Internal tension reducing system for cruciate ligament reconstruction and mechanical manufacturing process of internal tension reducing system

A cruciate ligament and tension-reducing wire technology, which is applied in the posterior cruciate ligament reconstruction and anterior field, can solve problems such as inconsistent elastic modulus, insufficient tension-reducing wire strength, and inability to fully exert the tension-reducing effect, so as to prevent elongation and effectively Facilitate religamentization and prevent early fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] S1: Preparation of raw materials

[0034] Two No. 2 ultra-high molecular weight polyethylene (UHMWPE) non-absorbable surgical sutures were prepared as raw materials, and the sutures were required to be free of roughness, cracks and breaks.

[0035] S2: Fixation of raw materials

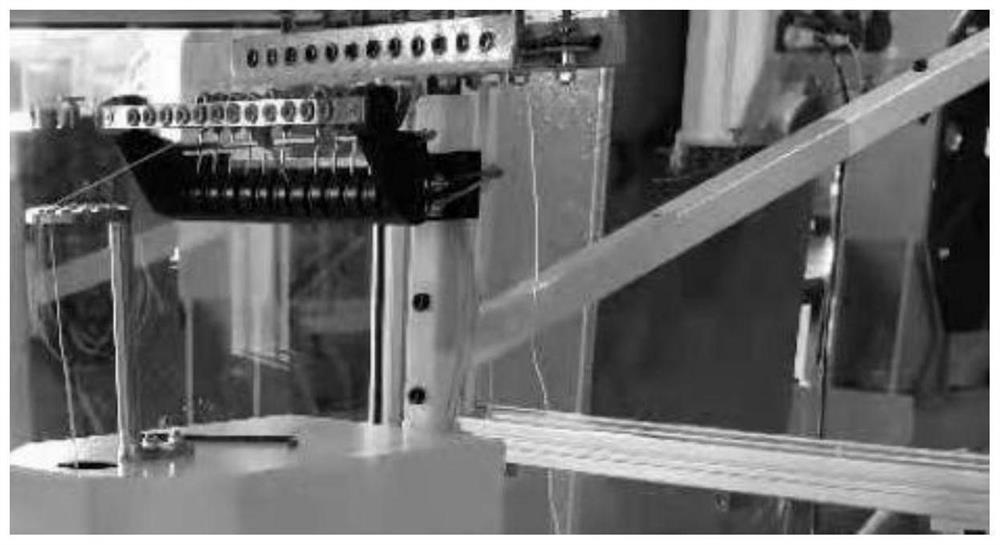

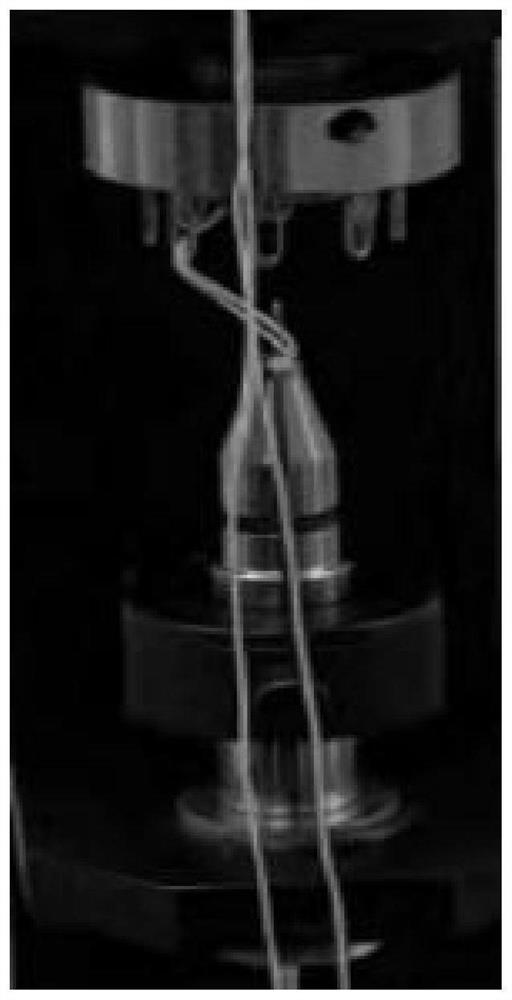

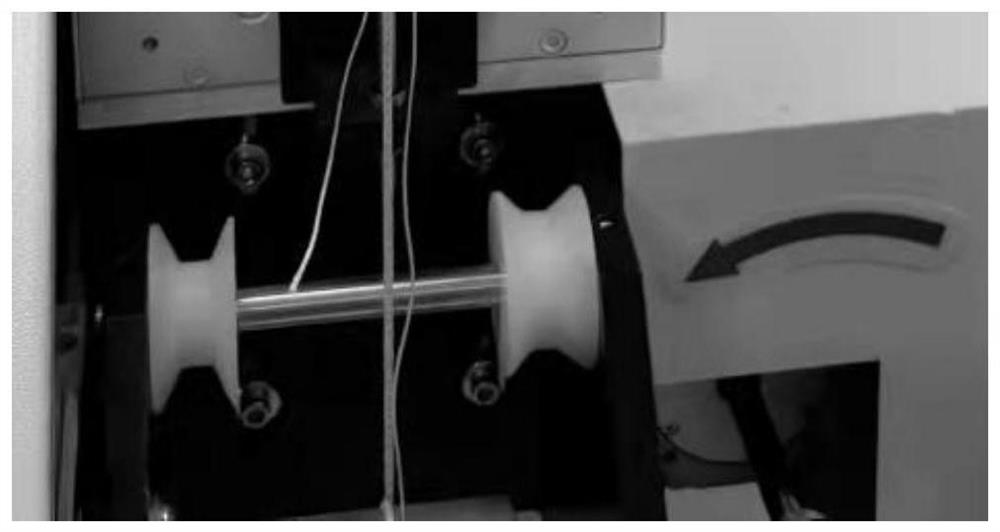

[0036] Wind the prepared suture raw material on the yarn tube through the winding machine; figure 1 ); pass the raw material through the tension threader to keep the raw material knitted under a tension of 80N; pass the raw material through the ceramic magnetic hole and hang it on the crochet needle in the main work area (such as figure 2 ), and then fix the thread end on the take-up wheel through the take-up device (such as image 3 ).

[0037] S3: Set braiding machine parameters

[0038] Turn on the knitting machine to set knitting parameters (such as Figure 4 ), the main motor speed is 120r / min, the weaving pitch is 4mm, the weave length is set to 100m, the percentage of closing torqu...

Embodiment 2

[0049] Research on the performance of the tension reduction line;

[0050] 1) Research and preparation instructions for product technical requirements

[0051] The technical requirements of the product are mainly formulated in accordance with YY 0167-2005; the standards referenced and quoted in the formulation of the technical requirements of this product are as follows:

[0052] YY 0167-2005 Non-absorbable surgical sutures

[0053] GB / T14233.1-2008 Test methods for medical infusion, blood transfusion and injection equipment - Part 1: Chemical analysis methods

[0054] GB / T14233.2-2005 Test methods for medical infusion, blood transfusion and injection equipment - Part 2: Biological test methods

[0055] 2) Function, safety and other indicators related to quality control, see Table 1;

[0056] Table 1 Functionality, safety and other indicators related to quality control

[0057]

[0058] 3) Mechanical properties study; see Table 2

[0059] Table 2 Test results of mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap