Application of polyimide in gas separation membrane

A technology of gas separation membrane and polyimide, which is applied in separation methods, semi-permeable membrane separation, dispersed particle separation, etc., can solve the problems of separation selectivity and gas permeability that cannot be improved at the same time, and achieve good mechanical properties and thermal properties. Stability, good solubility, and the effect of increasing free volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

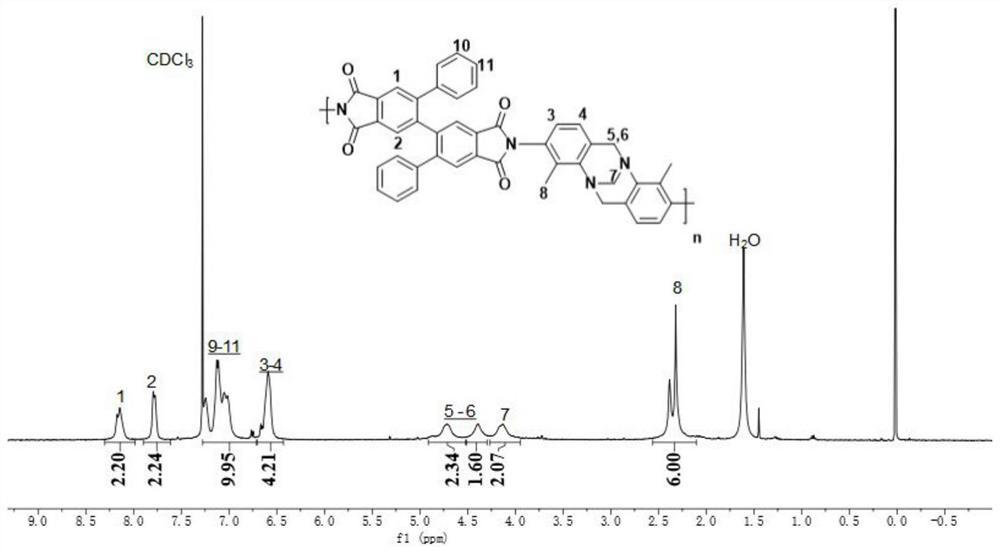

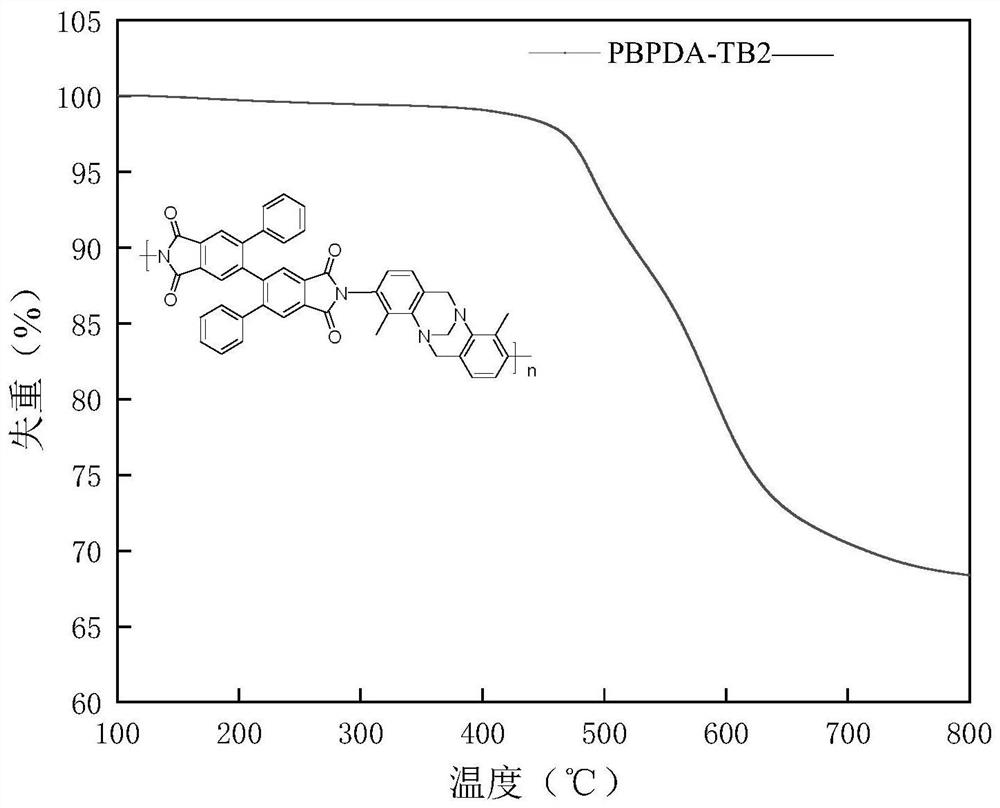

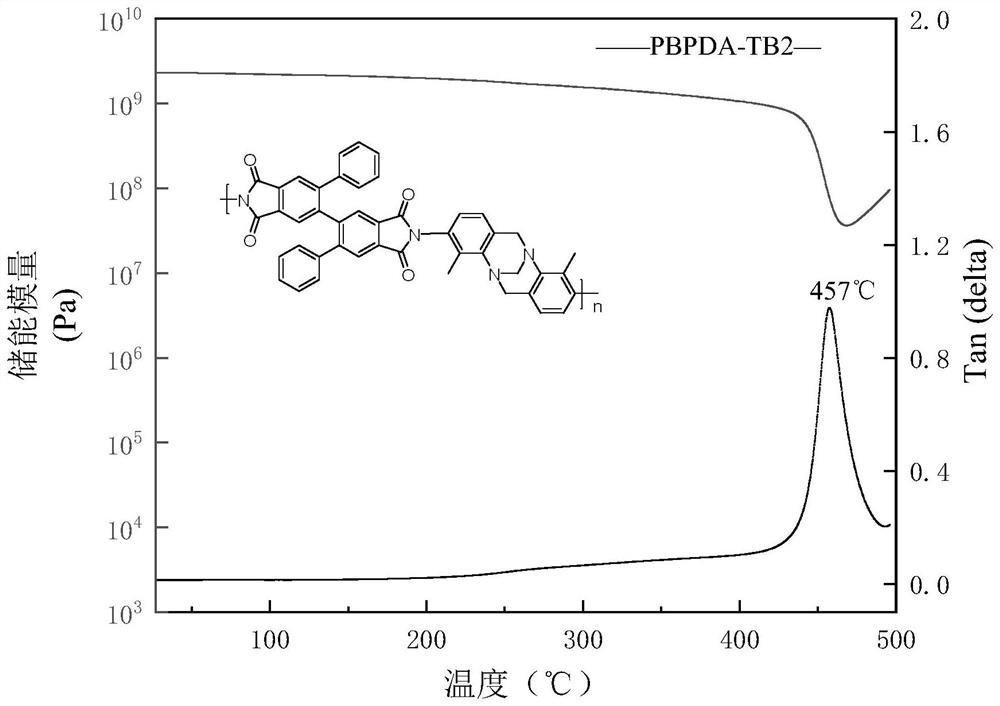

[0046] In this embodiment, the polyimide has the structure of the following formula:

[0047]

[0048]The preparation of polyimide gas separation membrane mainly includes the following steps:

[0049] Under the protection of nitrogen atmosphere, 0.5841g (1.3mmol) of 2,2'-diphenyl-4,4',5,5'biphtalic dianhydride and 0.3668 (1.3mmol) of 3,9-diamino -4,10-Dimethyl-6H,12H-5,11-methyldiphenyl[b,f][1,5]diazacine and 0.0855g (0.65mmol) benzoic acid were placed in a three-neck polymerization flask , then add 3.80g of anhydrous m-cresol to make the solid content of the whole system 20wt%, adjust the mechanical stirring to about 200r / min, heat the system to 80 °C and stir for 2h to make it completely dissolved, forming a relatively transparent Light yellow solution, after the solid is completely dissolved, the system is heated to 180 ° C for thermal imidization, the reaction is about 10h to complete thermal imidization of polyimide, and 4.76g of m-cresol is added to reduce the solid ...

Embodiment 2

[0053] In this embodiment, the polyimide has the structure of the following formula;

[0054]

[0055] The preparation of polyimide gas separation membrane mainly includes the following steps:

[0056] Under the protection of nitrogen atmosphere, 1.5049g (2.58mmol) of 2,2'-bis(2"-trifluoromethylphenyl)-4,4',5,5'biphtalic dianhydride and 0.7253g (2.58mmol) 3,9-diamino-4,10-dimethyl-6H,12H-5,11-methyldiphenyl[b,f][1,5]diazacine and 0.1578g (1.29 mmol) benzoic acid in a three-necked polymerization bottle, then add 8.92 g of anhydrous m-cresol to make the solid content of the entire system 20 wt%, adjust the mechanical stirring to about 200 r / min, and heat the system to 80 ° C and stir for 2 h It was completely dissolved to form a relatively transparent pale yellow solution. After the solid was completely dissolved, the system was heated to 180 ° C for thermal imidization, and the polyimide was reacted for about 10 h to complete thermal imidization, and then 13.63 g of m-forma...

Embodiment 3

[0060] In this embodiment, the polyimide has the structure of the following formula;

[0061]

[0062] The preparation of polyimide gas separation membrane mainly includes the following steps:

[0063] Under the protection of nitrogen atmosphere, 0.8074g (1.12mmol) 3,3"',5,5"'-tetrafluoromethyl-[1,1':2',1":2",1"' -Tetraphenyl]-4,4',5,5'-tetracarboxylic dianhydride and 0.2807g (1.12mmol) 3,9-diamino-4,10-dimethyl-6H,12H-5,11- Methyldiphenyl[b,f][1,5]diazacine and 0.0850g (0.56mmol) benzoic acid were placed in a three-neck polymerization bottle, and then 4.49g anhydrous m-cresol was added to make the solid content of the whole system is 20 wt%, adjust the mechanical stirring to about 200 r / min, heat the system to 80 °C and stir for 2 h to make it completely dissolved, forming a relatively transparent pale yellow solution, after the solid is completely dissolved, the system is heated to 180 °C for thermal sublimation. Amination, the polyimide was completely thermally imidize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com