High-strength lightweight stab-resistant material and preparation method thereof

A lightweight, high-strength technology, applied in fiber processing, textile and papermaking, fiber types, etc., it can solve the problems of complex preparation process, poor liquid-wet penetration, poor flexibility, etc., to achieve good softness, enhanced The effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0039] Mix 100g epoxy resin E51 and 30g butyl acrylate BA into a three-necked flask with nitrogen protection, heat to 50°C and mix evenly for 60min, add 5g of initiator AIBN to dissolve, then raise the temperature to 60°C, and keep the temperature for 6h. The butyl acrylate-modified epoxy resin mixture toughening agent has a viscosity of 10,000-30,000 cps at room temperature.

Synthetic example 2

[0041] Mix 100g epoxy resin E51 and 30g isooctyl acrylate EHA into a three-necked flask with nitrogen protection, heat to 50°C and mix for 60min, add 5g initiator AIBN to dissolve, then raise the temperature to 70°C, and keep the temperature for 6h. A toughening agent of epoxy resin mixture modified with butyl acrylate is obtained, and the viscosity of the obtained toughening agent is 10000-20000 cps at room temperature.

Synthetic example 3

[0043]100g of E51 resin, 15g of butyl acrylate BA and 15g of isooctyl acrylate EHA were mixed into a three-necked flask with nitrogen protection, heated to 50°C and uniformly mixed for 60min, and 5g of initiator AIBN was added to dissolve and then the temperature was raised to 60°C, After lasting for 6 hours, a toughening agent of epoxy resin mixture modified with butyl acrylate is obtained, and the viscosity of the obtained toughening agent is 20000-30000 cps at room temperature.

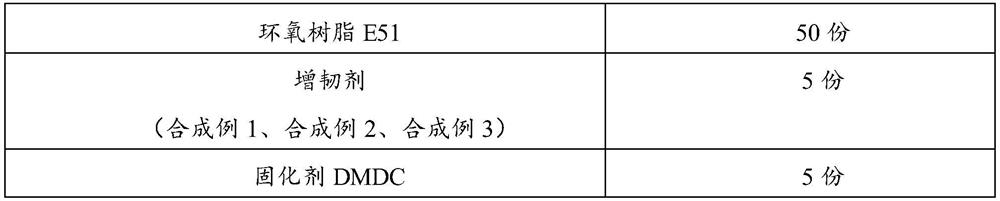

[0044] To evaluate the toughening effect of toughening agent, elongation at break and impact strength are used to characterize the toughening effect of toughening agent on epoxy resin. The test method of elongation at break refers to GB / T3923.1-1997, and the impact strength is tested under the condition of impact test machine and impact energy of 24J. The test formula reference is as follows:

[0045]

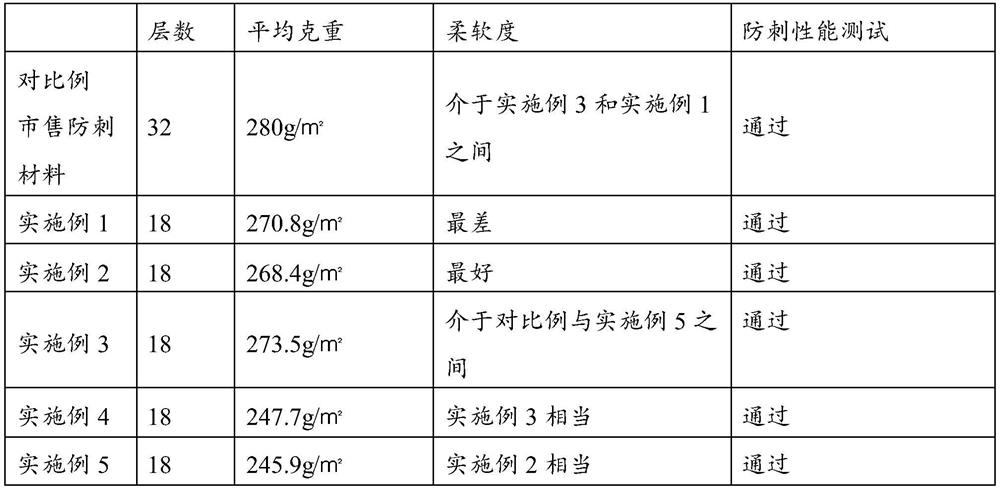

[0046] The test results are as follows:

[0047] Elongation at break Impact st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com