Spiral sorting machine structure optimization method based on FLUENT-EDEM coupling simulation

A technology of FLUENT-EDEM and spiral sorting machine, applied in design optimization/simulation, geometric CAD, computer-aided design, etc., can solve problems such as low calculation accuracy, weak feasibility, difficult simulation, etc., and achieve good sorting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below with reference to specific embodiments and accompanying drawings.

[0023] 1. Data collection

[0024] According to the total solid feeding amount of the pulp required to be sorted, the solid weight concentration, the water amount, the solid relative density (the average value does not contain voids), the solid volume per unit time (without voids) and the pulp volume per unit time (water density according to 1t / h), the feeding outlet pipe diameter, so as to calculate the outlet flow rate (the initial velocity of the slurry entering the screw).

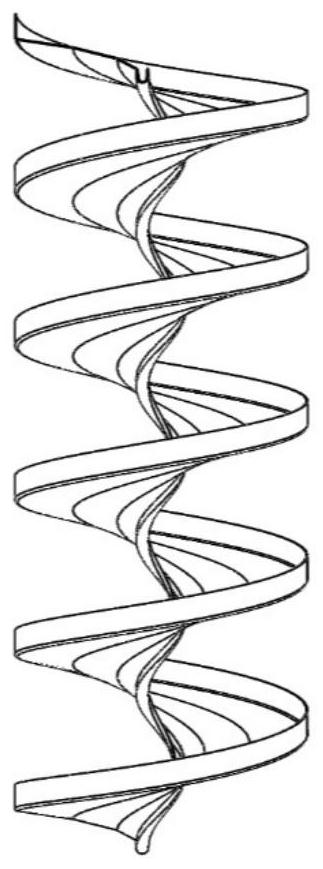

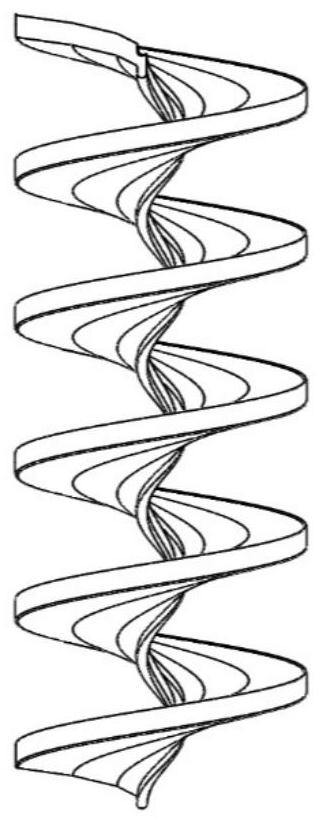

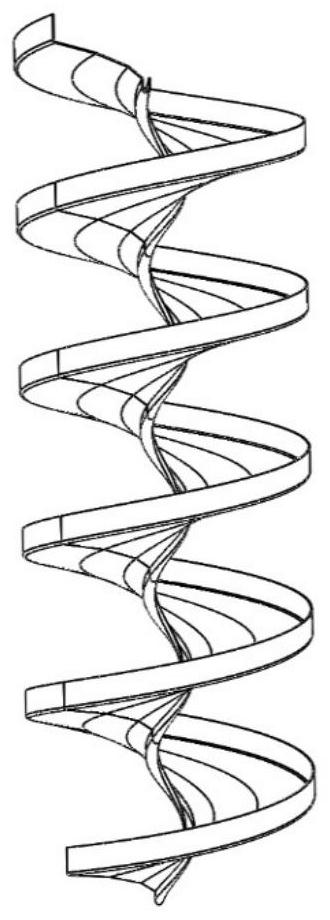

[0025] This experiment is based on Fluent software and EDEM software. The basic parameters of the spiral sorting machine model used in this case include: the inner diameter, outer diameter, starting angle, number of rotations, and height of the spiral groove, which are in the order of 10 to the power of 3 in mm, and export the file in IGS format. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com