Preparation method of single-crystal nickel-cobalt-manganese ternary positive electrode material

A cathode material and ternary material technology, which is applied in the field of preparation of single crystal nickel-cobalt-manganese ternary cathode materials, can solve the problems of poor rate performance, poor cycle stability, and high cost of low-cobalt ternary cathode materials, and achieve stable cycle Excellent stability and rate performance, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

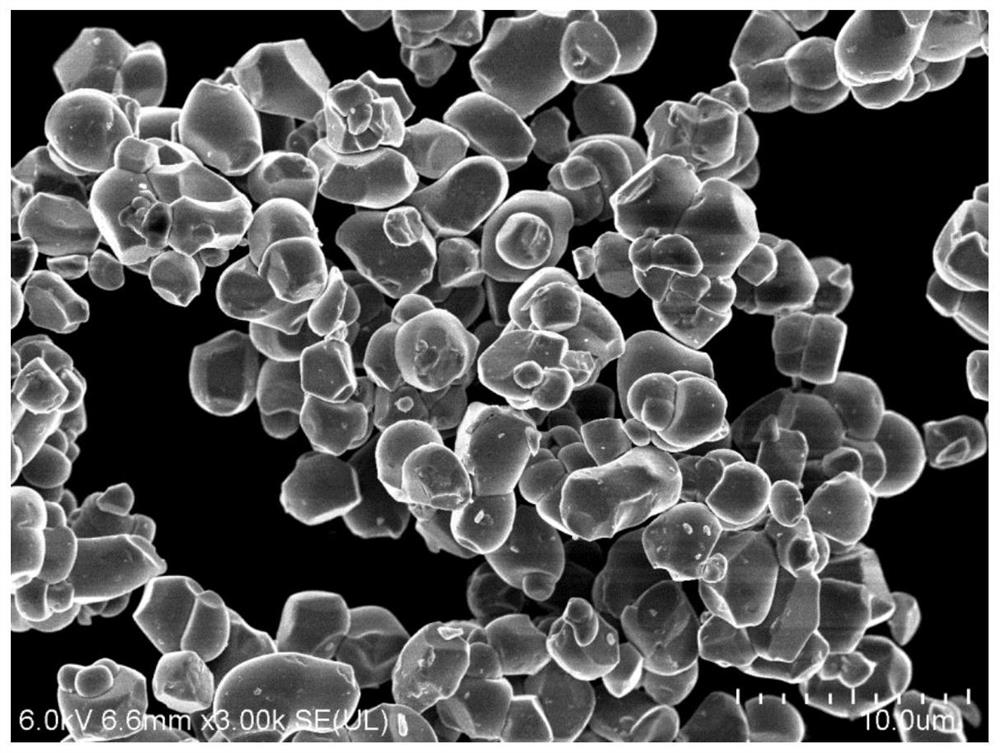

[0045] This embodiment provides a preparation method of a single crystal nickel-cobalt-manganese ternary positive electrode material. It is prepared by the following preparation method.

[0046] 1) Put Ni 0.65 Co 0.07 Mn 0.28 (OH) 2 300g of precursor, 127.6g of lithium carbonate, 0.41g of strontium carbonate, 0.82g of nano-zirconia, 0.77g of nano-yttrium oxide; 3g of additive HPMC (hydroxypropyl methylcellulose) was added, and 20g of deionized water was sprayed evenly, The mixing and granulating machine is used for mixing and granulating. The cylinder of the mixing and granulating machine used is a straight cylinder. The stirring paddle and the reamer are installed on the same shaft, and the materials can be mixed and granulated in a short time. . There is a transmission shaft in the center of the bottom of the cylinder body, a horizontal stirring paddle at the top of the lowermost part, and a vertical scraper at the top of the cross section of the stirring paddle. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com