Mixed alcohol polyether with low surface tension and preparation method thereof

A low surface tension, mixed alcohol technology, applied in the field of organic compound synthesis, can solve the problems of low molecular distribution, low surface tension, uneven dispersion, etc., and achieve the effect of increased hydrogen bonding, strong directionality and saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment provides a low surface tension mixed alcohol polyether and a preparation method thereof, and the specific steps are as follows:

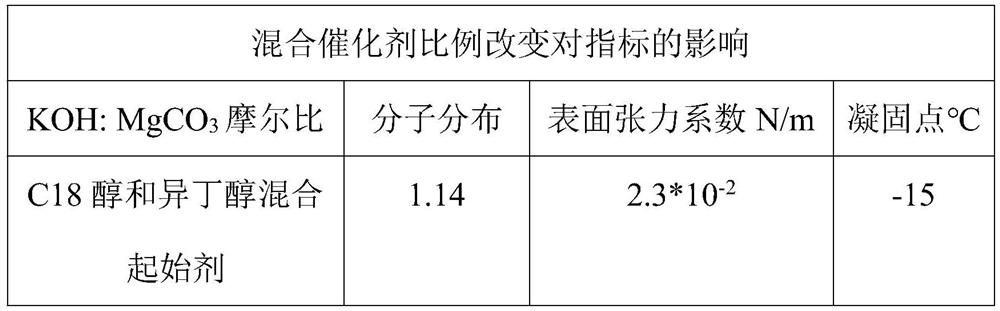

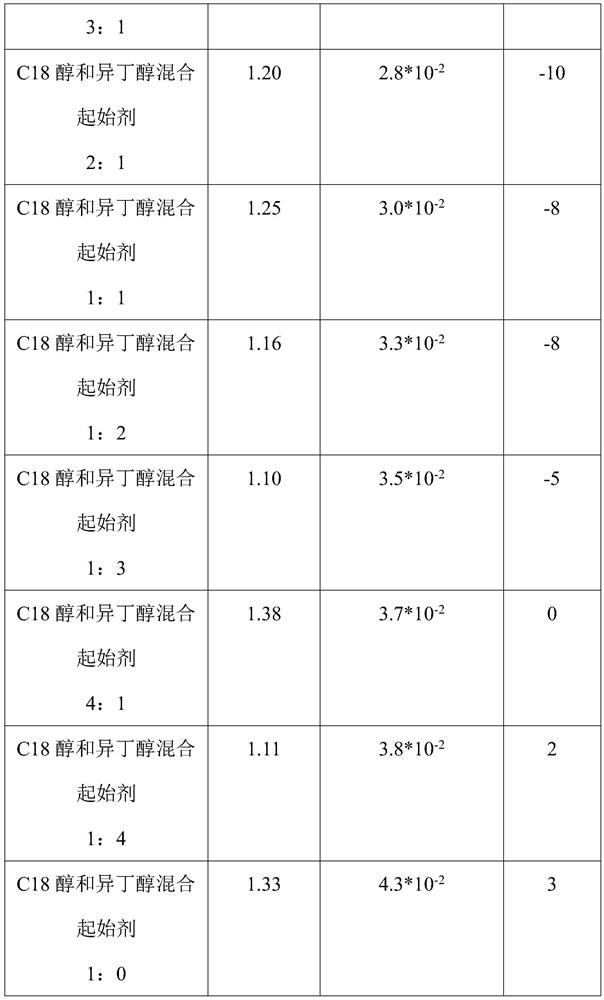

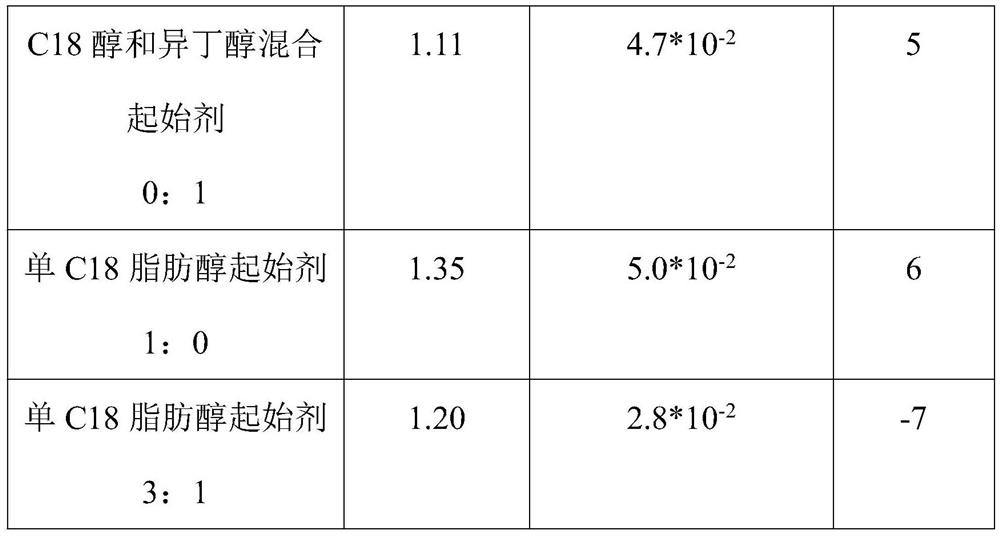

[0024] 1.27g KOH and 0.63g MgCO in a molar ratio of 3:1 3 After mixing evenly, grind to powder to prepare mixed catalyst;

[0025] 189.3g C18 aliphatic alcohol and 22.2g isobutanol, 1.90g mixed catalyst are put into the 2.5L reaction kettle, and the N in the replacement kettle is replaced. 2 3 times, after dehydration at 100℃-105℃ for 1 hour under vacuum degree ≥0.095℃, the temperature is raised to 115℃, 1334g propylene oxide is slowly added, the dropping speed is uniform, and the reaction temperature is controlled at 115℃-120℃ for reaction, wait for After all the dropwise addition of the propylene oxide is completed, the aging is carried out until the pressure in the kettle is basically unchanged;

[0026] After cooling to 100°C, remove the gas in the kettle to a degree of vacuum ≥ 0.095Mpa; continue to heat up to 14...

Embodiment 2

[0029] The present embodiment provides a low surface tension mixed alcohol polyether and a preparation method thereof, and the specific steps are as follows:

[0030] 1.09g KOH and 0.81g MgCO in a molar ratio of 2:1 3 After mixing evenly, grind to powder to prepare mixed catalyst;

[0031] 189.3g C18 aliphatic alcohol and 22.2g isobutanol, 1.90g mixed catalyst are put into the 2.5L reaction kettle, and the N in the replacement kettle is replaced. 2 3 times, after dehydration at 100℃-105℃ for 1 hour under vacuum degree ≥0.095℃, the temperature is raised to 115℃, 1334g propylene oxide is slowly added, the dropping speed is uniform, and the reaction temperature is controlled at 115℃-120℃ for reaction, wait for After all the dropwise addition of the propylene oxide is completed, the aging is carried out until the pressure in the kettle is basically unchanged;

[0032] After cooling to 100°C, remove the gas in the kettle to a degree of vacuum ≥ 0.095Mpa; continue to heat up to 14...

Embodiment 3

[0035] The present embodiment provides a low surface tension mixed alcohol polyether and a preparation method thereof, and the specific steps are as follows:

[0036] 0.76g KOH and 1.14g MgCO in a molar ratio of 1:1 3 After mixing evenly, grind to powder to prepare mixed catalyst;

[0037] 189.3g C18 aliphatic alcohol and 22.2g isobutanol, 1.90g mixed catalyst are put into the 2.5L reaction kettle, and the N in the replacement kettle is replaced. 2 3 times, after dehydration at 100℃-105℃ for 1 hour under vacuum degree ≥0.095℃, the temperature is raised to 115℃, 1334g propylene oxide is slowly added, the dropping speed is uniform, and the reaction temperature is controlled at 115℃-120℃ for reaction, wait for After all the dropwise addition of the propylene oxide is completed, the aging is carried out until the pressure in the kettle is basically unchanged;

[0038] After cooling to 100°C, remove the gas in the kettle to a degree of vacuum ≥ 0.095Mpa; continue to heat up to 14...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension coefficient | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

| Freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com