High-phosphorus food industry wastewater treatment method and treatment system thereof

A technology of industrial wastewater and treatment method, which is applied in the fields of food industry wastewater treatment, water/sewage multi-stage treatment, flotation water/sewage treatment, etc., can solve the problem of unstable phosphorus removal effect, secondary pollution treatment cost, and inorganic phosphorus removal. problems such as poor effect, to achieve the effect of stable operation, low investment and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

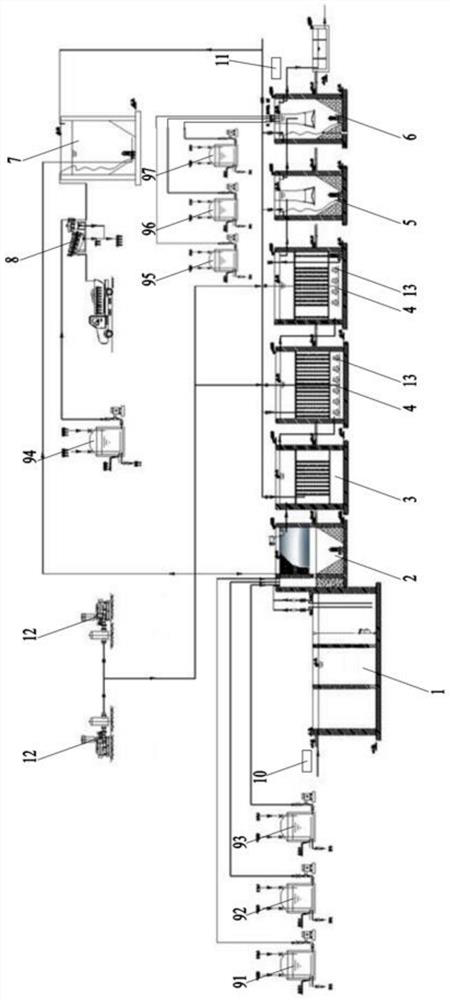

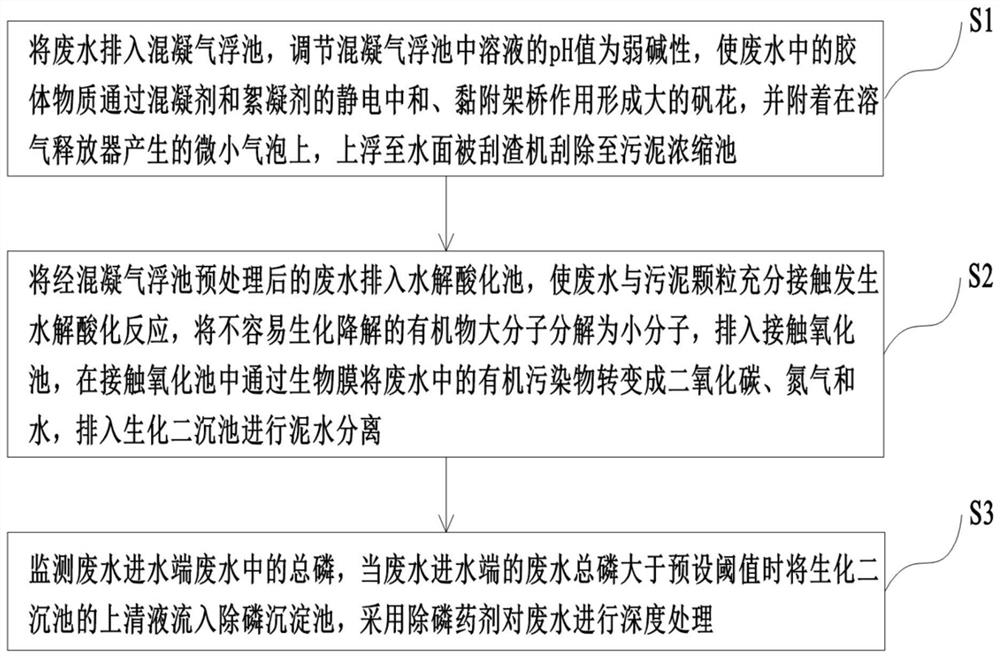

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

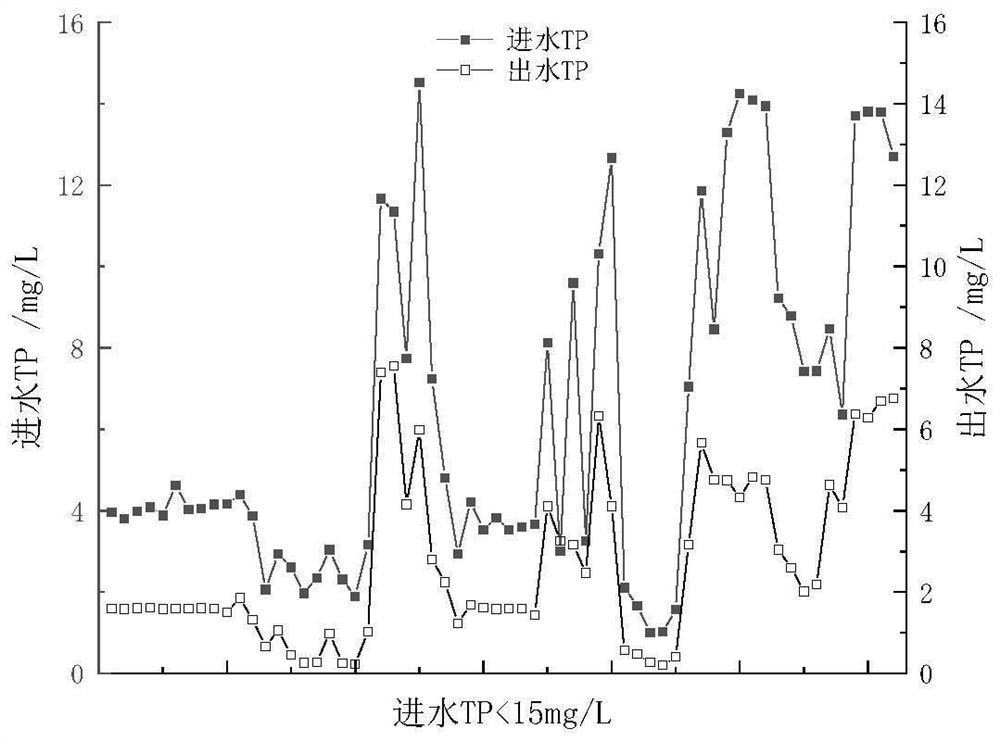

[0023] In the process of producing and processing aquatic products such as prawns, aquatic product processing enterprises produce high-concentration organic wastewater. prone to corruption. The concentration of dissolved organic phosphorus in water is between 50 and 220 mg / L, and the chemical oxygen demand (COD) Cr ), five-day biochemical oxygen demand (BOD 5 ), ammonia nitrogen (NH 3 -N), suspended solids (SS), these pollutants ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com