Process system and process method for increasing yield of p-xylene

A p-xylene and process system technology, applied in chemical instruments and methods, chemical industry, bulk chemical production, etc., can solve the problems of waste clay pollution, frequent replacement, etc., to solve frequent replacement, improve conversion rate, reduce The effect of device energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

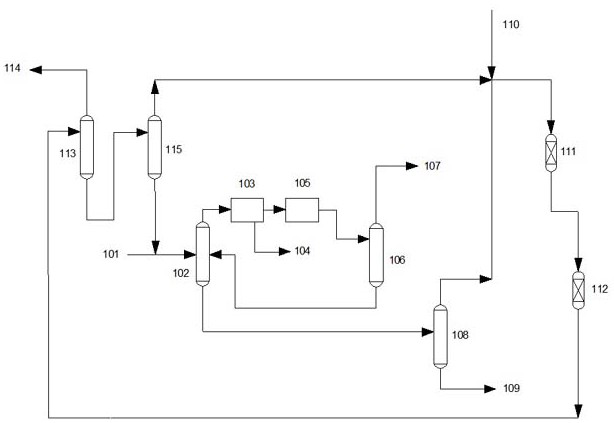

Image

Examples

Embodiment 1

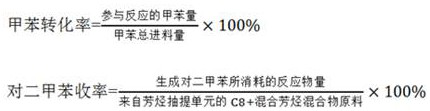

[0053] Example 1 illustrates the production increase process and energy consumption for the production of p-xylene provided by the present invention. The feed composition was consistent with Comparative Example 1, with >95% purity of benzene and toluene from the aromatics extraction unit.

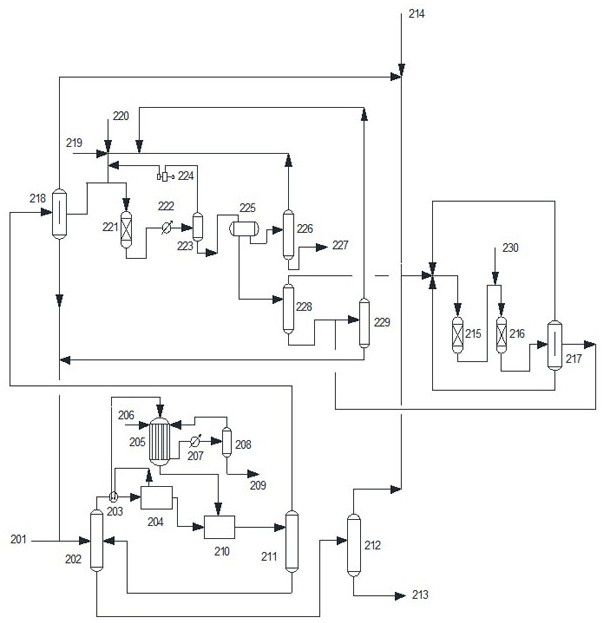

[0054] use figure 2 The process system shown is for the production of p-xylene. The results show that the conversion of toluene is 27.2%, the yield of p-xylene is 67.2%, and the energy consumption of the device is 285kgEO / (t•PX).

[0055] Compared with Comparative Example 1, the process system and process method for prolific paraxylene provided by the present invention are compared with conventional xylene production processes, the toluene conversion rate is increased by 28.1%, the paraxylene yield is increased by 10.2%, and the energy consumption of the device is increased. decreased by 11.1%. The invention solves the problem of large circulation volume of disproportionation and transal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com