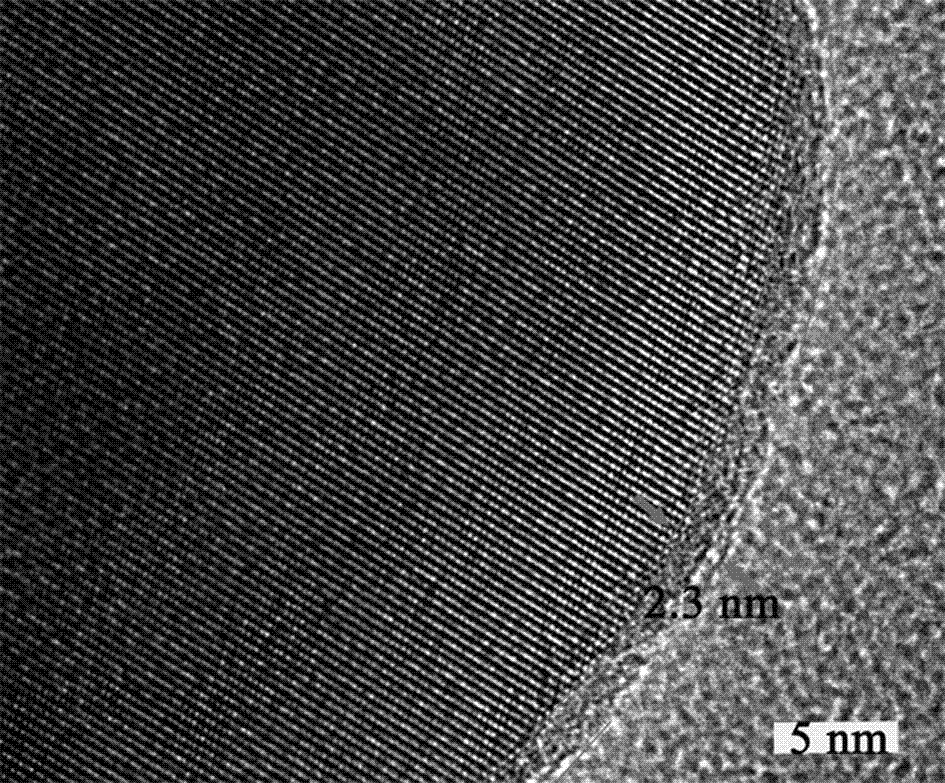

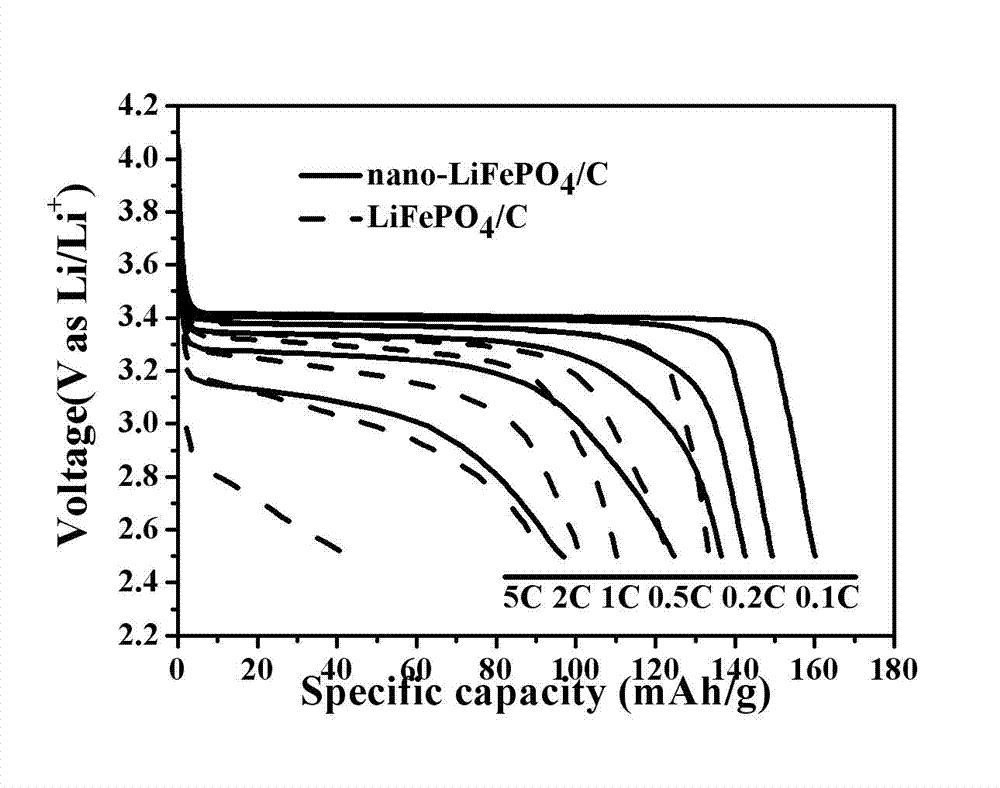

[0025] Ferrous oxalate and lithium dihydrogen phosphate are directly mixed in the ball mill tank according to the Fe:Li:P molar ratio of 1:1:l, and 0.05 g of citric acid and 60% PVP (equivalent to the mass percentage of lithium iron phosphate) are added ), ball milled in an appropriate amount of absolute ethanol at 450 rpm / min for 20 hours, heated up in a nitrogen atmosphere after drying at a rate of 3°C / min, stayed at 350°C for 3 hours, stayed at 700°C for 8 hours, and then naturally cooling, and finally obtained nano-sized LiFePO with uniform carbon coating 4 / C complex. The particle size is 80 nm, and the discharge capacity at room temperature at 0.1 C rate can reach 160 mAh / g, at -20°C at 0.1 C rate, the discharge capacity can reach 126 mAh / g, at -20°C at 0.6C rate After 500 cycles, the discharge capacity remains above 97% of the initial capacity.

[0026] In order to reflect the role of composite carbon sources, LiFePO with a single carbon source was prepared at the same...

Embodiment 2

[0028] Ferrous oxalate, lithium carbonate, and ammonium dihydrogen phosphate are directly mixed in the ball mill tank according to the Fe:Li:P molar ratio of 1:1:l, and 0.5 g of citric acid and 10% PVP (equivalent to lithium iron phosphate mass percent), ball milled in an appropriate amount of absolute ethanol at 400 rpm / min for 15 hours, and after drying, heated up in a nitrogen atmosphere at a heating rate of 3°C / min, staying at 350°C for 3 hours, and staying at 700°C for 8 hours , followed by natural cooling, and finally obtained nano-sized LiFePO with uniform carbon coating 4 / C complex. The particle size is 140 nm, and the discharge capacity at 0.1 C rate at room temperature can reach 144 mAh / g, and the discharge capacity at 0.1 C rate at -20 °C can reach 130 mAh / g.

Embodiment 3

[0030] Ferrous oxalate, lithium carbonate, and ammonium dihydrogen phosphate are directly mixed in the ball mill tank according to the Fe:Li:P molar ratio of 1:1:l, and 0.5 g of citric acid and 30% of PVP (equivalent to lithium iron phosphate mass percent), ball milled in an appropriate amount of absolute ethanol at 400 rpm / min for 10 hours, and after drying, heated up in a nitrogen atmosphere at a heating rate of 3°C / min, stayed at 350°C for 3 hours, and stayed at 700°C for 8 hours , followed by natural cooling, and finally obtained nano-sized LiFePO with uniform carbon coating 4 / C complex. The size of the particles is 120 nm, and the discharge capacity at 0.1 C rate at room temperature can reach 131 mAh / g, and the discharge capacity at 0.1 C rate at -20 °C can reach 115 mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com