Double-line discharging equipment for high-density integrated circuit lead frame

An integrated circuit and lead frame technology, which is applied in the field of lead frame feeding equipment, can solve the problems of occupying a large area, and achieve the effect of compact and stable structure, not easy to break shaft failure, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be described in detail below with reference to specific embodiments and accompanying drawings.

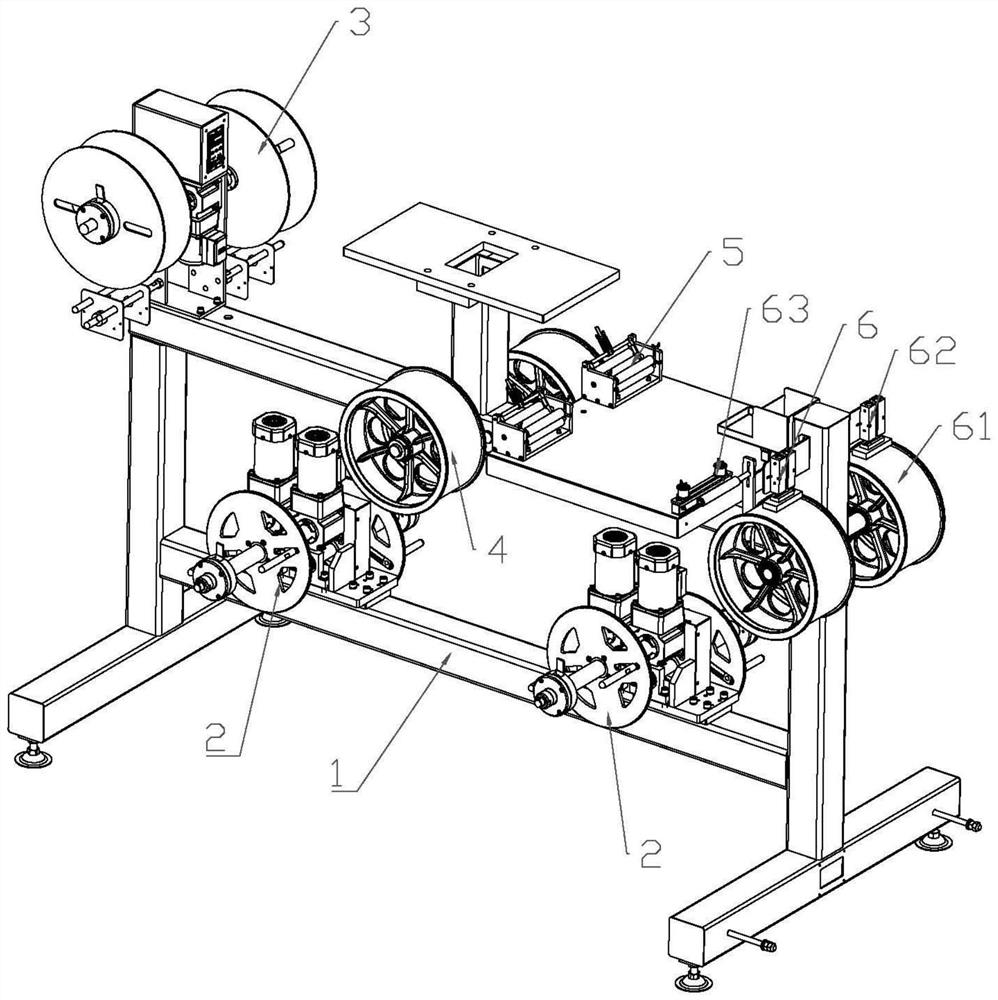

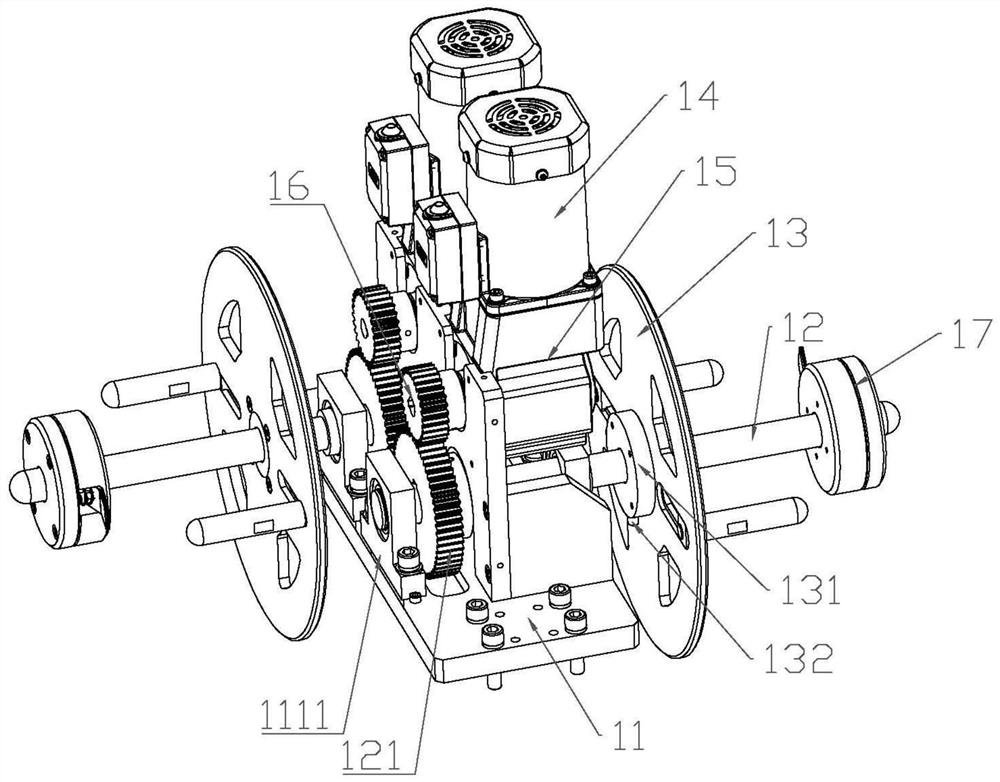

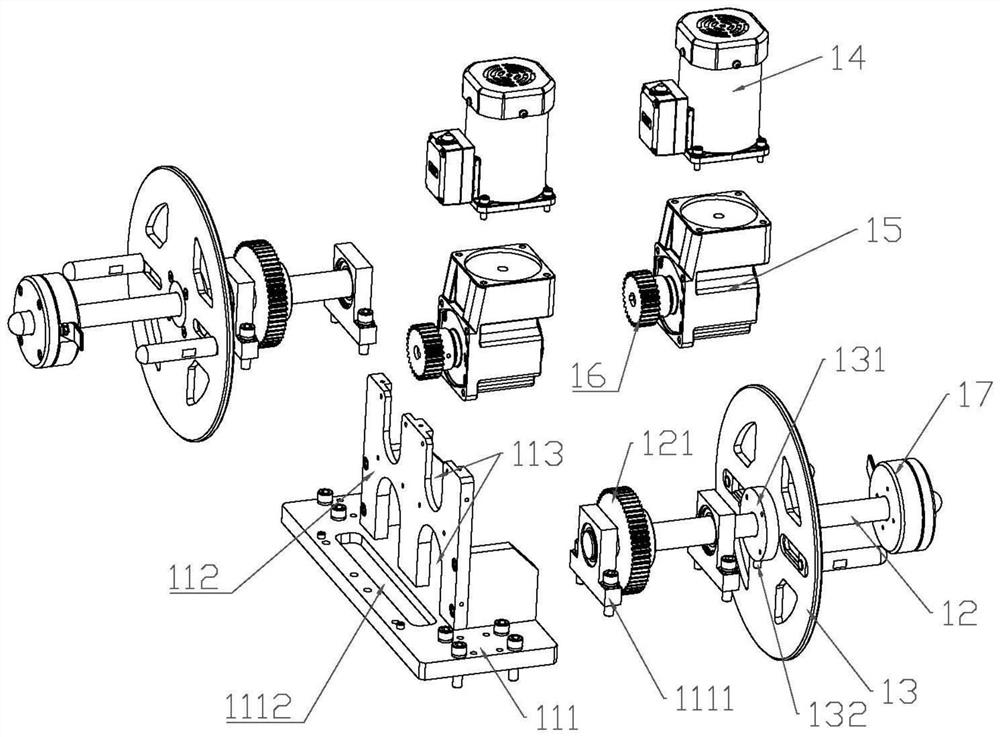

[0058] The high-density integrated circuit lead frame double-wire discharging device of this embodiment, such as figure 1 As shown, it includes a basic frame body 1, an unwinding mechanism 2, a paper delivery mechanism 3 and an end point detection mechanism 5 that can detect the end point of the material tape. One in use and one in standby, after the material belt of one unwinding mechanism 2 is completely released, the material belt of the other unwinding mechanism 2 is used immediately, and there is no need to wait for a long time to change the shaft. The upper layer of the basic frame body 1 is distributed with a delivery mechanism 3 , a middle guide wheel 4 , an end detection mechanism 5 and a material belt clamping mechanism 6 . When in use, the unwinding mechanism 2 is inserted into the reel with the lead frame tape, and the unwinding mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com