Manufacturing equipment and process for surface-mounted packaged laser diode

A technology of laser diode and chip packaging, which is applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve problems such as inability to complete automatic loading and unloading, manufacturing and angle adjustment, equipment failure, and electrical components failure, etc., to achieve Convenient angle adjustment, less manual intervention, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

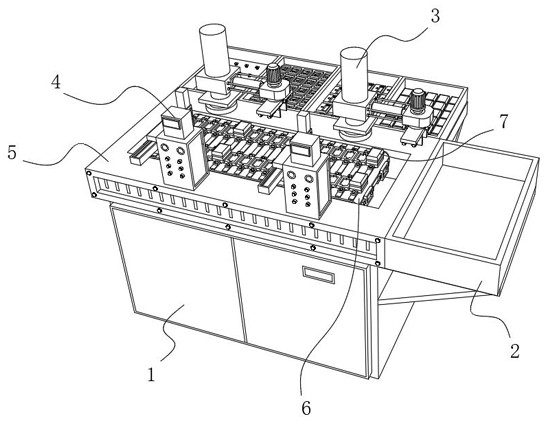

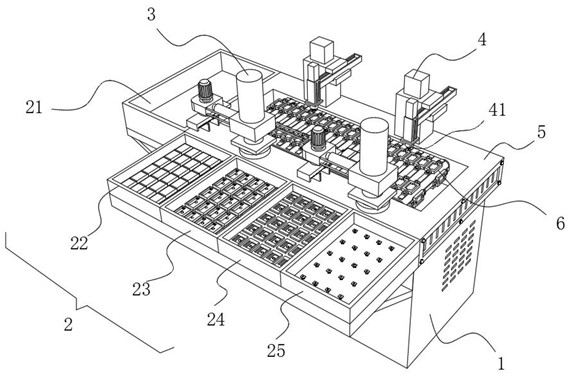

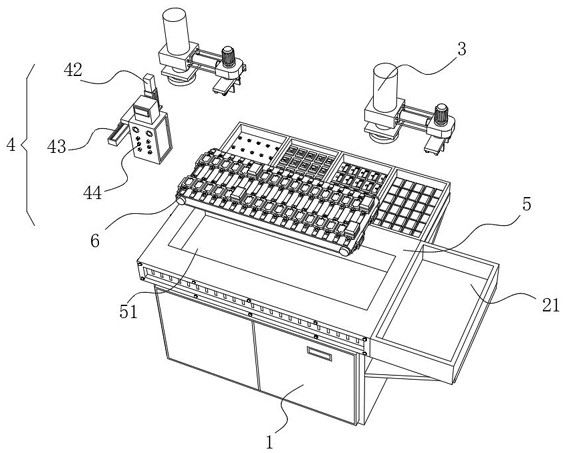

[0050] see Figure 1 to Figure 10 , the present invention provides a kind of technical scheme:

[0051] A chip-packaged laser diode manufacturing equipment, comprising an electrical equipment workbench 5 and an electrical equipment parts main body 7, the top middle of the electrical equipment workbench 5 is provided with an electrical equipment parts conveying assembly 6 for conveying electronic components, and the electrical equipment The top of the worktable 5 is located on one side of the electrical equipment parts conveying assembly 6 and is provided with at least one electrical equipment parts welding machine 4, and the top of the electrical equipment worktable 5 is located on the other side of the electrical equipment parts conveying assembly 6 with at least one electrical equipment parts welding machine 4. An electrical equipment component manufacturing assembly 3 for moving electronic components, the side wall of the electrical equipment workbench 5 close to the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com