Process preparing red dye film of writable high-density digital optical disc

A technology of digital discs and dye films, applied in the manufacture of optical record carriers, optical record carriers, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 150mg of the above-mentioned azo dye and add it to 10ml tetrafluoropropanol;

[0019] Dissolve the above solution in an ultrasonic tank for 2 hours with ultrasonic vibration, then filter it with microfilters with a pore size of 0.5 μm and 0.2 μm, and transfer the filtered solution to a storage bottle;

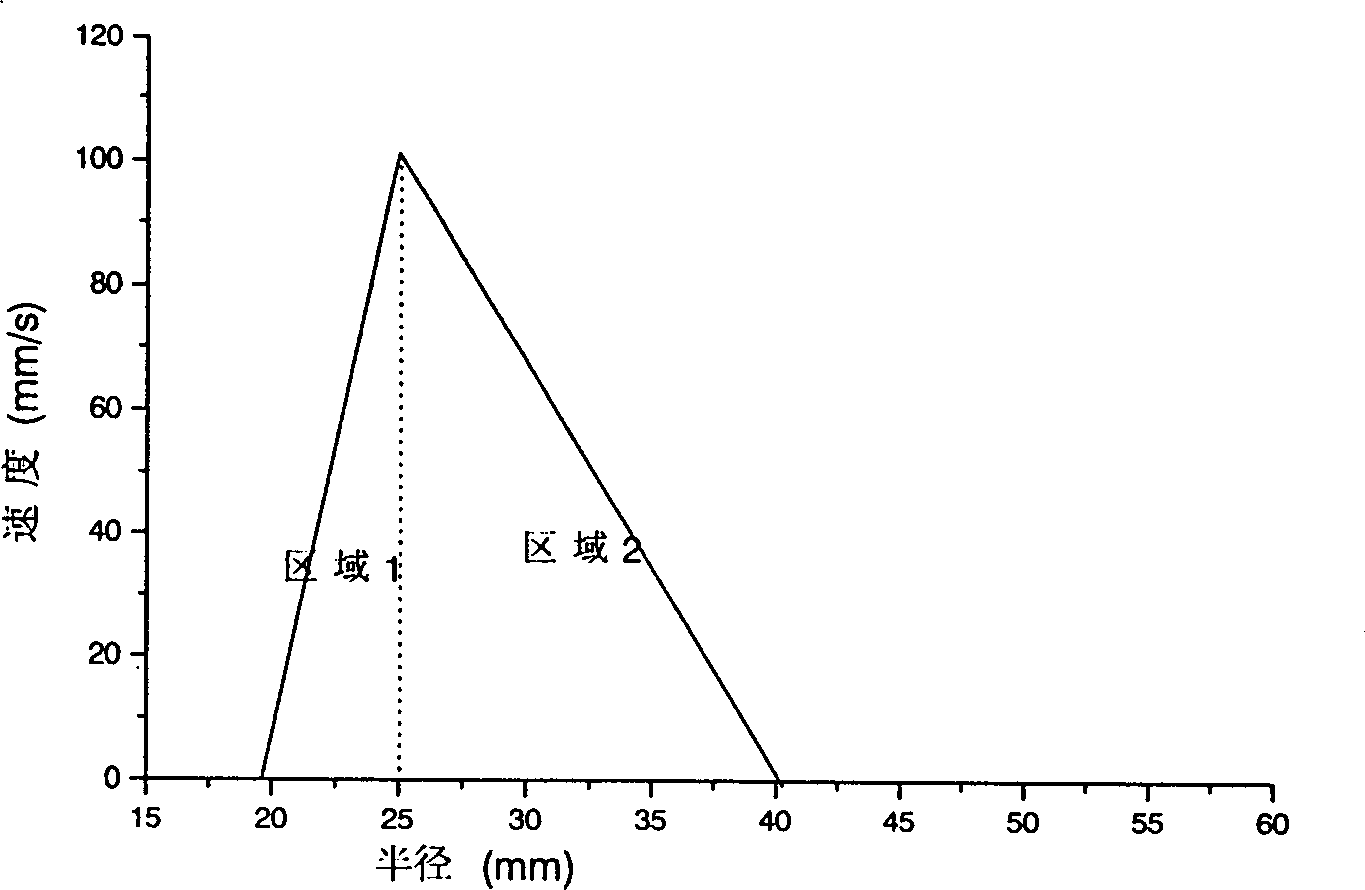

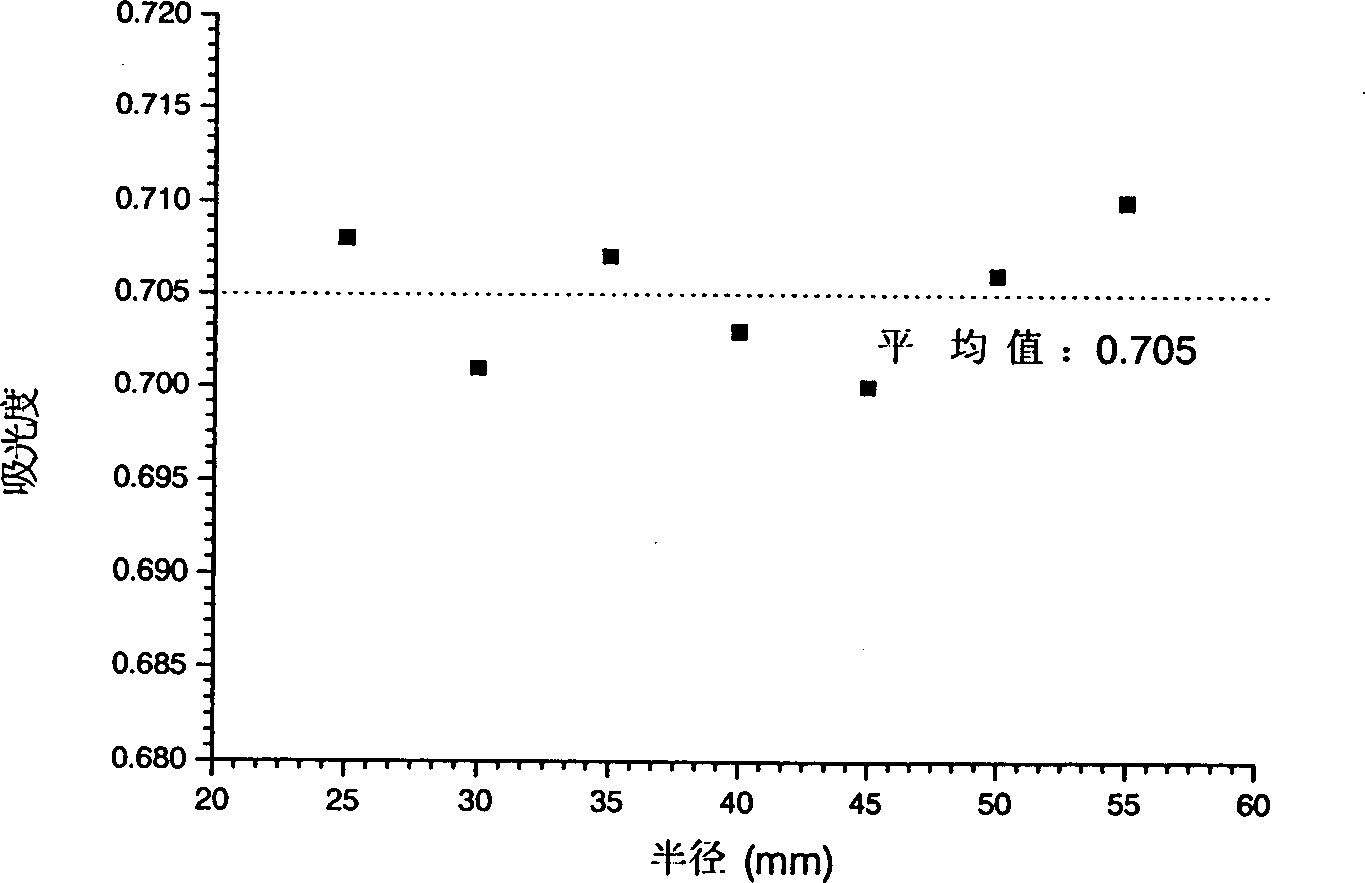

[0020] The length of the first area 1 of the feeding hand movement in the spin coating equipment is 5mm, and the acceleration is 100mm / s 2 ;The length of the second zone 2 is 10mm, and the acceleration is 80mm / s 2 ; Feed amount 0.2ml; feed speed 200 rpm, glue equalization speed 1000 rpm, time 4s, drying speed 3500 rpm, time 2s. The uniformity of the dye film was 0.83%.

Embodiment 2

[0022] Weigh 200mg of the above-mentioned azo dye and add it to 10ml tetrafluoropropanol;

[0023] Same as above;

[0024] The length of the first area 1 of the feeding hand movement in the spin coating equipment is 10mm, and the acceleration is 150mm / s 2 ;The length of the second zone 2 is 15mm, and the acceleration is 100mm / s 2 ; Feed amount 0.2ml; feed speed 200 rpm, glue equalization speed 1000 rpm, time 4s, drying speed 3500 rpm, time 2s. The uniformity of the dye film was 0.91%.

Embodiment 3

[0026] Weigh 300mg of the above-mentioned azo dye and add it to 10ml tetrafluoropropanol;

[0027] Same as above;

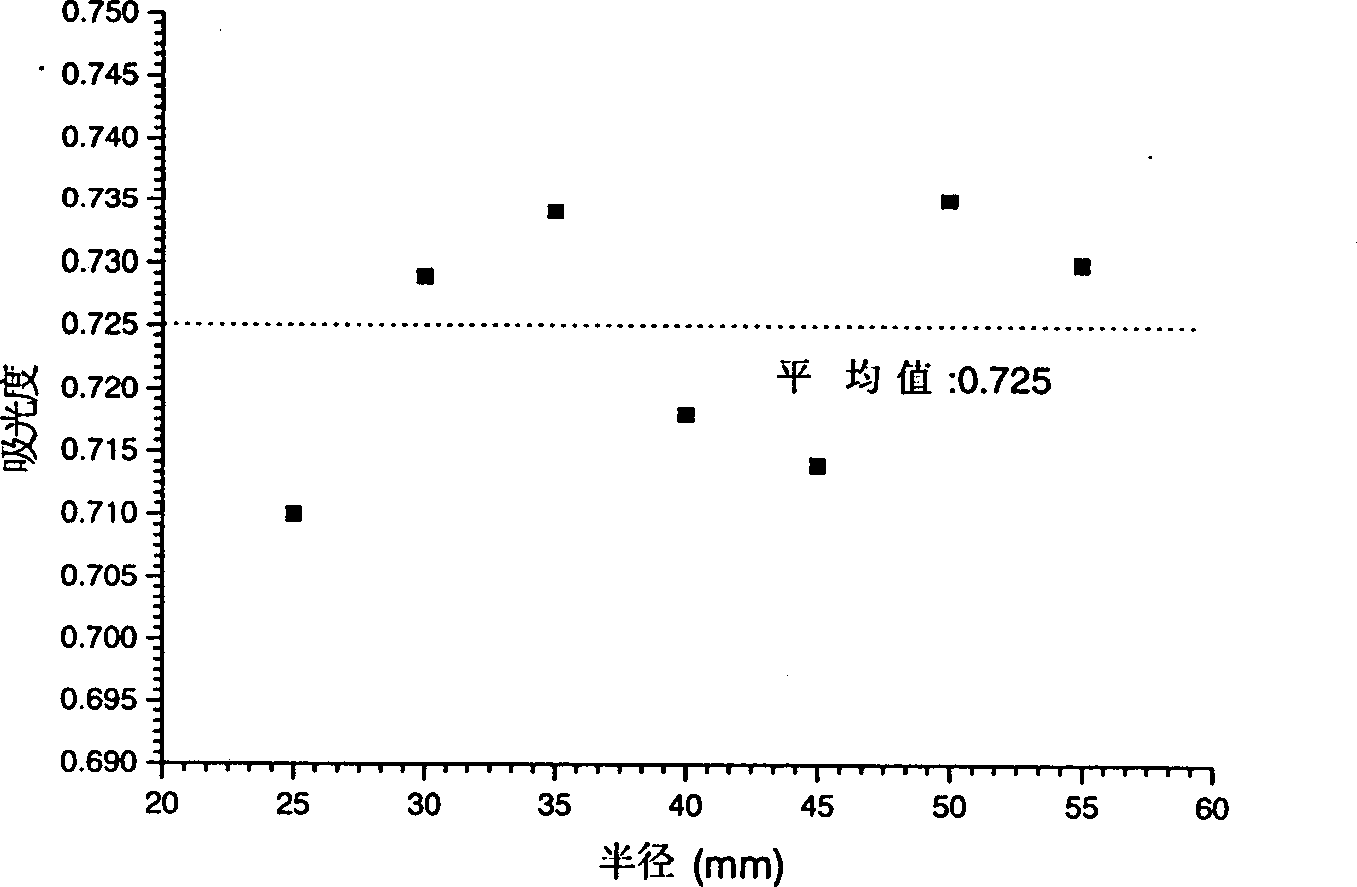

[0028] The length of the first area 1 of the feeding hand movement in the spin coating equipment is 10mm, and the acceleration is 200mm / s 2 ;The length of the second zone 2 is 15mm, and the acceleration is 120mm / s 2 ; Feed amount 0.2ml; feed speed 200 rpm, glue equalization speed 1000 rpm, time 4s, drying speed 3500 rpm, time 2s. The uniformity of the dye film was 0.97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com