Machining grinding tool positioning and adjusting device

A positioning adjustment and machining technology, applied in grinding/polishing safety devices, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to guarantee the effect of grinding position, shorten the service life of equipment, and long grinding time, so as to avoid accidents The effect of breaking and adjusting the work is simple and convenient, and the yield is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

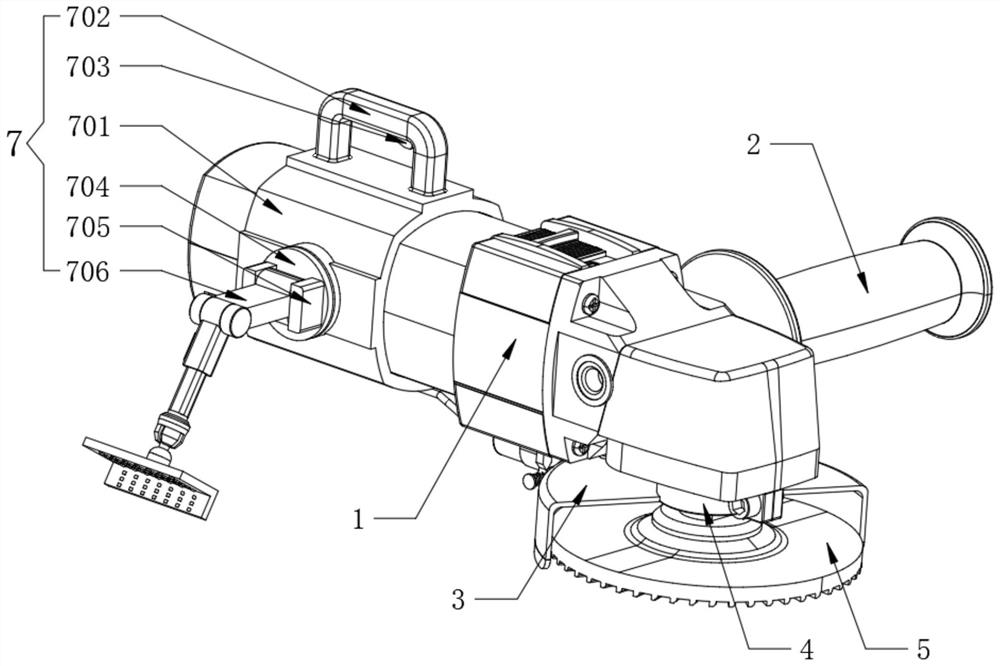

[0041] Refer to the attached Figure 5 and Image 6 , the positioning adjustment assembly 7 also includes an assembly shell 701 and a right-angle plate 713. The assembly shell 701 is sleeved on the outer surface of the grinding machine 1, the side surface of the assembly shell 701 is rotatably installed with a turntable 704, and both sides of the outer wall of the turntable 704 are fixedly provided with rotary The first seat 705, the inner sides of the two turning bases 705 are rotatably connected with the main turning rod 706, the two turning bases 707 are fixedly arranged on both sides of the end of the main turning rod 706, and the inner sides of the two turning bases 707 are rotatably connected with auxiliary turning Rod 708, the side wall of the auxiliary rotation rod 708 is fixedly provided with a side card slot 712, the inner part of the auxiliary rotation rod 708 is movably inserted with an insert rod 709, and the end of the auxiliary rotation rod 708 is fixedly provid...

Embodiment 2

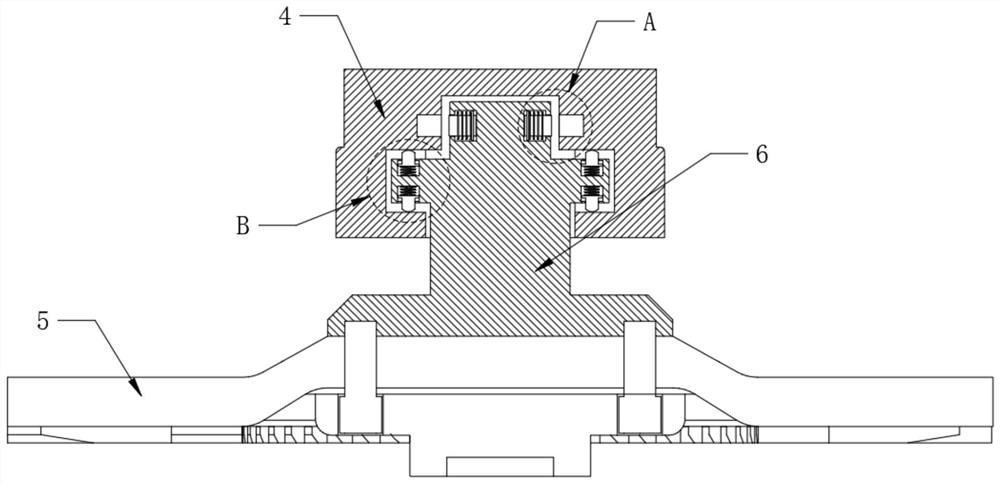

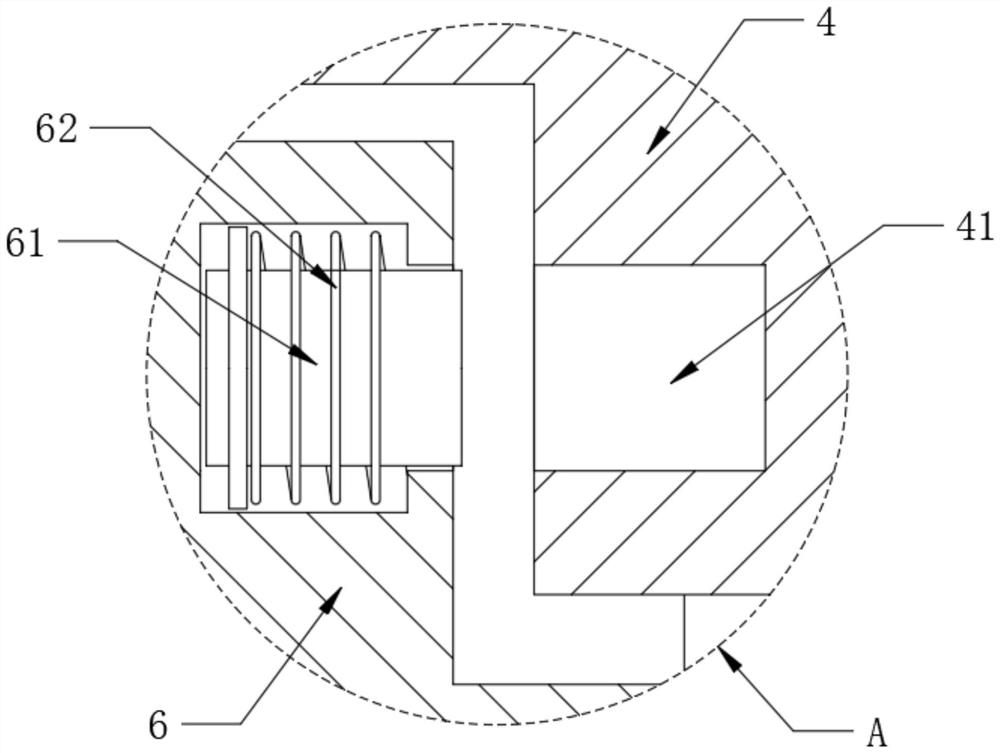

[0045] Refer to the attached Figure 2-4 The top end of the working shaft 4 is equidistantly fixed with locking holes 41 , and the bottom end of the working shaft 4 is equidistantly fixed with offset grooves 42 .

[0046] Refer to the attached image 3 , the inside of the top edge of the inscribed shaft 6 is movably installed with a locking block 61, the outer surface of the locking block 61 is sleeved with a spring 62, and the end of the locking block 61 is movably inserted into the inside of the locking hole 41, The cross-sectional area of the locking block 61 is the same as the cross-sectional area of the locking hole 41. During the high-speed rotation of the grinding wheel 5 driven by the working shaft 4, each locking block 61 will move away from the center of rotation under the action of centrifugal force. , and is inserted into the corresponding locking hole 41 , and no offset will occur between the working shaft 4 and the inscribed shaft 6 .

[0047] Refer to the ...

Embodiment 3

[0050] Refer to the attached Figure 9 , the transmission assembly 8 also includes a built-in rod 801, the built-in rod 801 is movably inserted inside one side of the wheel cover 3, the bottom of the built-in rod 801 is fixedly provided with a baffle-804, the upper surface of the baffle-804 and the lower surface of the wheel-cover 3 are between They are connected by a spring three 805, and the spring three 805 is sleeved on the outer surface of the built-in rod 801. The bottom end of the built-in rod 801 is rotated and provided with a fitting wheel 802, and the outer wall of one end of the fitting wheel 802 is fixedly connected with a connecting rod. 803 , a displacement slot 31 is fixedly opened on one side of the wheel housing 3 , and the connecting rod 803 is movable through the displacement slot 31 .

[0051] Refer to the attached Figure 10 , a support 806 is fixed on one side of the lower surface of the grinding machine 1, and a tension rod 807 is movably interspersed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com