Common-method caramel color production process and caramel color

A production process, the technology of common method caramel, is applied to the common method caramel color production process and caramel color. It can solve the problems of caramel color and water-insoluble matter, and achieve the effect of low viscosity, reducing the formation of water-insoluble matter and improving sensory quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

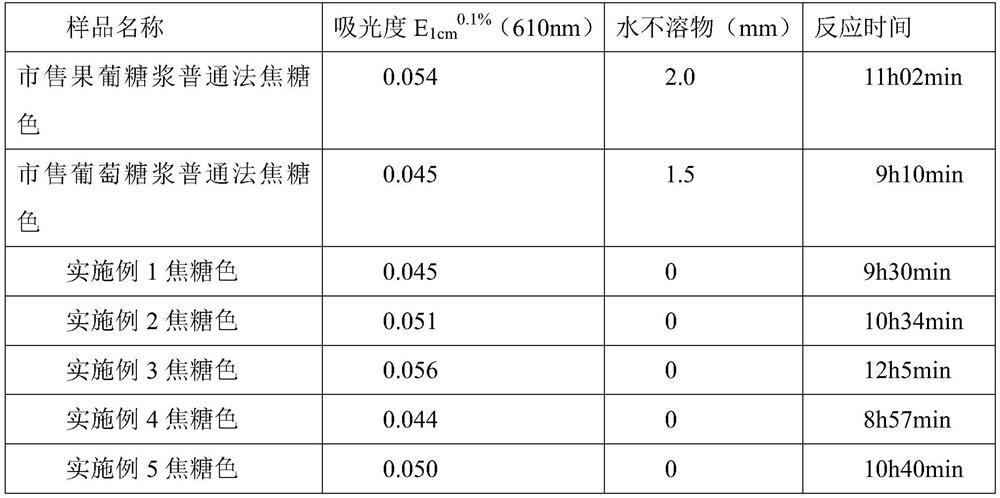

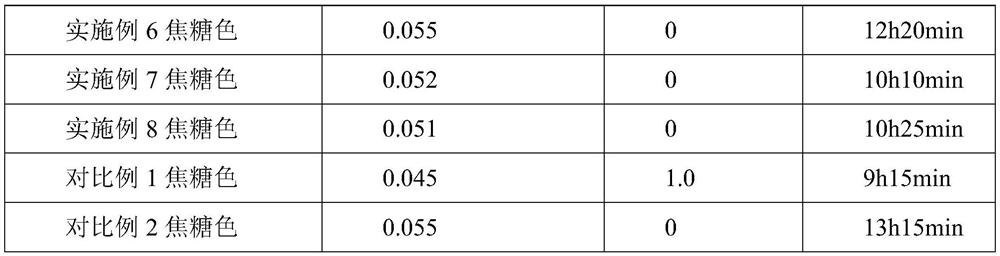

Examples

Embodiment 1

[0035] Example 1 (10m 3 Reactor, fructose syrup added 5% sorbitol (dry basis)):

[0036] A common method caramel color production process, comprising the following steps:

[0037] S1, raw material metering and feeding: measure 8451kg high fructose syrup (F42, dry basis is 71.0%) with a metering pump and pump into the reactor;

[0038] S2, ingredients: weigh 441kg of sorbitol (dry basis is 68.0%) and put it into the reaction kettle, and mix it with high fructose syrup;

[0039] S3, caramelization reaction: turn on the reactor stirrer, then turn on the steam to heat up the syrup to boiling (103°C) in the reactor and maintain the boiling state, the syrup is gradually concentrated, and the temperature is gradually increased. When the temperature reaches about 140 degrees Celsius, the syrup begins to change color. , control the maximum temperature not to exceed 160 ℃, check the color price, when the color price reaches 0.060, turn off the steam, add an appropriate amount of water...

Embodiment 2

[0041] Example 2 (10m 3 Reactor, fructose syrup added 10% sorbitol (dry basis)):

[0042] A common method caramel color production process, comprising the following steps:

[0043] S1, raw material metering and feeding: measure 8451kg high fructose syrup (F42, dry basis is 71.0%) with a metering pump and pump into the reactor;

[0044] S2, ingredients: weigh 882kg of sorbitol (dry basis is 68.0%) and put it into the reaction kettle, and mix it with high fructose syrup;

[0045]S3. Caramelization reaction: turn on the agitator of the reactor, then turn on the steam to heat up the syrup to boiling (103°C) in the reactor and maintain the boiling state, the syrup is gradually concentrated, and the temperature is gradually increased. When the temperature reaches about 140°C, the syrup begins to change color. , control the maximum temperature not to exceed 160 ℃, check the color price, when the color price reaches 0.070, turn off the steam, add an appropriate amount of water, and ...

Embodiment 3

[0047] Example 3 (10m 3 Reactor, fructose syrup added 20% sorbitol (dry basis)):

[0048] A common method caramel color production process, comprising the following steps:

[0049] S1, raw material metering and feeding: measure 8451kg high fructose syrup (F42, dry basis is 71.0%) with a metering pump and pump into the reactor;

[0050] S2, ingredients: weigh 1764kg of sorbitol (dry basis is 68.0%) and put it into the reaction kettle, and mix it with high fructose syrup;

[0051] S3. Caramelization reaction: turn on the agitator of the reactor, then turn on the steam to heat up the syrup to boiling (103°C) in the reactor and maintain the boiling state, the syrup is gradually concentrated, and the temperature is gradually increased. When the temperature reaches about 140°C, the syrup begins to change color. , control the maximum temperature not to exceed 160 ℃, check the color price, when the color price reaches 0.080, turn off the steam, add an appropriate amount of water, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com