High-strength self-healing hydrogel and preparation method thereof

A hydrogel, high-strength technology, applied in the field of materials, can solve the problems of complicated equipment and instruments, difficult operation, multiple raw materials, etc., and achieve the effects of increasing the healing rate, increasing the hydrogen bond density, and increasing the hydrogen bond density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

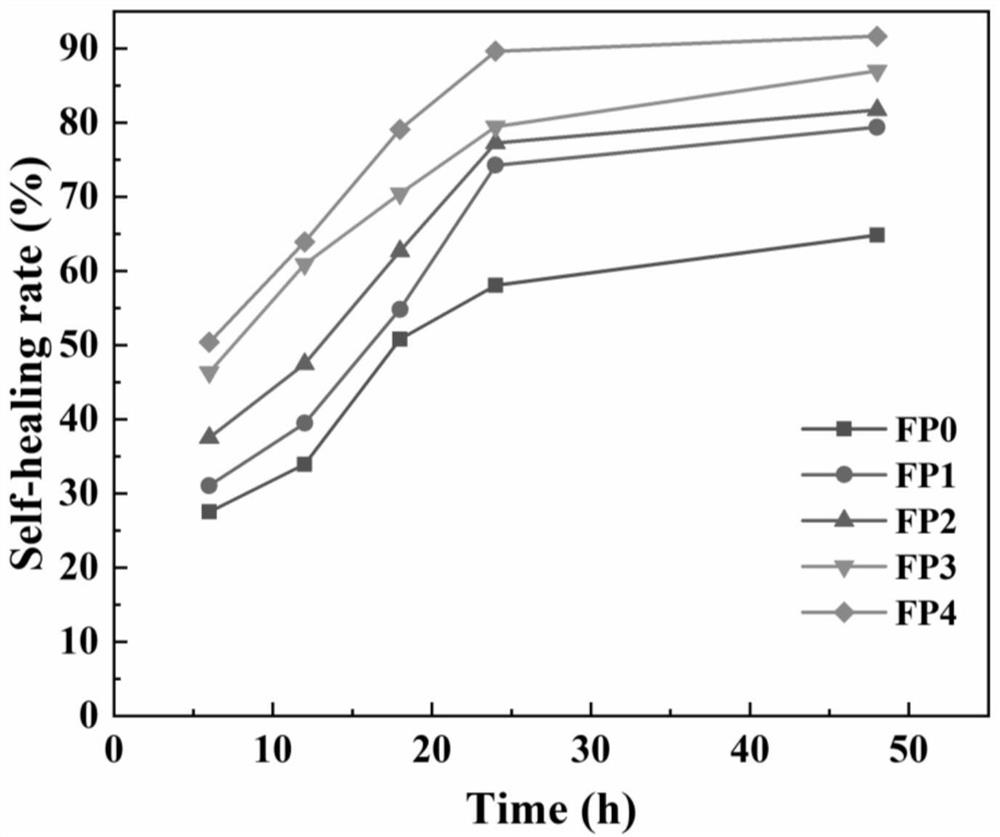

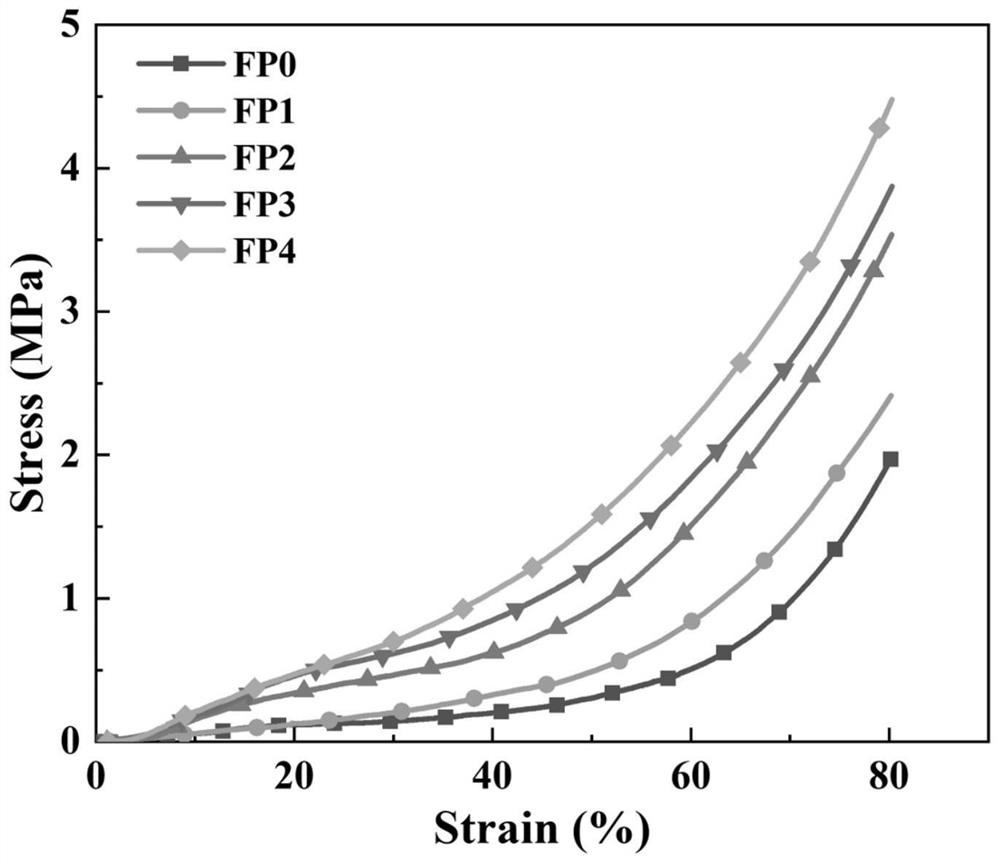

[0047] Example 1 (FP1):

[0048] (1) Mix 2.132g of acrylamide, 4.189g of choline chloride, 2.162g of acrylic acid, and 0.085g of N,N-methylenebisacrylamide, stir in an oil bath at 70°C until a transparent and clear liquid is formed, and let stand Cool to room temperature to obtain room temperature deep eutectic solvent liquid;

[0049] (2) 0.043g potassium persulfate and 0.022g β-cyclodextrin were successively added to the room temperature deep eutectic solvent liquid obtained in step (1) to form a mixture solution, and then the formed mixture solution was transferred into a test tube, using electric The soldering iron is heated at the upper end of the reactor, so that the initiator is decomposed by heat to initiate the reaction. After the thermal initiation reaction begins, the heat source is withdrawn until all the raw materials in the entire reactor are converted into polymer gel;

[0050] (3) soaking and washing the polymer gel obtained in step (2) with distilled water to...

Embodiment 2

[0052] Example 2 (FP2):

[0053] (1) Mix 2.132g of acrylamide, 4.189g of choline chloride, 2.162g of acrylic acid, and 0.085g of N,N-methylenebisacrylamide, stir in an oil bath at 70°C until a transparent and clear liquid is formed, and let stand Cool to room temperature to obtain room temperature deep eutectic solvent liquid;

[0054] (2) 0.043g potassium persulfate and 0.043g β-cyclodextrin were successively added to the room temperature deep eutectic solvent liquid obtained in step (1) to form a mixture solution, and then the formed mixture solution was transferred into a test tube, using electric The soldering iron is heated at the upper end of the reactor, so that the initiator is decomposed by heat to initiate the reaction. After the thermal initiation reaction begins, the heat source is withdrawn until all the raw materials in the entire reactor are converted into polymer gel;

[0055] (3) soaking and washing the polymer gel obtained in step (2) with distilled water to...

Embodiment 3

[0057] Example 3 (FP3):

[0058] (1) Mix 2.132g of acrylamide, 4.189g of choline chloride, 2.162g of acrylic acid, and 0.085g of N,N-methylenebisacrylamide, stir in an oil bath at 70°C until a transparent and clear liquid is formed, and let stand Cool to room temperature to obtain room temperature deep eutectic solvent liquid;

[0059] (2) 0.043g potassium persulfate and 0.087g β-cyclodextrin were successively added to the room temperature deep eutectic solvent liquid obtained in step (1) to form a mixture solution, and then the formed mixture solution was transferred into a test tube, using an electric The soldering iron is heated at the upper end of the reactor, so that the initiator is decomposed by heat to initiate the reaction. After the thermal initiation reaction begins, the heat source is withdrawn until all the raw materials in the entire reactor are converted into polymer gel;

[0060] (3) soaking and washing the polymer gel obtained in step (2) with distilled water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com