A kind of self-healing powder coating based on polyurethane resin and preparation method thereof

A polyurethane resin and powder coating technology, which is applied in polyurea/polyurethane coatings, powder coatings, anti-corrosion coatings, etc., can solve the problems of reduced repair effect and low crosslinking degree of cured coating film, so as to improve heat resistance and coating The effect of easy cleaning and excellent self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

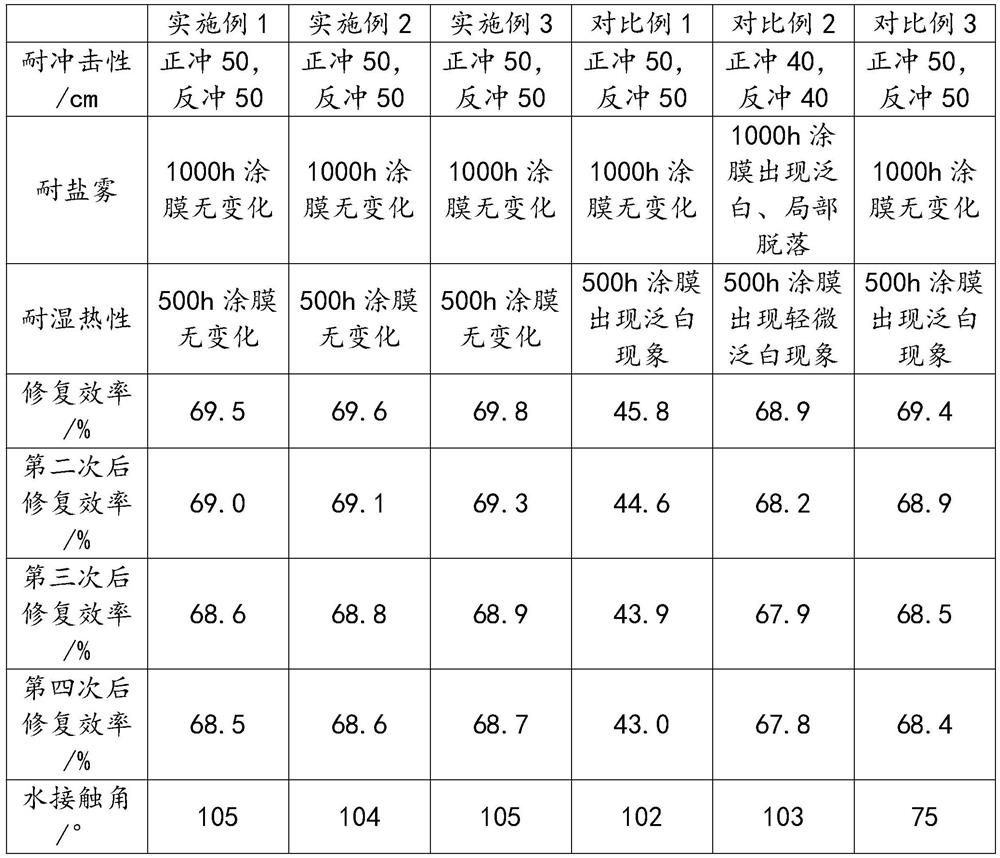

Examples

preparation example Construction

[0036] The preparation method of the powder coating comprises the following steps:

[0037] The first step is to weigh each raw material according to the parts by weight and add it to the mixing tank, and stir for 4-6min under the condition of rotating speed 400r / min;

[0038] In the second step, the mixture is poured into a twin-screw extruder, melt extruded, and the heating conditions of the extruder are 110°C in zone I and 125°C in zone II;

[0039] The third step, after the extrusion is completed, cool down to room temperature, and send it to the pulverizer for grinding. The grinding conditions are 8500-9500r / min for the main mill and 6500-7500r / min for the auxiliary mill, and pass through a 180-mesh sieve to obtain powder. coating.

Embodiment 1

[0041] A self-healing powder coating based on polyurethane resin is prepared from the following raw materials in parts by weight: 50 parts of modified polyurethane resin, 6 parts of silicon-modified hydroxy acrylic resin, 10 parts of curing agent, 1 part of leveling agent, and 0.5 part of brightener , 0.2 parts of curing accelerator, 20 parts of composite filler;

[0042] The powder coating is made by the following steps:

[0043] The first step is to weigh each raw material according to the parts by weight and add it to the mixing tank, and stir for 4min under the condition of a rotating speed of 400r / min;

[0044] In the second step, the mixture is poured into a twin-screw extruder, melt extruded, and the heating conditions of the extruder are 110°C in zone I and 125°C in zone II;

[0045] The third step, after the extrusion is completed, cool to normal temperature, send it to the pulverizer for grinding, and the grinding conditions are 8500r / min for the main mill and 6500r...

Embodiment 2

[0047] A self-healing powder coating based on polyurethane resin is prepared from the following raw materials in parts by weight: 55 parts of modified polyurethane resin, 7 parts of silicon-modified hydroxy acrylic resin, 12 parts of curing agent, 1.2 parts of leveling agent, and 0.55 parts of brightener , 0.25 parts of curing accelerator, 23 parts of composite filler;

[0048] The powder coating is made by the following steps:

[0049] The first step is to weigh each raw material according to the parts by weight and add it to the mixing tank, and stir for 5min under the condition of rotating speed 400r / min;

[0050] In the second step, the mixture is poured into a twin-screw extruder, melt extruded, and the heating conditions of the extruder are 110°C in zone I and 125°C in zone II;

[0051] The third step, after the extrusion is completed, cool to room temperature, send it to the pulverizer for grinding, and the grinding conditions are 9000r / min for the main mill and 7000r / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com