Room-temperature foaming silicone rubber foam material as well as preparation method and application thereof

A technology of foaming materials and room temperature foaming, which is applied in the direction of sound-generating devices and instruments, and can solve the problems that rock wool materials are difficult to meet the requirements, have many by-products, and the vulcanization speed of condensation-type silicone rubber is slow, so as to achieve low production cost and effective use Long life, good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

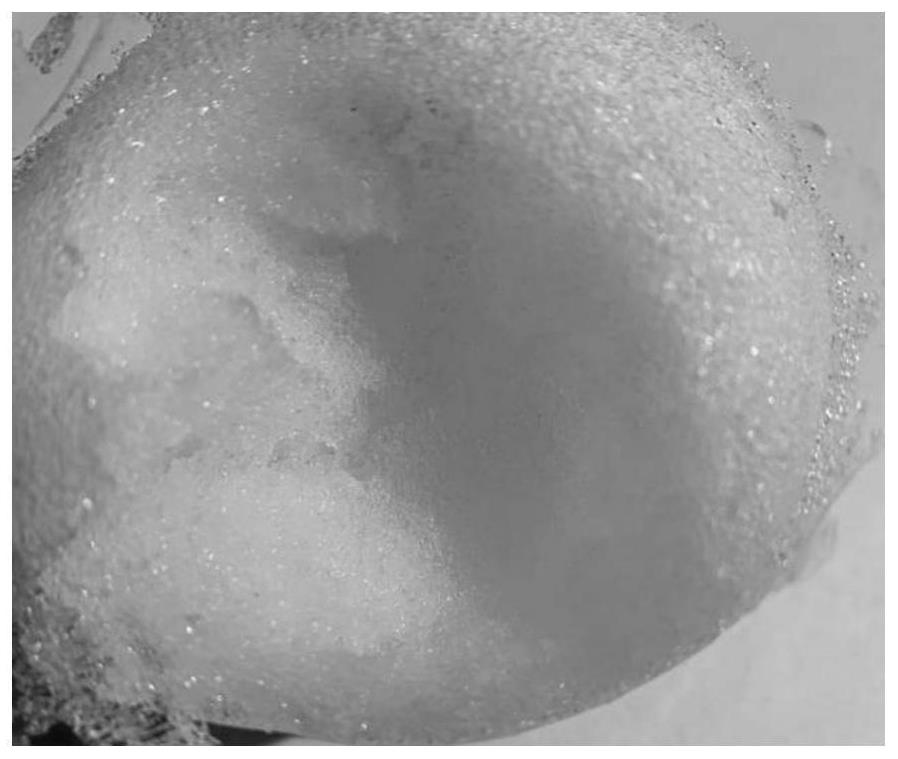

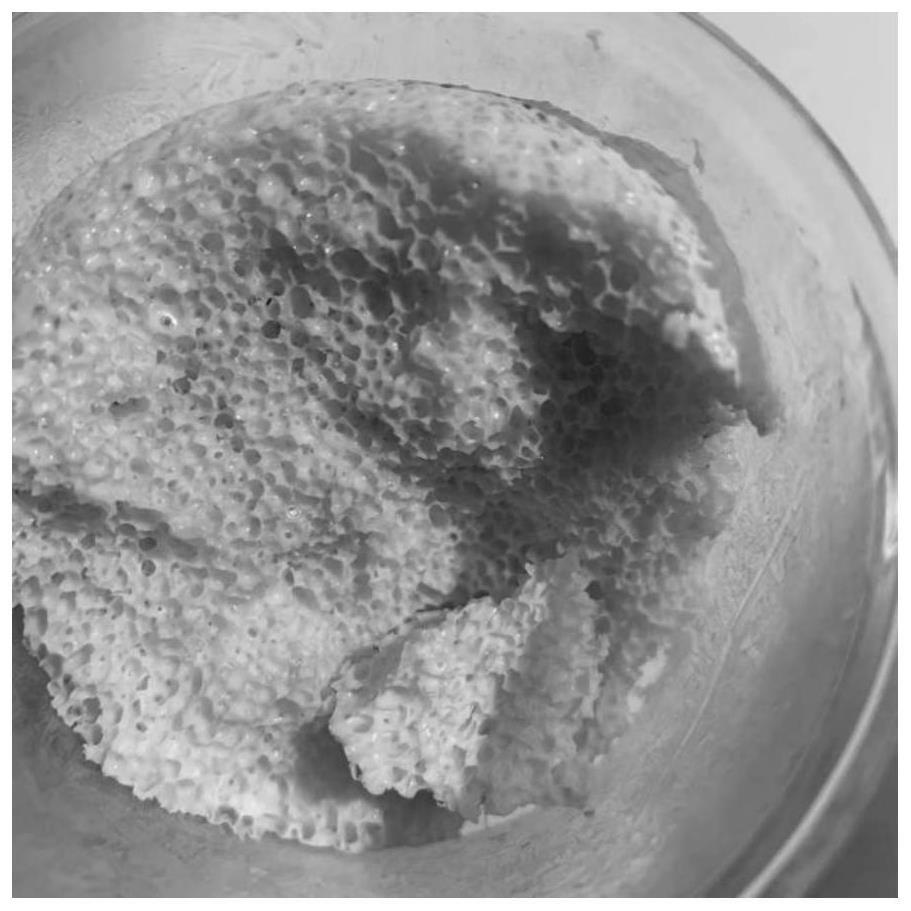

Image

Examples

Embodiment 1

[0034] Step 1, stir and mix 20 parts of 107 glue with a viscosity of 1000 mPa·s, 5 parts of vinyl silicone oil with a viscosity of 10000 mPa·s, 2 parts of hydroxy silicone oil, and 1 part of ethanol to obtain mixture A;

[0035] Step 2, add 0.1-5 parts of inhibitors and 0.1-5 parts of catalysts to mixture A, stir and mix evenly to obtain mixture B;

[0036] Wherein the inhibitor is 1-ethynyl-1-cyclohexanol, and the catalyst is a platinum complex catalyst with a platinum content of 1000-5000 ppm;

[0037] Step 3, in mixture B, add 10 parts of hydrogen-containing silicone oil, stir and mix evenly;

[0038] Step 4, place at room temperature for about 5 minutes to start vulcanization and foaming, and finally vulcanize and foam for 1 hour.

Embodiment 2

[0040] The structure of the room temperature foamed silicone rubber foam material prepared in Example 1 is the same, and the difference lies in the addition amount of ingredients and fillers.

[0041] Step 1: Mix 30 parts of 107 glue with a viscosity of 1000 mPa·s, 10 parts of vinyl silicone oil with a viscosity of 10000 mPa·s, 4 parts of hydroxy silicone oil, 2 parts of ethanol, and 5 parts of white carbon black to obtain mixture A;

[0042] Step 2, add 0.1 part of inhibitor and 0.5 part of catalyst to mixture A, stir and mix evenly to obtain mixture B;

[0043] Wherein the inhibitor is 3,5-dimethyl-1-hexyn-3-ol, and the catalyst is a platinum complex catalyst with a platinum content of 1000-5000 ppm;

[0044] Step 3, in mixture B, add 20 parts of hydrogen-containing silicone oil, stir and mix evenly;

[0045] Step 4, place at room temperature for about 5 minutes to start vulcanization and foaming, and finally vulcanize and foam for 2 hours.

Embodiment 3

[0047] The structure of the room temperature foamed silicone rubber foam material prepared in Example 1 is the same, and the difference lies in the addition amount of components and fillers.

[0048] Step 1, mix 40 parts of 107 glue with a viscosity of 1000 mPa s, 15 parts of vinyl silicone oil with a viscosity of 10000 mPa s, 6 parts of hydroxy silicone oil, 2 parts of ethanol, 5 parts of white carbon black, and 30 parts of calcium carbonate, stir and mix evenly to obtain mixture A;

[0049] Step 2, add 0.1 part of inhibitor and 0.5 part of catalyst to mixture A, stir and mix evenly to obtain mixture B;

[0050] Wherein the inhibitor is 3-methyl-1-dodecyn-3-ol, and the catalyst is a platinum-gold complex catalyst with a platinum content of 1000-5000 ppm;

[0051] Step 3, in mixture B, add 10 parts of hydrogen-containing silicone oil, stir and mix evenly;

[0052] Step 4, place at room temperature for about 5 minutes to start vulcanization and foaming, and finally vulcanize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com