Nano cellulose as well as preparation method and application thereof

A technology of nanocellulose and cellulose, applied in the field of enzyme engineering, can solve the problem that nanocellulose does not have functional groups, and achieve the effects of low cost, wide application prospects and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

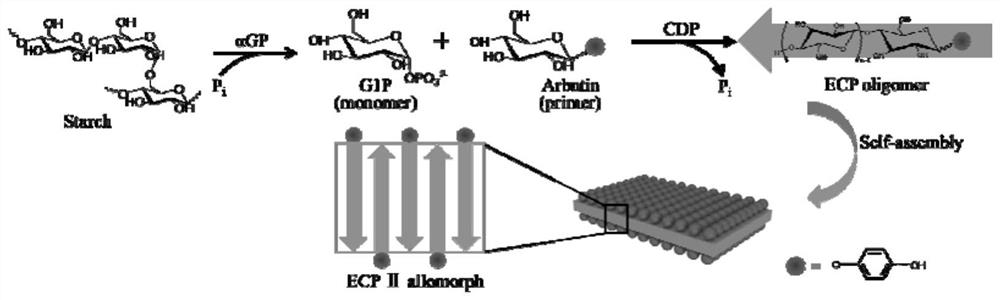

[0037] like figure 2 As shown, a preparation method of nanocellulose, the specific steps are as follows:

[0038] (1) In the whole reaction system, add 50g / L soluble starch, 10mM arbutin primer, 20mM inorganic phosphorus (by KH 2 PO 4 and K 2 HPO 4 prepared), 10mM magnesium ion, 2g / LαGP (amino acid sequence NCBI accession number is WP_011250357.1) and 2g / L CDP (amino acid sequence NCBI accession number is WP_020457986.1), 200mM HEPES (pH7.5) buffer solution , put the whole system at 45°C in a water bath to synthesize nanocellulose;

[0039] (2) The nanocellulose obtained in step (1) was washed, centrifuged and purified 10 times with HEPES solution (same as in step (1)), and then freeze-dried.

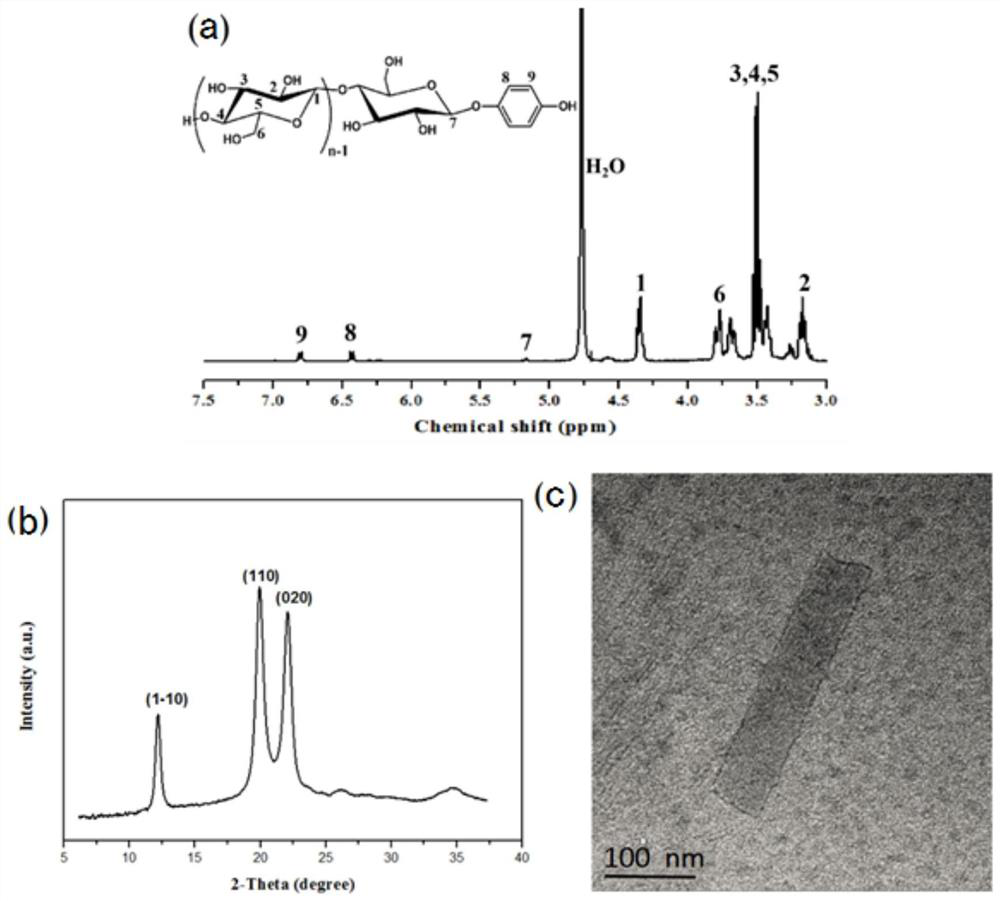

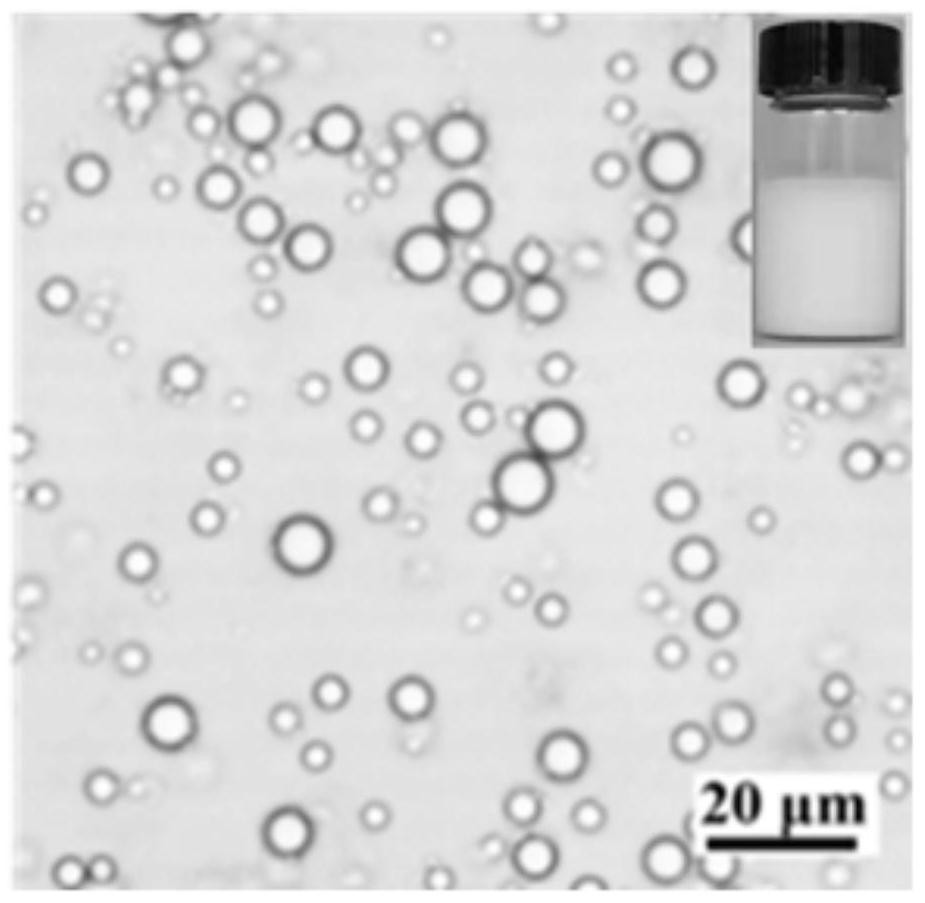

[0040] The characterization of the novel nanocellulose synthesized by the enzyme-catalyzed method in the examples is as follows: figure 1 shown. Figure (a) shows the new nanocellulose 1 H NMR data. 4.35ppm is expressed as the 1-position hydrogen (H) in the glucose structural u...

Embodiment 2

[0044] A preparation method of nanocellulose, the specific steps are as follows:

[0045] (1) In the whole reaction system, add 100g / L soluble amylose, 50mM arbutin primer, 40mM inorganic phosphorus (by NaH 2 PO 4 and Na 2 HPO 4 prepared), 10mM magnesium ion, 5g / LαGP and 2g / L CDP, 600mM HEPES (pH7.5) buffer solution, put the whole system at 40°C in a water bath to synthesize nanocellulose;

[0046] (2) The nanocellulose obtained in step (1) was washed, centrifuged and purified 10 times with HEPES solution (same as in step (1)), and then freeze-dried.

Embodiment 3

[0048] A preparation method of nanocellulose, the specific steps are as follows:

[0049] (1) In the whole reaction system, add 10g / L soluble starch, 1mM arbutin primer, 1mM inorganic phosphorus (by KH 2 PO 4 prepared), 10mM magnesium ion, 1g / LαGP and 0.1g / L CDP, 10mM HEPES (pH 7.5) buffer solution, the whole system was placed at 45°C in a water bath to synthesize nanocellulose;

[0050] (2) The nanocellulose obtained in step (1) was washed, centrifuged and purified 10 times with HEPES solution (same as in step (1)), and then freeze-dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com