Composite material, quantum dot light emitting diode and preparation method of quantum dot light emitting diode

A quantum dot light-emitting and composite material technology, applied in the field of quantum dot light-emitting diodes, can solve the problem of low carrier transmission efficiency, achieve the effects of improving luminous efficiency, improving stability, and promoting recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

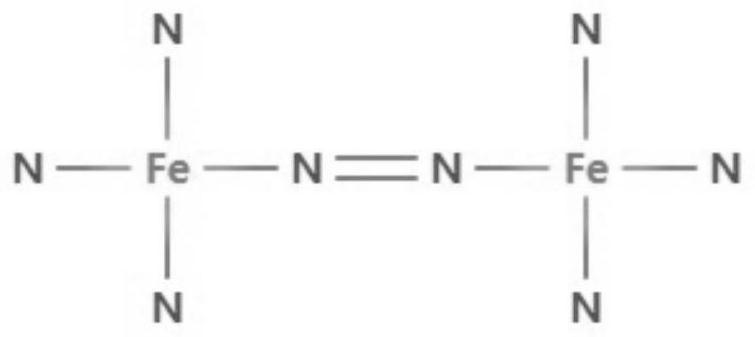

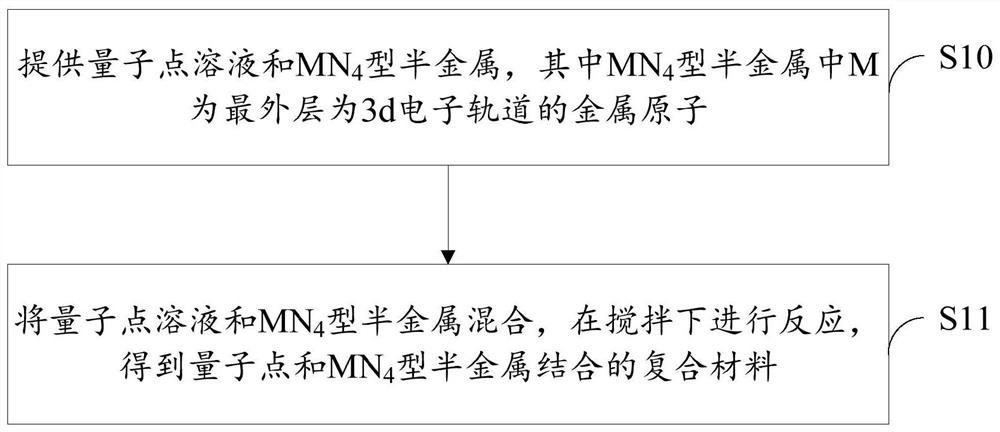

[0101] FeN in this example 4 The preparation steps of -CdS / ZnS composites are as follows:

[0102] 1), the appropriate amount of FeCl 3 and ammonium chloride were dissolved in 10 ml of dimethyl sulfoxide (molar ratio, Fe:N=1:5), after ultrasonic dissolution, the mixed solution was transferred to a high-pressure high-temperature reaction kettle. First, apply a high pressure of 10GPa to the reaction raw materials. After the pressure rises to a predetermined pressure, the temperature is raised to 300 ° C, and the temperature is maintained for 2 hours. Finally, the temperature is lowered at a fixed pressure. After cooling to room temperature, pressure relief treatment is performed to obtain FeN. 4 type semi-metal;

[0103] 2), adding an appropriate amount of CdS / ZnS quantum dots into 20 ml of ODE to form a quantum dot solution with a concentration of 20 mg / mL. Subsequently, the temperature was raised to 200°C in an argon atmosphere, and then thioglycolic acid (volume ratio, qua...

Embodiment 2

[0106] In this example, MnN 4 -Cd 1-x Zn x The preparation steps of the S composite material are as follows:

[0107] 1), the appropriate amount of MnCl 2 and urea were dissolved in 10 mL of N,N-dimethylformamide (molar ratio, Mn:N=1:6), and after ultrasonic dissolution, the mixed solution was transferred to a high-pressure high-temperature reaction kettle. First, apply a high pressure of 12GPa to the reaction raw materials. After the pressure rises to a predetermined pressure, the temperature is raised to 350 °C, and the temperature is maintained for 3 hours. Finally, the temperature is lowered at a fixed pressure. After cooling to room temperature, pressure relief treatment is performed to obtain MnN 4 type semi-metal;

[0108] 2), put an appropriate amount of Cd 1-x Zn x S quantum dots were added to 20 ml of 1-hexadecene to form a quantum dot solution with a concentration of 30 mg / mL. Subsequently, the temperature was raised to 200° C. in an argon atmosphere, followed ...

Embodiment 3

[0111] CoN in this embodiment 4 -Cd 1-x Zn x The preparation steps of S / ZnS composites are as follows:

[0112] 1), the appropriate amount of CoCl 2 and urea were dissolved in 10 mL of tetrahydrofuran (molar ratio, Co:N=1:7), after ultrasonic dissolution, the mixed solution was transferred to a high-pressure high-temperature reaction kettle. First, apply a high pressure of 15GPa to the reaction raw materials. After the pressure rises to a predetermined pressure, the temperature is raised to 400 °C, and the temperature is maintained for 2 hours. Finally, the temperature is lowered at a fixed pressure. After cooling to room temperature, pressure relief treatment is performed to obtain CoN. 4 type semi-metal;

[0113] 2), put an appropriate amount of Cd 1-x Zn x S / ZnS quantum dots were added to 20 ml of 1-eicosene to form a quantum dot solution with a concentration of 50 mg / mL. Subsequently, the temperature was raised to 200°C in an argon atmosphere, and then mercaptoethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com