Nickel monatomic catalyst and preparation method and application thereof

A catalyst and atomic technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Low atomic load and other issues, to achieve the effect of low cost, weakened surface tension, and high loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] One aspect of the present invention provides a method for preparing a nickel single-atom catalyst, comprising the following steps:

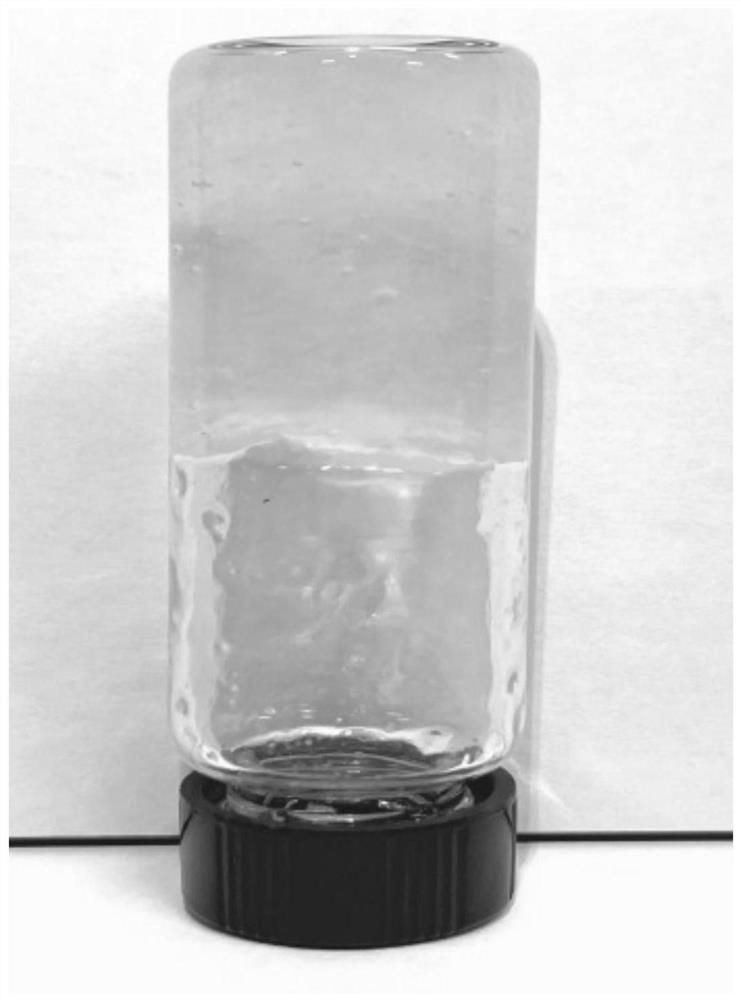

[0041] Provide chitosan sol, sodium silicate aqueous solution and nickel salt aqueous solution respectively; mix sodium silicate aqueous solution and chitosan sol, adjust pH value to 5-7, add nickel salt aqueous solution to prepare reaction system; The reaction system was oscillated with frequency to obtain nickel-chitosan-sodium silicate composite hydrogel; the nickel-chitosan-sodium silicate composite hydrogel was coagulated by supercritical fluid with temperature > 243.1 °C and pressure > 6.39 kPa The glue is dried and carbonized;

[0042] Wherein, the chitosan sol is prepared by dissolving chitosan in an acetic acid aqueous solution to obtain an acid aqueous solution, and the acid aqueous solution is one or more of an acetic acid aqueous solution, a citric acid aqueous solution and an aqueous hydrochloric acid solution.

[0043] By us...

Embodiment 1

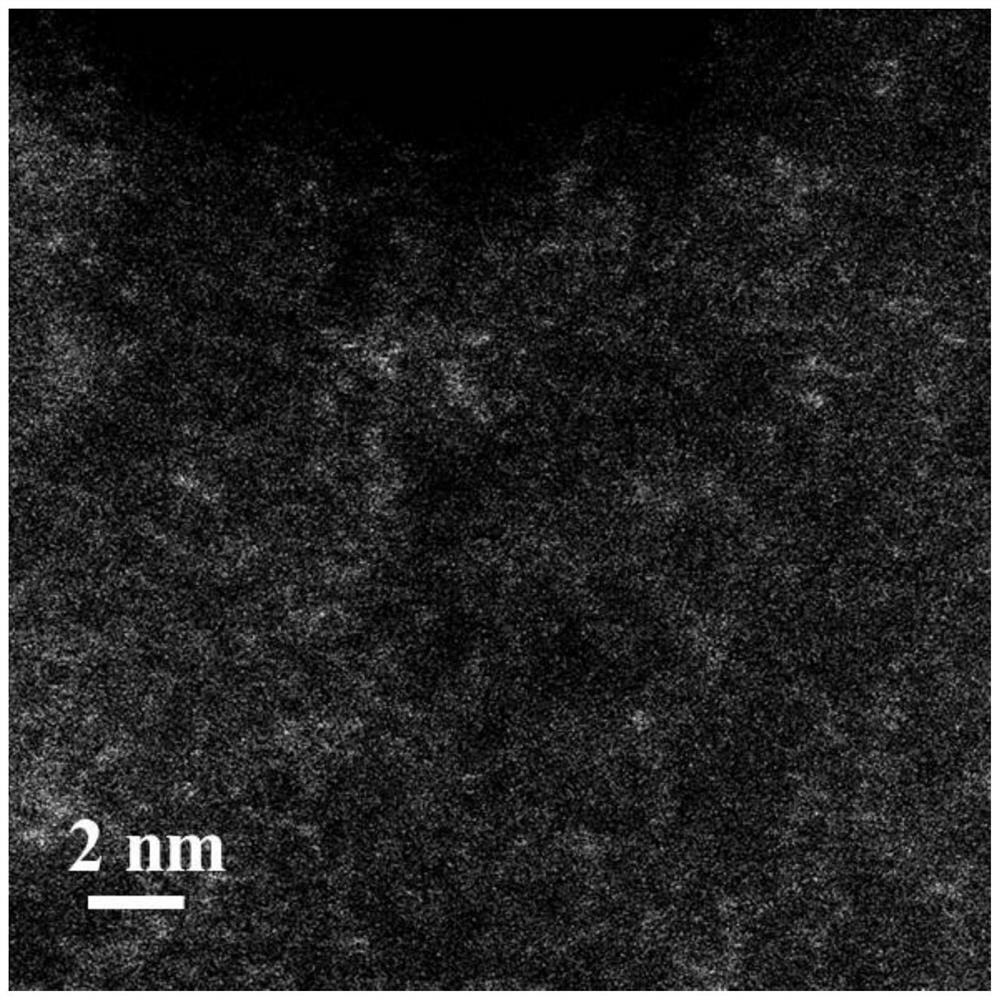

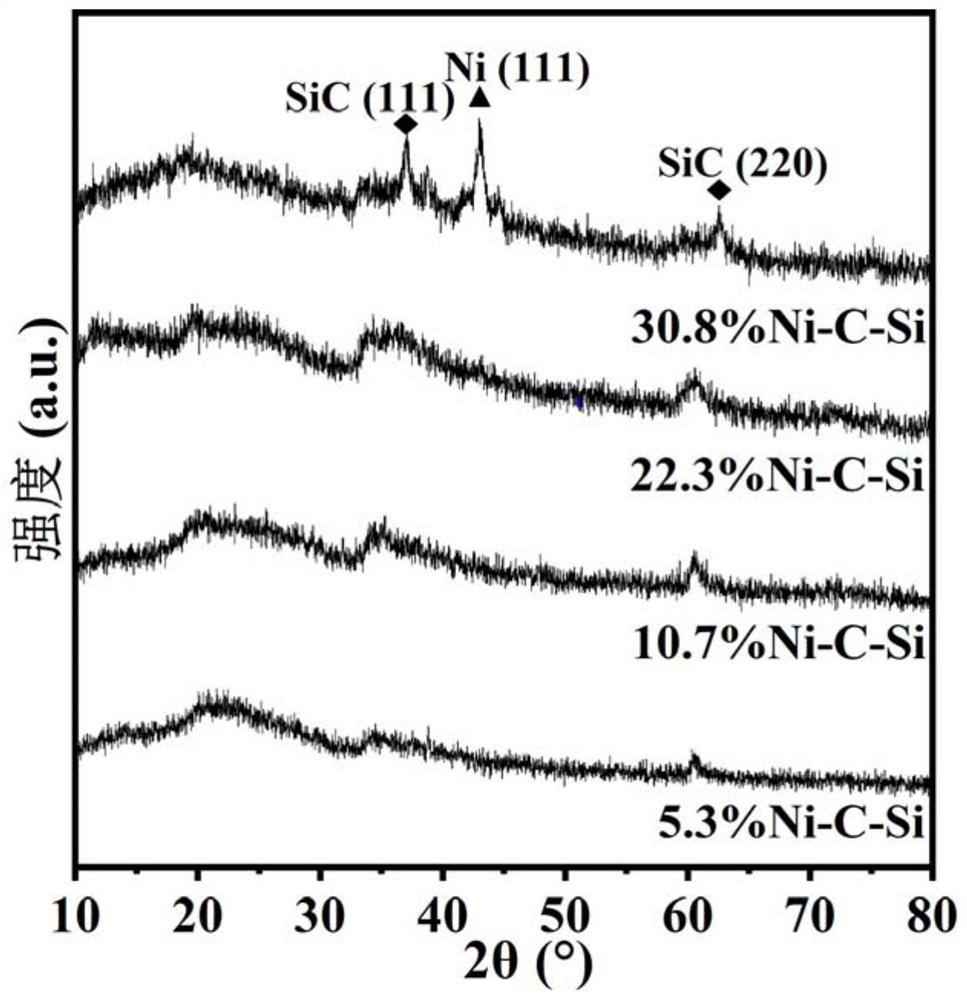

[0073] 10 mL of sodium silicate solution (Na 2 O and SiO 2 The ratio of the amount of substances is 1:1, SiO 2 Concentration 100mg / mL) was added to 40mL of chitosan sol with a concentration of 50mg / mL (solvent: acetic acid aqueous solution with a mass percentage of 1%), adjusted pH to 6.5 after thorough mixing, and then added 3.16mL of freshly prepared nickel nitrate Solution (50mg / L, with Ni 2+ The reaction system was immediately oscillated at a frequency of 50 Hz with a vortex mixer, and the ternary system was ultra-fast co-gelated within 2 s to obtain a homogeneous nickel-chitosan-sodium silicate composite hydrogel; temperature and The nickel-chitosan-sodium silicate composite hydrogel was simultaneously dried and carbonized for 4 h with ethanol supercritical fluid at 300 °C and 10 kPa, respectively, to obtain a nickel single-atom catalyst with a nickel single-atom loading of 5.3%. As 5.3% Ni-C-Si.

Embodiment 2

[0075] 10 mL of sodium silicate solution (Na 2 O and SiO 2 The ratio of the amount of substances is 1:1, SiO 2 Concentration 100mg / mL) was added to 40mL of chitosan sol with a concentration of 50mg / L (solvent: acetic acid aqueous solution with a mass percentage of 1%), adjusted pH to 6.5 after thorough mixing, and then added 6.67mL of freshly prepared nickel nitrate Solution (50mg / L, with Ni 2+ The reaction system was immediately oscillated at a frequency of 50 Hz with a vortex mixer, and the system ultra-fast co-gelation within 2 s to obtain a homogeneous nickel-chitosan-sodium silicate composite hydrogel, denoted as 10% Ni -CS-Si; The nickel-chitosan-sodium silicate composite hydrogel was dried and carbonized for 4 h by using ethanol supercritical fluid with temperature and pressure of 300 °C and 10 kPa, respectively, to obtain a nickel single atom loading of 10.7%. Nickel single-atom catalyst, denoted as 10.7% Ni-C-Si.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com