Delivery device for biocompatible droplets, manufacturing method and delivery method thereof

A technology of biocompatibility and delivery devices, which is applied in the field of delivery devices for biocompatible droplets, can solve the problems of no biocompatible droplet transportation reports, processing technology limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

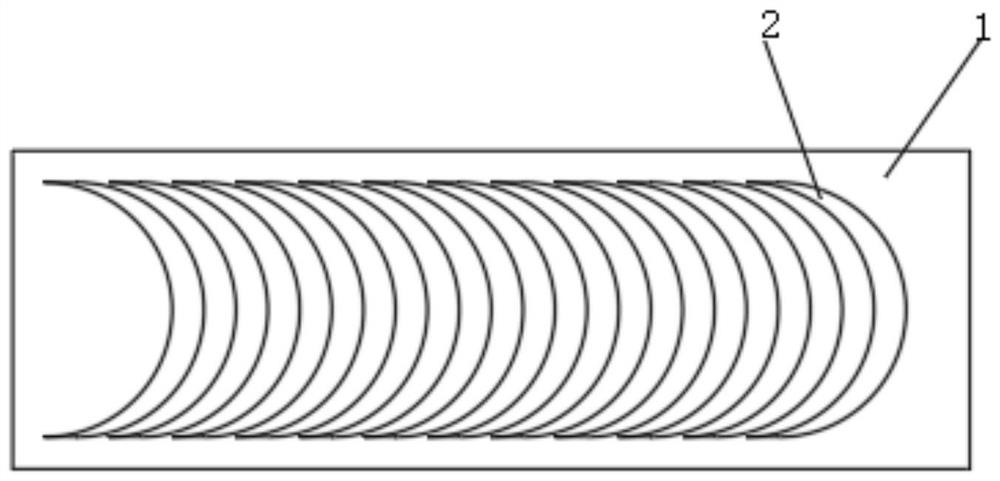

[0055] like figure 1 As shown, the conveying device for biocompatible droplets described in this embodiment includes a base film 1 and a vibrating table, the base film 1 is arranged on the vibrating table, and the vibrating table applies vertical vibration to the base film 1 , so that the droplets located on the base film 1 vibrate periodically in the vertical direction and undergo periodic wetting and dewetting processes. The base film 1 is provided with several arcs 2, and several of the The arcs 2 are distributed in a linear array, forming an anisotropic ratchet array, so that the droplets on the ratchet array are asymmetrically subjected to resistance in all directions; the grooves of the arc 2 are filled with lubricating oil.

[0056]The radius of the circular arc 2 is 2 mm, the depth is 190 μm, and the distance between two adjacent circular arcs 2 is 160 μm.

[0057] The base film 1 adopts polydimethylsiloxane film; polydimethylsiloxane (PDMS) film is widely used in the...

Embodiment 2

[0068] A method for preparing a delivery device for biocompatible droplets, for preparing the delivery device for biocompatible droplets in Example 1, includes the following steps:

[0069] Preparation of S1 base film

[0070] 1.1 Mix the crosslinking agent and the prepolymer in a ratio of 1:12 to obtain a mixture;

[0071] 1.2 Degassing for 10min;

[0072] 1.3 The mixture is deposited on a glass slide placed on a spin coater and then spin-coated; the spin-coater rotates at 200-1000rpm, and the spin-coating time is 0-10min;

[0073] 1.4 Curing on the heating plate at 65°C for 2 hours to form a flat and uniform PDMS film with a thickness of 500 μm;

[0074] 1.5 Cut the PDMS film into several pieces of different sizes for arc processing;

[0075] S2 arc machining

[0076] 2.1 Ultrasonic cleaning of PDMS film with deionized water;

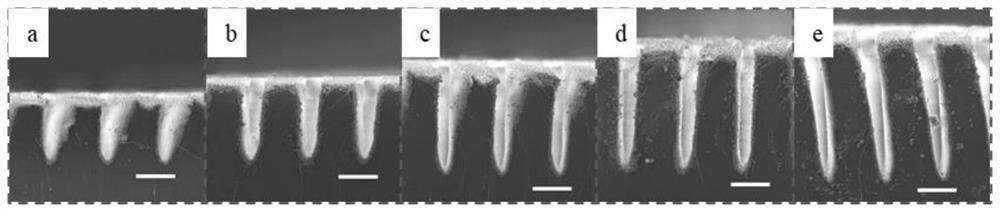

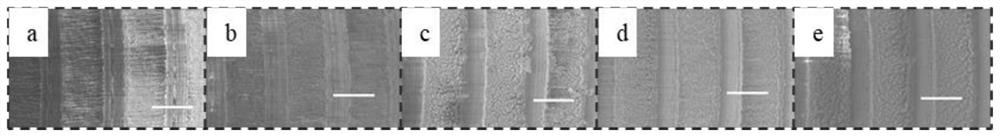

[0077] 2.2 Perform femtosecond laser direct writing on the PDMS film, and the surface of the film forms an arc with a linear array distribution;...

Embodiment 3

[0099] The delivery method of droplets, using the delivery device for biocompatible droplets in Example 1 to deliver droplets;

[0100] S1 drops the droplets into the ratchet array on the PDMS film, so that the droplets are anisotropically resisted in all directions on the PDMS film;

[0101] S2 applies a sinusoidal signal to the vibrating table through the signal generator, so that the vibrating table drives the PDMS film to vibrate vertically, so that the droplet is subjected to an isotropic driving force; the resultant force of the anisotropic resistance and the isotropic driving force is not equal to zero , so that the droplet is subjected to a force in the direction of the resultant force, so that it moves in the direction of the resultant force;

[0102] By adjusting the sinusoidal signal applied by the signal generator to the vibrating table, S3 can drive the frequency and amplitude of the vibration of the PDMS film by the vibrating table, and control the conveying spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com