High-strength natural polymer hydrogel as well as preparation method and application thereof

A natural polymer, hydrogel technology, applied in prosthesis, bandages, medical science and other directions, can solve the problem of human carcinogenic risk and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

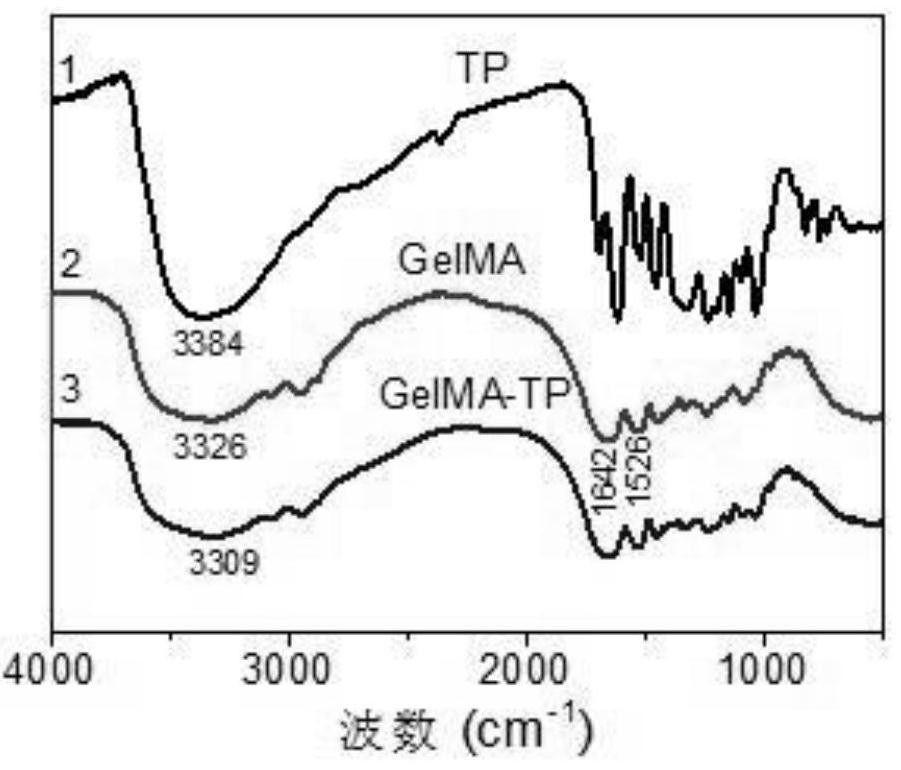

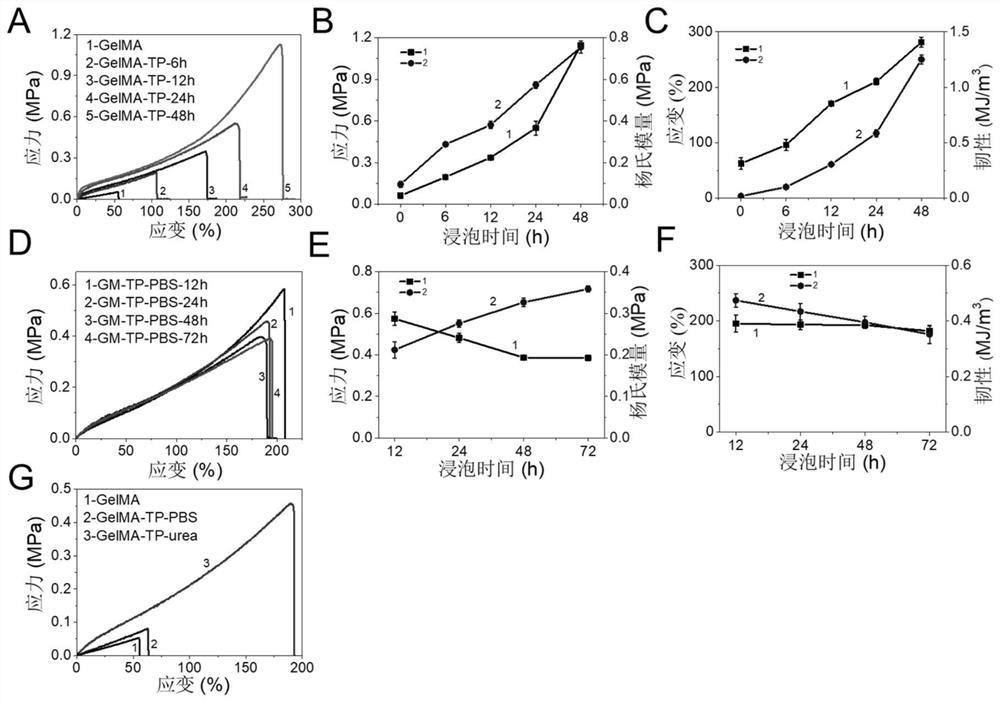

Embodiment 1

[0025] Weigh 0.2g of GelMA into a 10mL centrifuge tube with a tray balance, then add 1mL of deionized water to dissolve it, and finally add 4uL of 1173 to the centrifuge tube and mix it well. After sealing, it was placed in a UV cross-linking apparatus for UV irradiation for 40 min. GelMA-TP hydrogels were obtained by soaking the prepared gels in 20% TP solution at 37 °C for 48 hours.

Embodiment 2

[0027] Weigh 0.2g of GelMA into a 10mL centrifuge tube with a tray balance, then add 1mL of deionized water to dissolve it, and finally add 4uL of 1173 to the centrifuge tube and mix it well. After sealing, it was placed in a UV cross-linking apparatus for UV irradiation for 40 min. The prepared gel was soaked in 25% TP solution at 38℃ for 5 hours to obtain GelMA-TP hydrogel.

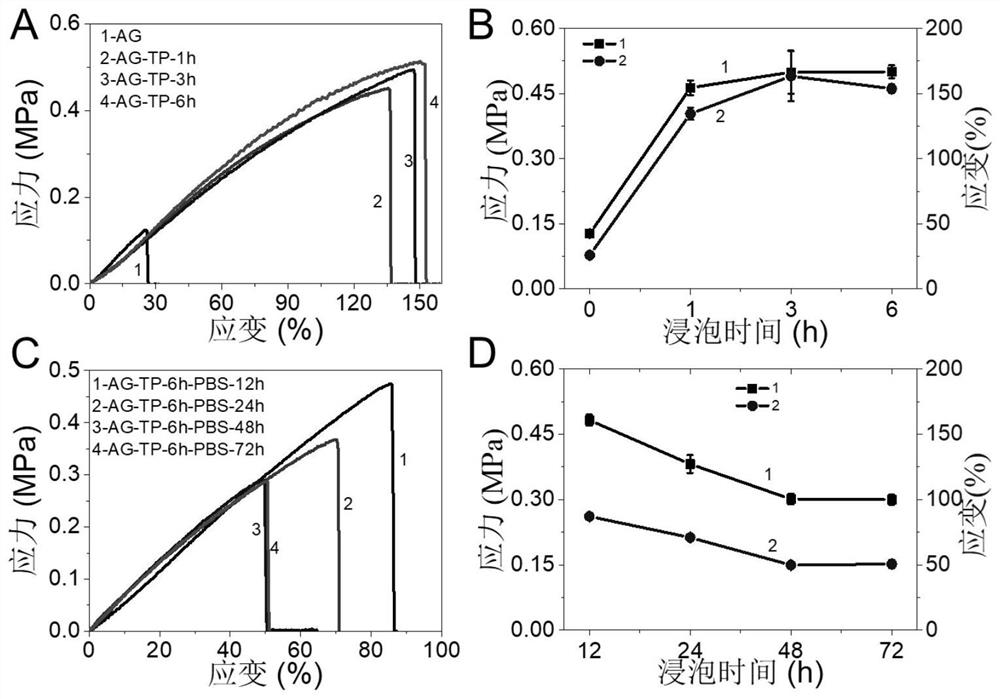

Embodiment 3

[0029] Weigh 0.3 g of AG into a 100 mL beaker with a tray balance, then add 10 mL of deionized water to heat it to 90 °C to dissolve it, and put it into a mold while it is still hot to make a sheet-like gel. The prepared gel was soaked in 20% TP solution at 37 °C for 6 hours to obtain AG-TP hydrogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com