Near-infrared fluorescent powder, preparation method and LED device formed by near-infrared fluorescent powder

A near-infrared and phosphor technology, used in semiconductor devices, chemical instruments and methods, luminescent materials, etc., can solve the problems of high cost of near-infrared light sources, discontinuous emission bands, and narrow emission ranges, and achieve physical and chemical stability. Good, low cost of raw materials, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

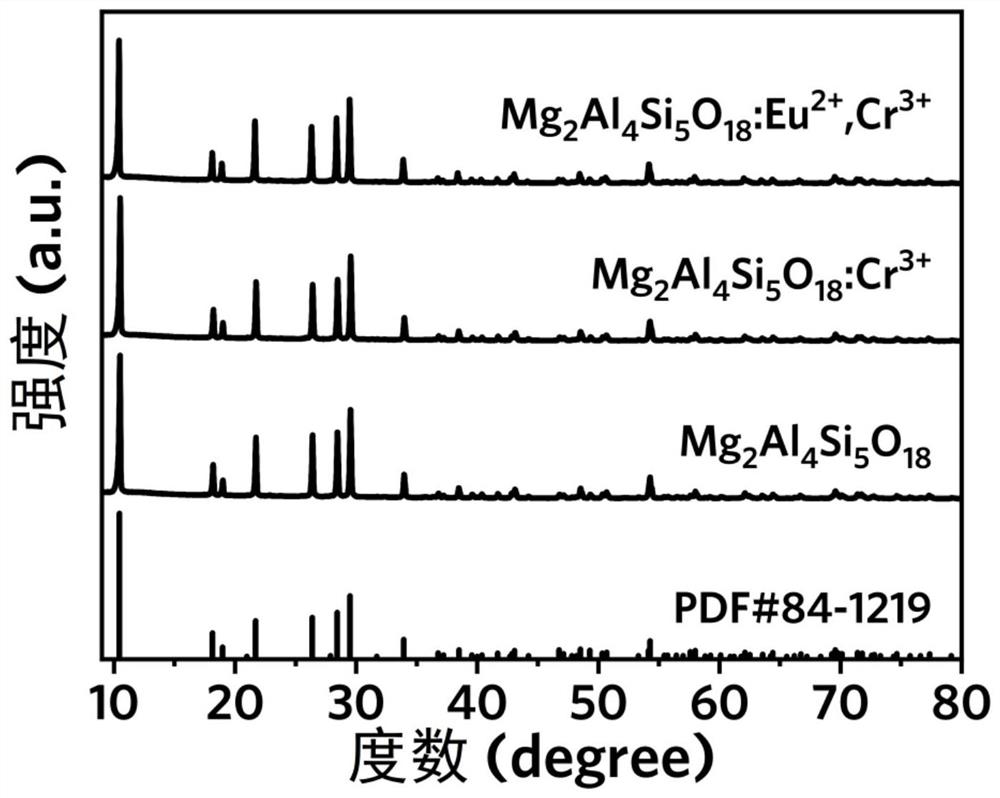

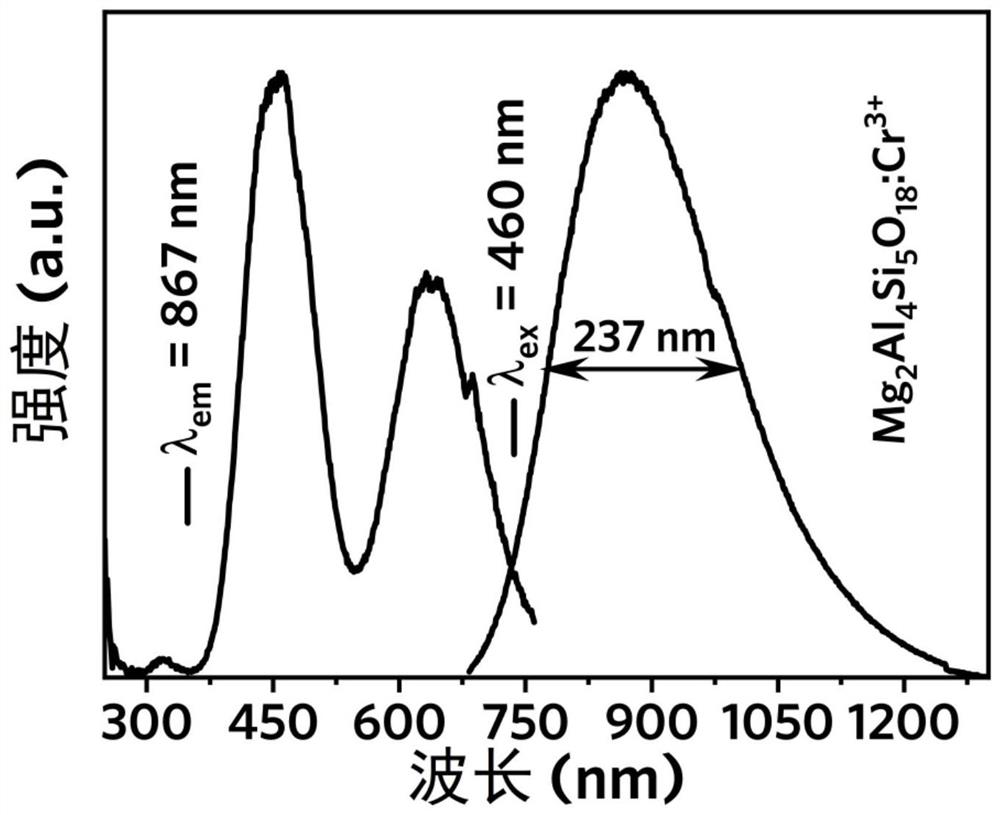

[0051] MgO, Al 2 O 3 , SiO 2 and Cr 2 O 3 The powder is weighed according to the formula of the molar ratio of Mg, Al, Si and Cr elements of 30:19:50:1, and then ground with an agate mortar for 0.5–1 h until the mixture is uniform. Put the alumina crucible containing the mixed and ground glass matrix raw materials into the 5% H 2 and 95%N 2 In a tube furnace with a reducing atmosphere, the temperature was kept at 1550 °C for 5 hours; the obtained melt was naturally cooled with the tube furnace to obtain a blue glass matrix, that is, a blue glass precursor, and then the blue glass matrix was put into a 5% H 2 and 95%N 2 In a tube furnace in a reducing atmosphere, the temperature is kept at 1050° C. for 1 hour to obtain near-infrared fluorescent glass ceramics, and the near-infrared fluorescent powder can be obtained by crushing. The XRD pattern of the finally obtained near-infrared phosphor is shown in the attached figure 1 As shown, it can be seen that the near-infrar...

Embodiment 2

[0053] MgO, Al 2 O 3 , SiO 2 and Cr 2 O 3 The powder is weighed according to the formula of the molar ratio of Mg, Al, Si, and Cr elements of 30:19:50:1, and then ground with an agate mortar for 0.5–1 h until the mixture is uniform. The alumina crucible containing the mixed and ground glass matrix raw materials was placed in a high-temperature box furnace in an atmospheric environment, and kept at 1600 ° C for 4 hours; the obtained melt was naturally cooled with the high-temperature box furnace to obtain a green glass matrix, namely The green glass precursor is then put into a high-temperature box furnace in the atmosphere and kept at 1100° C. for 1 hour to obtain a near-infrared fluorescent glass ceramic, which is pulverized to obtain a near-infrared fluorescent powder.

Embodiment 3

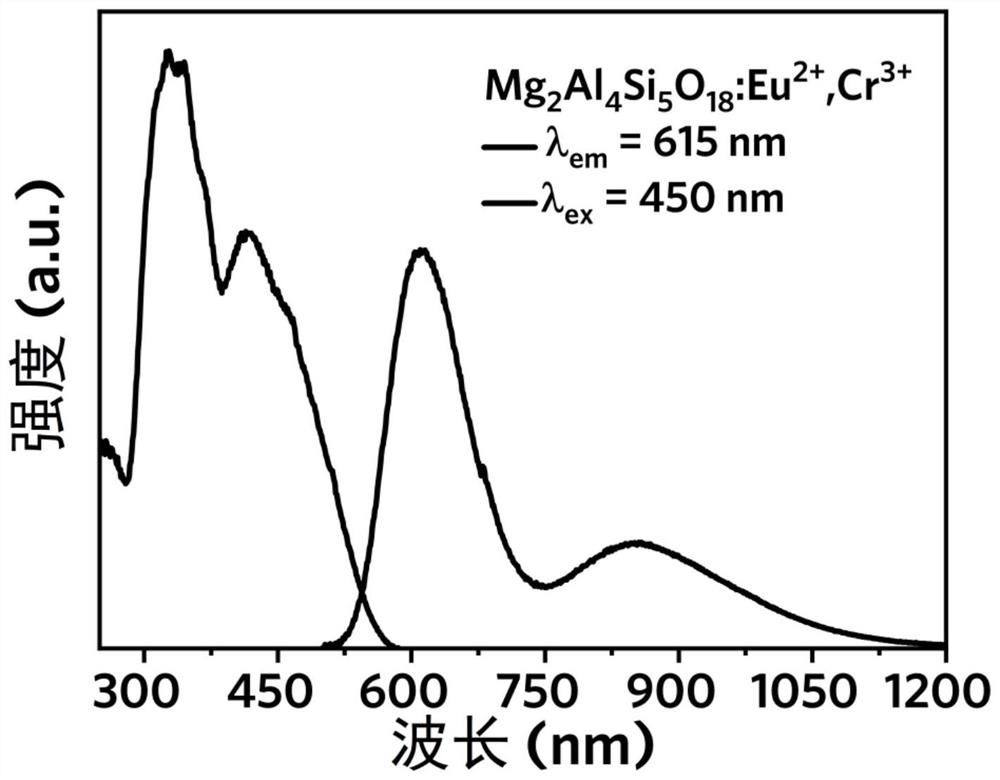

[0055] MgO, Al 2 O 3 , SiO 2 , Eu 2 O 3 and Cr 2 O 3 The powder is weighed according to the formula of Mg, Al, Si, Eu, and Cr with a molar ratio of 29.5:19:50:0.5:1, and then ground with an agate mortar for 0.5–1 h until the mixture is uniform. Put the alumina crucible containing the mixed and ground glass matrix raw materials into the 5% H 2 and 95%N 2 In a tube furnace with a reducing atmosphere, the temperature was kept at 1550°C for 5h. The obtained melt was naturally cooled with a tube furnace to obtain a blue glass matrix, and then the blue glass matrix was put into a 5% H 2 and 95%N 2 A tube furnace in a reducing atmosphere is kept at 1050°C for 1 hour to obtain visible-near-infrared fluorescent glass ceramics, which can be crushed to obtain visible-near-infrared phosphors. The XRD pattern of the final visible-near-infrared phosphor is attached figure 1 As shown, it can be seen that the visible-near-infrared light-emitting material is a single pure phase. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com