Sintering process of tape casting aluminum oxide sheet

A technology of tape casting and alumina, which is applied in the direction of improving process efficiency, can solve the problems of production efficiency decline and cost increase, and achieve the effects of reducing firing time, saving production cost and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

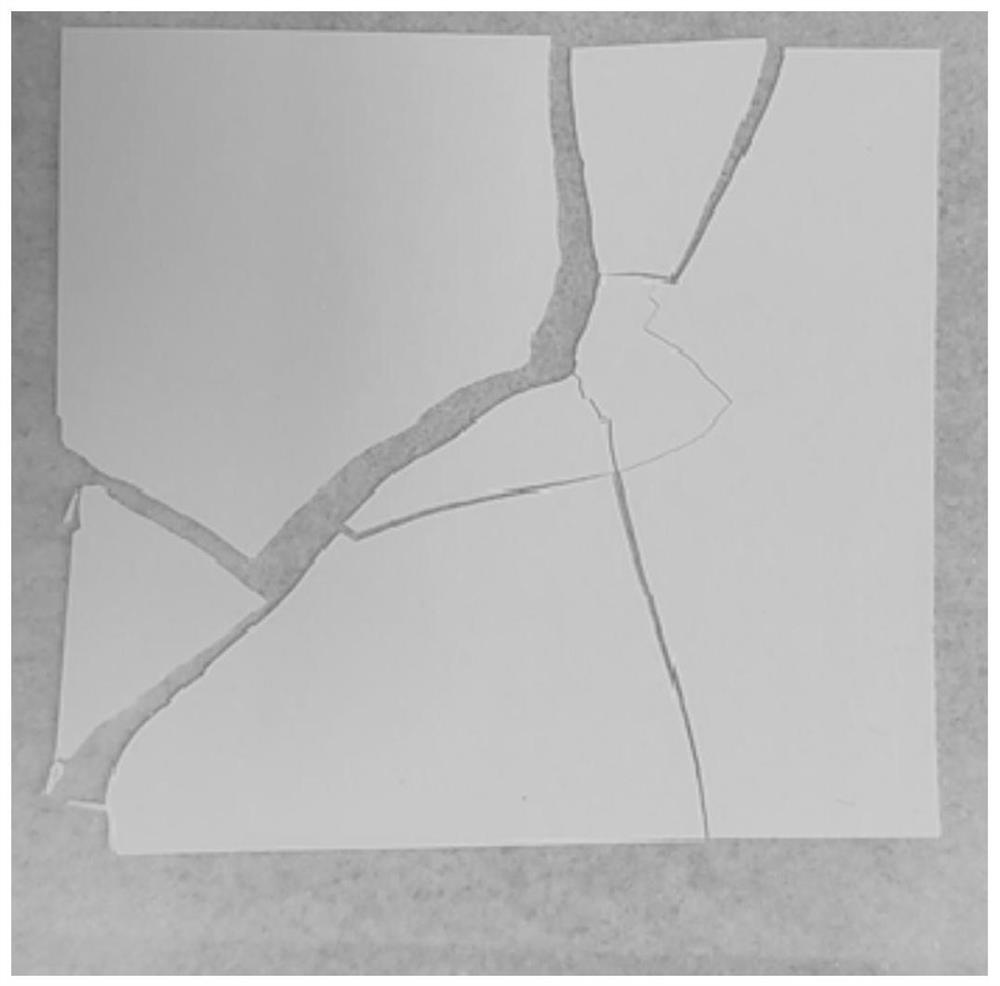

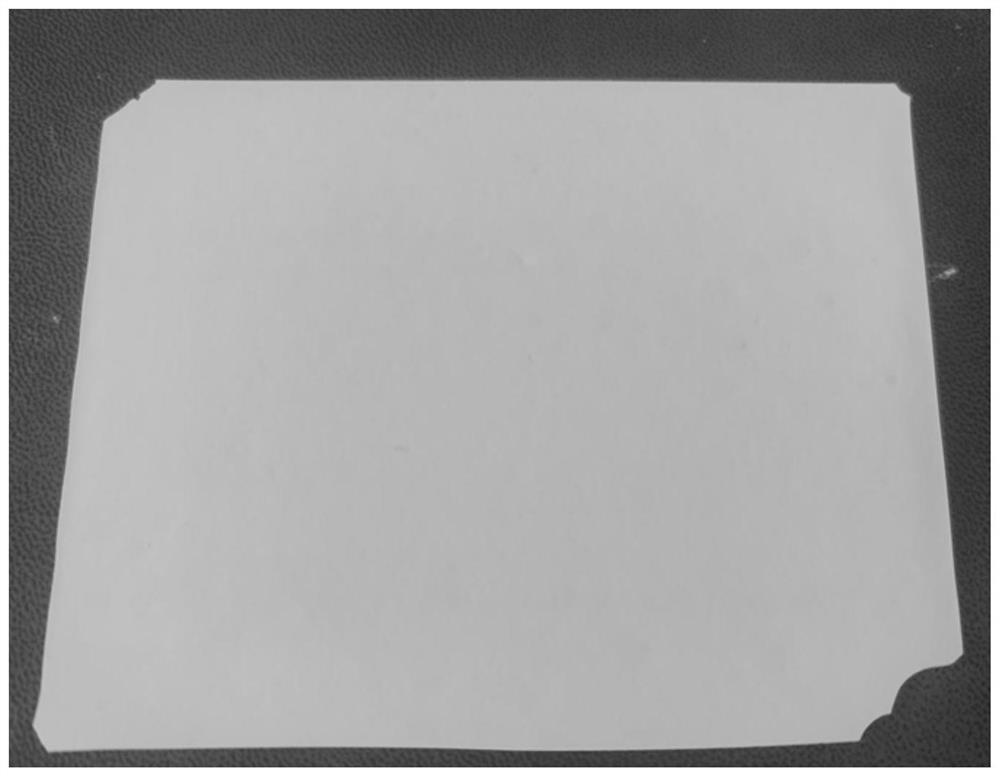

Image

Examples

Embodiment 1

[0024] The sintering process of the tape-casting alumina sheet provided by the present embodiment, the specific technical scheme is as follows:

[0025] Cut the tape-cast alumina body with a thickness of 0.15mm into square pieces of 80mm*80mm and place it on the alumina sheet to ensure that there are no dust particles on the surface of the board and the body, and then cover it with a layer of alumina sheet . The covered alumina body is dried, plastic-removed, strength-increased and sintered according to the following temperature setting requirements.

[0026] The specific temperature parameters are as follows:

[0027] Drying treatment: room temperature -80℃, keep warm for 1 hour; 80-160℃, keep warm for 2 hours; 160-200℃, keep warm for 3 hours; 200-240℃, keep warm for 5 hours; 240-260℃, keep warm for 6 hours; 260 ℃ naturally cooled to room temperature. The drying is divided into two stages. The first stage is room temperature -80°C, which is kept for 1 hour; 80-160°C, which...

Embodiment 2

[0033] The sintering process of the tape-casting alumina sheet provided by the present embodiment, the specific technical scheme is as follows:

[0034] Cut the aluminum oxide embryo body with a thickness of 0.15mm after tape casting into a square piece of 80mm*80mm and place it on the corundum mullite board to ensure that there are no dust particles on the surface of the board and the embryo body, and then cover it with a layer of corundum mullite. Come to slate. The covered alumina body is dried, plastic-removed, strength-increased and sintered according to the following temperature setting requirements.

[0035] The specific temperature parameters are as follows:

[0036] Drying treatment: room temperature -80℃, keep warm for 1 hour; 80-160℃, keep warm for 2 hours; 160-200℃, keep warm for 3 hours; 200-240℃, keep warm for 5 hours; 240-260℃, keep warm for 6 hours; 260 ℃ naturally cooled to room temperature. The drying is divided into two stages. The first stage is room tem...

Embodiment 3

[0042]The sintering process of the tape-casting alumina sheet provided by the present embodiment, the specific technical scheme is as follows:

[0043] Cut the aluminum oxide embryo body with a thickness of 0.15mm after tape casting into a square piece of 80mm*80mm and place it on the corundum mullite board to ensure that there are no dust particles on the surface of the board and the embryo body, and then cover it with a layer of corundum mullite. Come to slate. The covered alumina body is dried, plastic-removed, and sintered according to the following temperature setting requirements.

[0044] The specific temperature parameters are as follows:

[0045] Drying treatment: room temperature -80℃, keep warm for 1 hour; 80-160℃, keep warm for 2 hours; 160-200℃, keep warm for 3 hours; 200-240℃, keep warm for 5 hours; 240-260℃, keep warm for 6 hours; 260 ℃ naturally cooled to room temperature.

[0046] Plastic removal treatment: room temperature -260 °C, heating for 3 hours; 260...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com