Artificial stone and preparation method thereof

A technology of artificial stone and raw materials, which is applied in the field of artificial stone and its preparation, can solve the problems that artificial stone cannot be self-foamed, cannot be customized to meet application scenarios, and self-filling, etc., and achieves the effects of low cost, simple operation, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A second aspect of the embodiments of the present application provides a method for preparing artificial stone, comprising the following steps:

[0042] S10: Provide the raw material components in the artificial stone of the present application; S20: Mix the raw material components to obtain a slurry;

[0043] S30 The slurry is injected into the mold to perform the first curing treatment, and then the mold is demolded for the second curing treatment to obtain artificial stone.

[0044] In the method for preparing artificial stone provided by the embodiments of the present application, the raw material components are first mixed to obtain a slurry, then the slurry is injected into a mold for a first curing treatment, and a second curing treatment is performed after demoulding to obtain an artificial stone. The preparation process is simple to operate, can self-foam and expand with only one injection, and can be self-filled and formed without vibrating. Therefore, accord...

Embodiment 1

[0052] This embodiment provides an artificial stone and a preparation method thereof.

[0053] An artificial stone material, comprising the following raw material components in the following weight percentages:

[0054] 100 mesh limestone powder 80%

[0055] 55% phosphoric acid solution 15%

[0056] Metakaolin 5%.

[0057] A preparation method of artificial stone, comprising the following steps:

[0058] S10: provide limestone powder, phosphoric acid solution, and metakaolin according to the raw material components included in the artificial stone material of the present embodiment;

[0059] S20: firstly mix limestone powder and metakaolin evenly, then add phosphoric acid solution and quickly stir for 2 min to obtain slurry;

[0060] S30: injecting the slurry into the mold for 1 h of room temperature air curing, and then demoulding and performing room temperature air curing for 5 days to obtain artificial stone.

[0061] After testing, the apparent density of artificial s...

Embodiment 2

[0063] This embodiment provides an artificial stone and a preparation method thereof.

[0064] An artificial stone material, comprising the following raw material components in the following weight percentages:

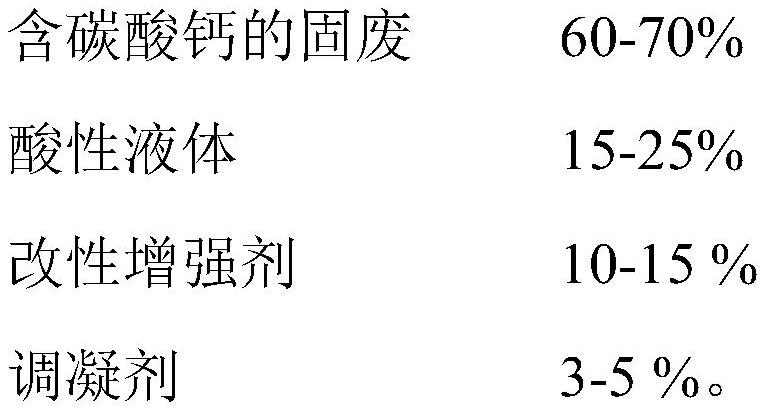

[0065]

[0066] A preparation method of artificial stone, comprising the following steps:

[0067] S10: Provide papermaking lime mud, shell residue, phosphoric acid solution, oxalic acid solution, bauxite, metakaolin, and organic phosphate according to the raw material components included in the artificial stone material of this embodiment;

[0068] S20: firstly mix white mud for papermaking, shell slag, bauxite, metakaolin, and organic phosphate, then add phosphoric acid solution and oxalic acid solution and stir quickly for 2 minutes to obtain a slurry;

[0069] S30: injecting the slurry into the mold for 60°C steam curing for 30 minutes, and then demoulding and performing 60°C steam curing for 1 day to obtain artificial stone.

[0070] After testing, the appar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com