Method for preparing sugarcane solid fertilizer from culture tail water filtration residues

A fertilizer and solid state technology, which is applied to the field of preparing sugarcane solid fertilizer by filtering residues of aquaculture tail water, can solve problems such as hindering the improvement of sugarcane yield and quality, uneven distribution of sugarcane nutrients, and declining sugarcane soil fertility, so as to improve fish meat quality, Achieve high-value utilization and reduce planting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

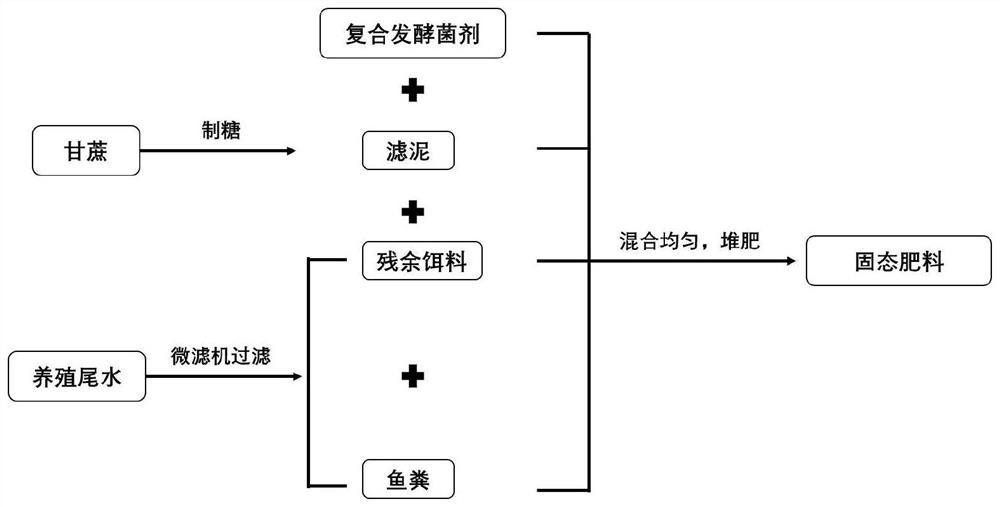

Method used

Image

Examples

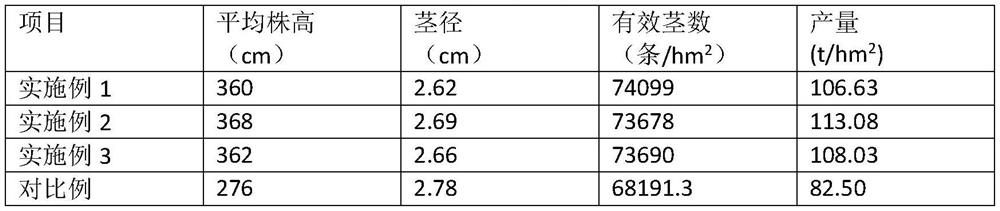

Embodiment 1

[0043] The raw materials were weighed according to the following parts by weight: 10 parts of fish manure, 10 parts of residual bait, 4 parts of sugarcane filter mud, and a compound fermentation bacterial agent equivalent to 0.25% of the weight of sugarcane filter mud was added.

[0044] The compound bacterial agent is domesticated bacteria freeze-dried powder, yeast freeze-dried powder, Pseudomonas aeruginosa freeze-dried powder and Bacillus freeze-dried powder, and the weight ratio is 3:2:2:1.

[0045] The preparation method of the composite solid compost is:

[0046] (1) Use microfilters with different small apertures to filter the tail water of culture, obtain organic matter such as fish manure and residual bait in turn, dry them, and save them for future use.

[0047] (2) Mix the sugarcane filter mud, fish manure, residual bait and compound fermentation inoculum in a ratio of 10:10:4:0.01 (the ratio of compound inoculum is 3:2:2:1), stir evenly, and pile them into a certa...

Embodiment 2

[0049] The raw materials were weighed according to the following parts by weight: 15 parts of fish manure, 15 parts of residual bait, 9 parts of sugarcane filter mud, and a compound fermentation bacterial agent equivalent to 0.25% of the weight of sugarcane filter mud was added.

[0050] The compound bacterial agent is domesticated bacteria freeze-dried powder, yeast freeze-dried powder, Pseudomonas aeruginosa freeze-dried powder and Bacillus freeze-dried powder, and the weight ratio is 3:2:3:1.5.

[0051] The preparation method of the composite solid compost is:

[0052] (1) Use microfilters with different small apertures to filter the tail water of culture, obtain organic matter such as fish manure and residual bait in turn, dry them, and save them for future use.

[0053] (2) Mix the sugarcane filter mud, fish manure, residual bait and compound fermentation inoculum in a ratio of 15:15:9:0.0225 (the ratio of compound inoculum is 4:2:3:1.5), stir evenly, and pile them into a...

Embodiment 3

[0055] The raw materials were weighed according to the following parts by weight: 12 parts of fish manure, 13 parts of residual bait, 5 parts of sugarcane filter mud, and a compound fermentation bacterial agent equivalent to 0.25% of the weight of sugarcane filter mud was added.

[0056] The compound bacterial agent is domesticated bacteria freeze-dried powder, yeast freeze-dried powder, Pseudomonas aeruginosa freeze-dried powder and Bacillus freeze-dried powder, and the weight ratio is 4:3:3:1.5.

[0057] The preparation method of the composite solid compost is:

[0058] (1) Use microfilters with different small apertures to filter the tail water of culture, obtain organic matter such as fish manure and residual bait in turn, dry them, and save them for future use.

[0059] (2) Mix the sugarcane filter mud, fish manure, residual bait and compound fermentation inoculum according to the ratio of 12:13:5:0.0125 (the ratio of compound inoculum is 3:1:2:1.5), stir evenly, and pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com