Copper-based catalyst and preparation method and application thereof

A technology of copper-based catalysts and solvents, which is applied in the field of copper-based catalysts, preparation and application, can solve the problems of easy pulverization of catalysts, complicated preparation process, and low catalytic activity, and achieve improved catalytic activity, good preparation repeatability, increased The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

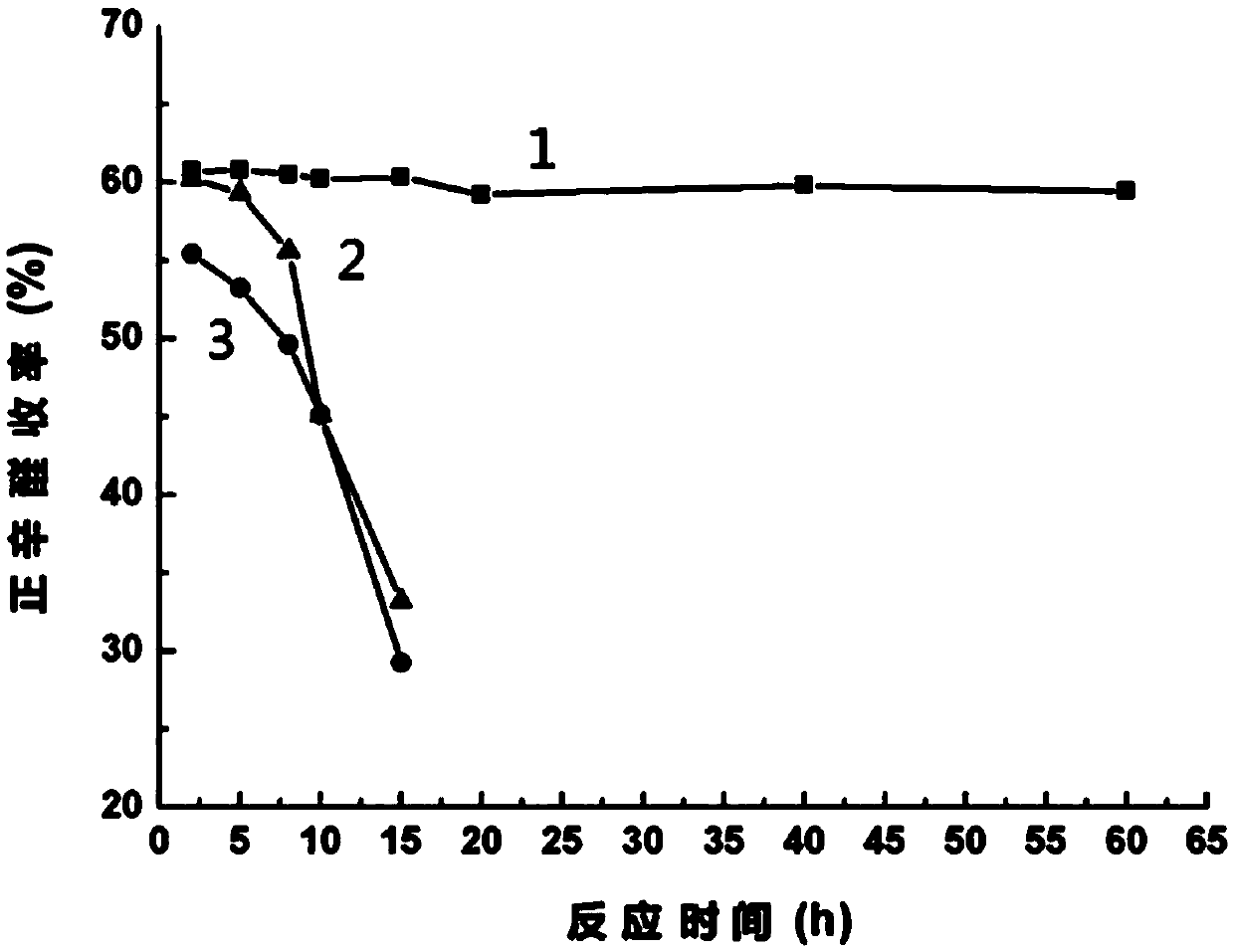

Embodiment 1

[0044] Weigh 72gCu(NO 3 ) 2 ·3H 2 O, 178.5gZn(NO 3 ) 2 ·6H 2 O and 37.5gAl(NO 3 ) 3 9H 2 O is dissolved in deionized water to form a mixed solution with a molar concentration of 1mol / L, in which Cu 2+ : Zn 2+ :Al 3+ The molar ratio is 3:6:1; Weigh 115g of ammonium carbonate and dissolve it in 1L of deionized water to make a 1.2mol / L aqueous solution. The two solutions were fed and reacted in parallel at 80° C., and the pH value of the reaction was controlled to be about 8.0. Continue to stir for 12 hours after the feed is complete, age for 10 hours, filter the precipitate, wash with deionized water, dry at 80°C for 12 hours, and then heat up to 500°C in a muffle furnace for 5 hours at a rate of 3°C / min. . Finally, 2% graphite of the total mass of the obtained substance was added, and the catalyst sample A was obtained by tableting in a tablet press.

Embodiment 2

[0046] Weigh 108.7gCu(NO 3 ) 2 ·3H 2 O, 134gZn(NO 3 ) 2 ·6H 2 O, and 37.5gAl(NO 3 ) 3 9H 2 O is dissolved in deionized water to form a mixed solution with a molar concentration of 1mol / L, in which Cu 2+ : Zn 2+ :Al 3+ The molar ratio is 4.5:4.5:1; Weigh 115g of ammonium carbonate and dissolve it in 1L of deionized water to make a 1.2mol / L aqueous solution. The two solutions were fed and reacted in parallel at 80° C., and the pH value of the reaction was controlled to be about 8.0. Continue to stir for 12 hours after feeding, age for 6 hours, filter the precipitate, wash with deionized water, dry at 80°C for 12 hours, and then heat up to 500°C in a muffle furnace for 5 hours at a rate of 3°C / min. . Finally, 2% graphite of the total mass of the obtained substance was added, and the catalyst sample B was obtained by tableting in a tablet press.

Embodiment 3

[0048] Weigh 48gCu(NO 3 ) 2 ·3H 2 O, 208gZn(NO 3 ) 2 ·6H 2 O, and 37.5gAl(NO 3 ) 3 9H 2 O is dissolved in deionized water to form a mixed solution with a molar concentration of 1mol / L, in which Cu 2+ : Zn 2+ :Al 3+ The molar ratio is 2:7:1; Weigh 115g of ammonium carbonate and dissolve it in 1L of deionized water to make a 1.2mol / L aqueous solution. The two solutions were fed and reacted in parallel at 80° C., and the pH value of the reaction was controlled to be about 8.0. Continue to stir for 12 hours after the feed is complete, age for 12 hours, filter the precipitate, wash with deionized water, dry at 80°C for 12 hours, and then heat up to 500°C in a muffle furnace for 5 hours at a rate of 2°C / min. . Finally, 2% graphite was added to the total mass of the obtained substance, and the catalyst sample C was obtained by tableting in a tablet press.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com