Bismuth-based composite photocatalyst as well as preparation method and application thereof

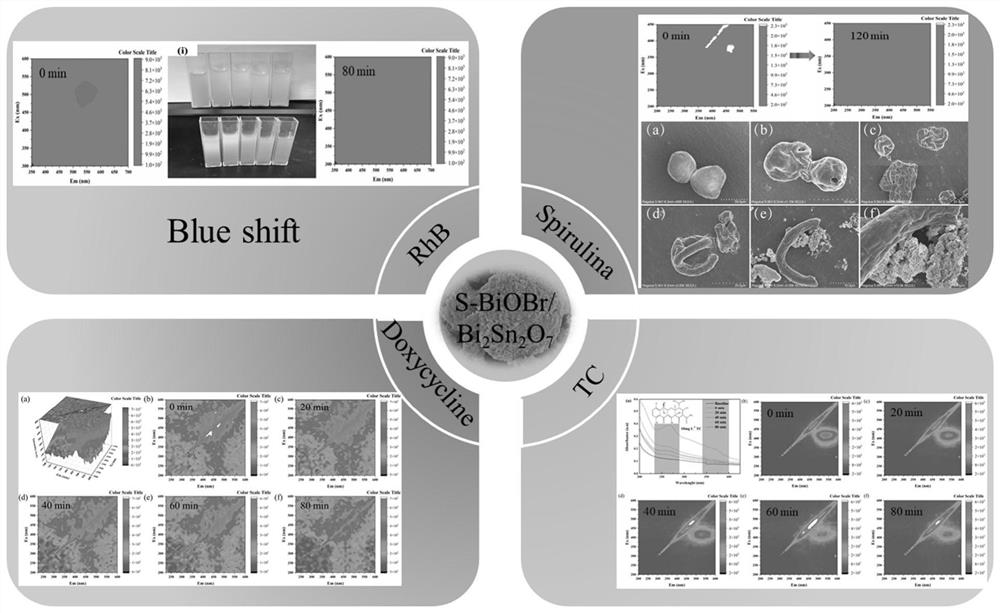

A technology of composite light and catalyst, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of low visible light capture efficiency and slow degradation of pollutants, and achieve superior degradation performance and simple process. , the effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

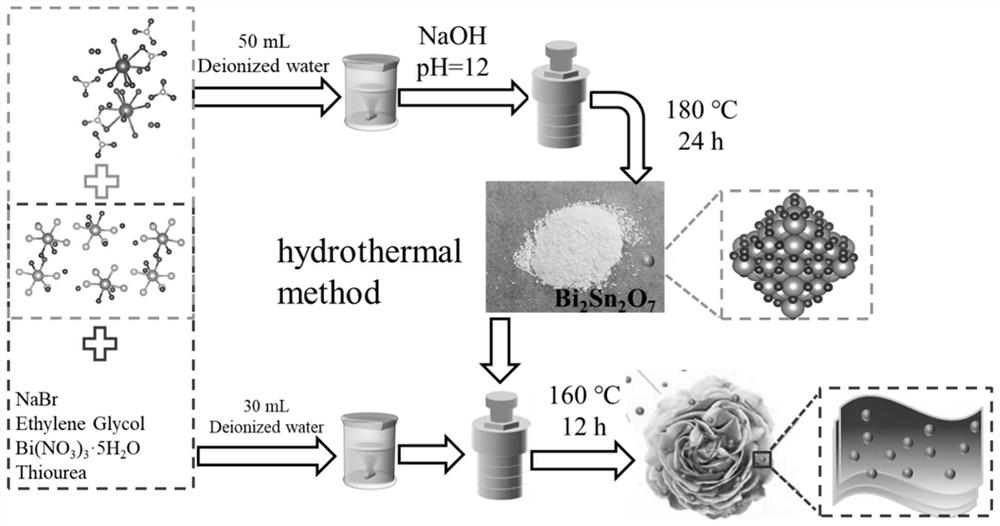

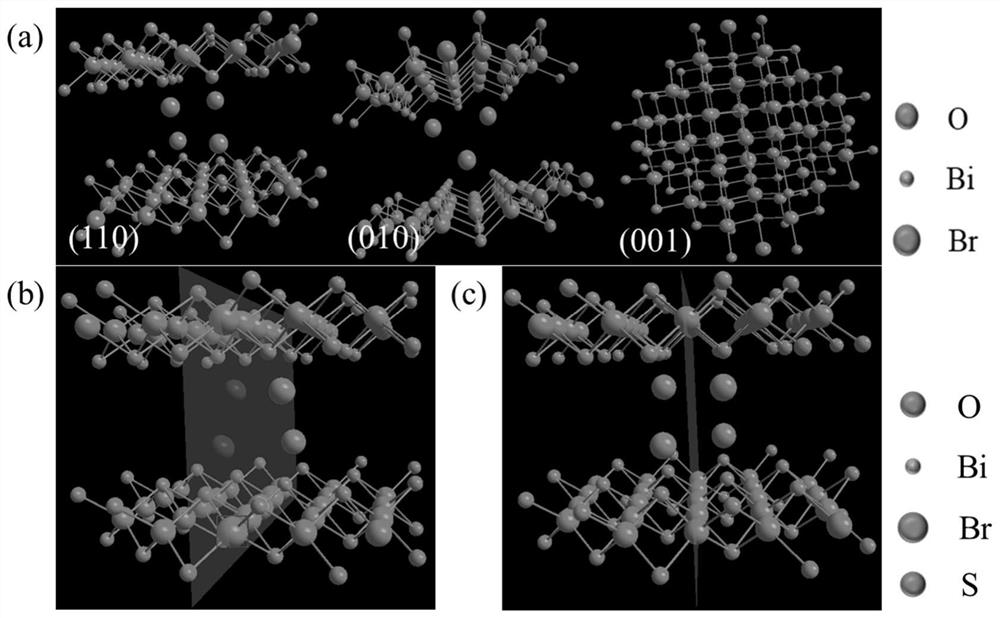

[0060] The technical scheme adopted in the present invention is a preparation method of a sulfur-doped bismuth oxybromide / bismuth stannate composite photocatalyst, comprising the following steps:

[0061] (1) Bi 2 Sn 2 O 7 preparation

[0062] Synthesis of Bi by Hydrothermal Method 2 Sn 2 O 7 nanoparticles. SnCl 4 .5H 2 O and Bi (NO 3 ) 3 ·5H 2 Disperse O in deionized water, stir and mix evenly; the molar ratio of bismuth nitrate pentahydrate and tin tetrachloride pentahydrate is 1:1; use NaOH to adjust the pH value to 12, and wait for it to be dispersed evenly. Placed in a Teflon high pressure reactor, the temperature is 170 ~ 190 ℃, and the reaction is 20 ~ 26h. Wash 3-4 times with deionized water and absolute ethanol. After that, it was placed in a drying oven and dried at 60 °C for 24 h to obtain Bi 2 Sn 2 O 7 sample.

[0063] (2)S-BiOBr / Bi 2 Sn 2 O 7 Preparation of composite photocatalysts

[0064] Preparation of S-BiOBr / Bi by Hydrothermal Method 2 S...

Embodiment 1

[0069] Bi 2 Sn 2 O 7 The preparation of Bi was synthesized by hydrothermal method 2 Sn 2 O 7 Nanoparticles:

[0070] 0.005mol SnCl 4 .5H 2 O (1.442g) and 0.005mol Bi (NO 3 ) 3 ·5H 2 O (1.94 g) was dispersed into 25 mL of deionized water and stirred for 20 min. The two solutions were mixed and stirred for 30 min. Use 2mol L -1 The pH was adjusted to 12 with NaOH, and it was dispersed uniformly. It was placed in a Teflon autoclave, the temperature was 180°C, and the reaction was carried out for 24h. Wash 3-4 times with deionized water and absolute ethanol. After that, it was placed in a drying oven and dried at 60 °C for 24 h to obtain Bi 2 Sn 2 O 7 sample.

[0071] S-BiOBr / Bi 2 Sn 2 O 7 Preparation of composite photocatalysts,

[0072] Preparation of S-BiOBr / Bi by Hydrothermal Method 2 Sn 2 O 7 : 1 mmol Bi(NO 3 ) 3 ·5H 2 O and 0.01mmolBi 2 Sn 2 O 7 , dissolved in 5 mL of ethylene glycol solution, stirred for 20 min, and named solution A. To 30 mL...

Embodiment 2

[0074] Bi 2 Sn 2 O 7 The preparation of Bi was synthesized by hydrothermal method 2 Sn 2 O 7 Nanoparticles:

[0075] 0.005mol SnCl 4 .5H 2 O (1.442g) and 0.005mol Bi (NO 3 ) 3 ·5H 2 O (1.94 g) was dispersed into 25 mL of deionized water and stirred for 20 min. The two solutions were mixed and stirred for 30 min. Use 2mol L -1 The pH was adjusted to 12 with NaOH, and it was dispersed uniformly. It was placed in a Teflon autoclave, the temperature was 180°C, and the reaction was carried out for 24h. Wash 3-4 times with deionized water and absolute ethanol. After that, it was placed in a drying oven and dried at 60 °C for 24 h to obtain Bi 2 Sn 2 O 7 sample.

[0076] S-BiOBr / Bi 2 Sn 2 O 7 Preparation of composite photocatalysts,

[0077] Preparation of S-BiOBr / Bi by Hydrothermal Method 2 Sn 2 O 7 : 1 mmol Bi(NO 3 ) 3 ·5H 2 O and 16 mg (0.02 mmol) Bi 2 Sn 2 O 7 , dissolved in 5 mL of ethylene glycol solution, sonicated and added 1 mmol Bi(NO 3 ) 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com