Magnetic core-shell structure porous silicon dioxide carrier for laccase immobilization as well as preparation method and application of magnetic core-shell structure porous silicon dioxide carrier

A technology of porous silica and core-shell structure, applied in the directions of silica, silica, etc., which are fixed on or in an inorganic carrier, can solve the problems of inability to achieve repeated use, poor long-term preservation, and easy shedding of enzymes, etc. Achieving the effect of wide pH and temperature applicable range, excellent performance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

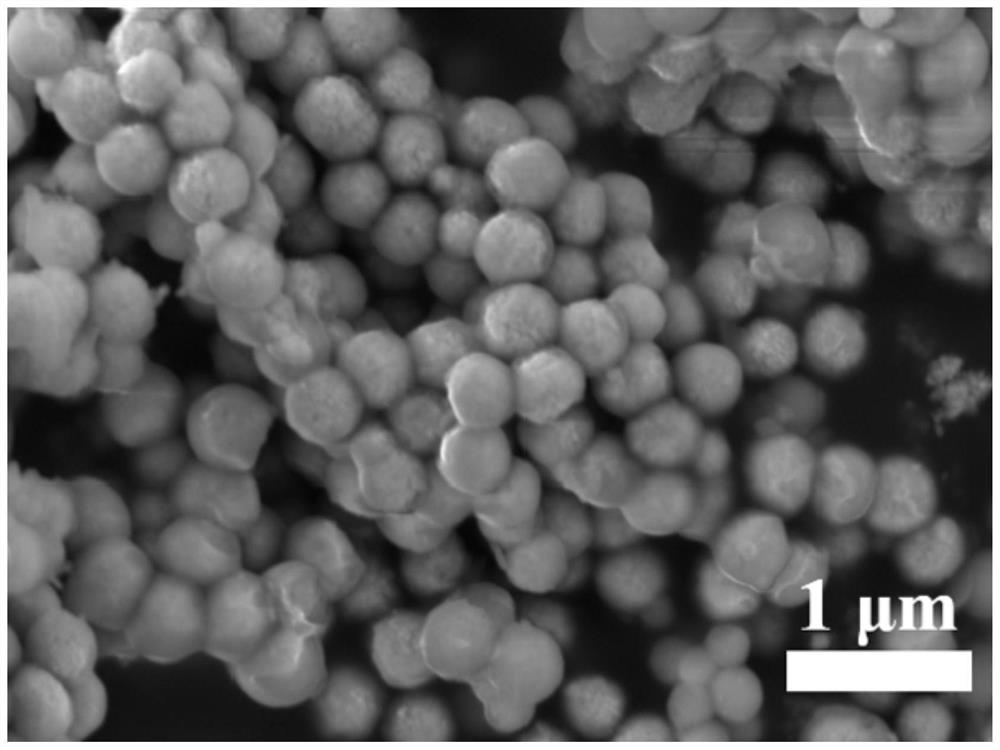

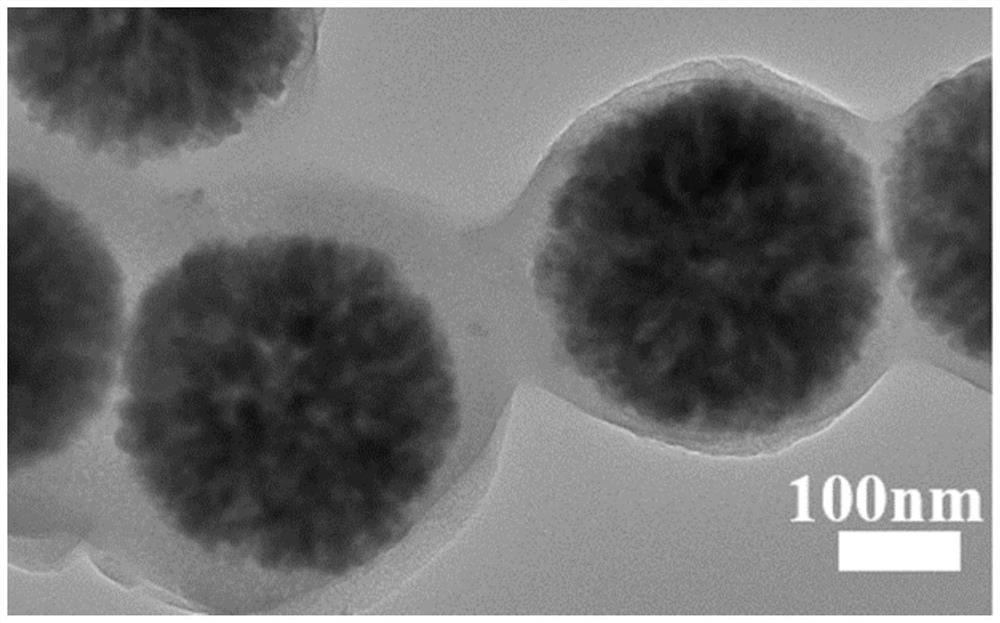

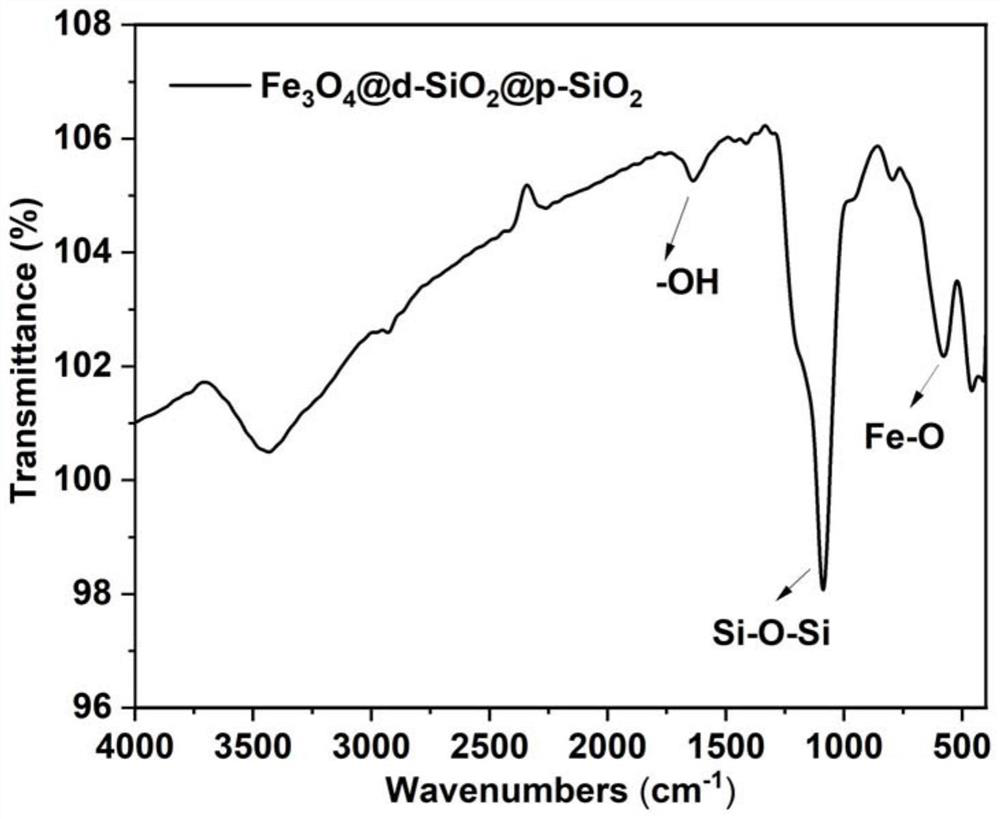

[0040] A preparation method of magnetic silica microspheres with core-shell structure, the method comprises the following steps:

[0041] (1) The magnetic Fe 3 O 4 Disperse in a mixed solution consisting of ethanol, deionized water and concentrated ammonia, and ultrasonicate for 30 min to obtain a suspension. TEOS was then added dropwise to the suspension and stirring was continued for 6 h in a 30°C water bath. After the reaction, the product was separated with a magnet, washed and dried to obtain Fe 3 O 4 @d-SiO 2 . TEOS and Fe 3 O 4 The mass ratio of (0.1-0.3) g: (0.05-0.15) g.

[0042] (2) Fe 3 O 4 @d-SiO 2 Disperse in a mixed solution containing CTAB, ethanol, deionized water and concentrated ammonia, and stir for 30 min to form a homogeneous solution. Under continuous stirring, TEOS was added dropwise to the above solution and stirred continuously for 6 h in a 30 °C water bath. After the reaction, the product was separated with a magnet and washed several tim...

Embodiment 1

[0047] A preparation method of a magnetic core-shell structure porous silica carrier, the method comprises the following steps:

[0048] (1) 0.1g of magnetic Fe 3 O 4 Dispersed in a mixed solution consisting of 120 mL of ethanol, 40 mL of deionized water and 4 mL of concentrated ammonia water, and ultrasonicated for 30 min to obtain a suspension. Then 0.2 g of TEOS was added dropwise to the suspension, and stirring was continued for 6 h in a 30° C. water bath. After the reaction, the product was separated with a magnet, washed and dried to obtain Fe 3 O 4 @d-SiO 2 .

[0049] (2) 0.15g Fe 3 O 4 @d-SiO 2 Disperse in a mixed solution containing 0.3 g CTAB, 60 mL ethanol, 80 mL deionized water and 1 mL concentrated ammonia water, and stir for 30 min to form a homogeneous solution. Under continuous stirring, 0.4 g of TEOS was added dropwise to the above solution, and stirred continuously for 6 h in a water bath at 30 °C. After the reaction, the product was separated with ...

Embodiment 2

[0057] A preparation method of a magnetic core-shell structure porous silica carrier, the method comprises the following steps:

[0058] (1) 0.05g magnetic Fe 3 O 4 Dispersed in a mixed solution consisting of 120 mL of ethanol, 40 mL of deionized water and 4 mL of concentrated ammonia water, and ultrasonicated for 30 min to obtain a suspension. Then 0.1 g of TEOS was added dropwise to the suspension, and stirring was continued for 6 h in a 30°C water bath. After the reaction, the product was separated with a magnet, washed and dried to obtain Fe 3 O 4 @d-SiO 2 .

[0059] (2) 0.1g Fe 3 O 4 @d-SiO 2 Disperse in a mixed solution containing 0.3 g CTAB, 60 mL ethanol, 80 mL deionized water and 1 mL concentrated ammonia water, and stir for 30 min to form a homogeneous solution. Under continuous stirring, 0.3 g of TEOS was added dropwise to the above solution, and stirred continuously for 6 h in a 30 °C water bath. After the reaction, the product was separated with a magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com