Recovery method of waste etching liquid

A recovery method and waste liquid technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problem that copper-containing waste etching liquid cannot be effectively recycled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The composition of the acid copper-containing etching waste liquid adopted in the embodiment is aluminum chloride, ammonium chloride, cupric chloride, phosphoric acid, aluminum 2000ppm, copper 80000ppm, total phosphorus 2000ppm, ammonium root 8000ppm, and the composition of the alkaline etching waste liquid is Ammonia water, ammonium chloride, copper chloride, ammonia nitrogen 120000ppm, copper 90000ppm.

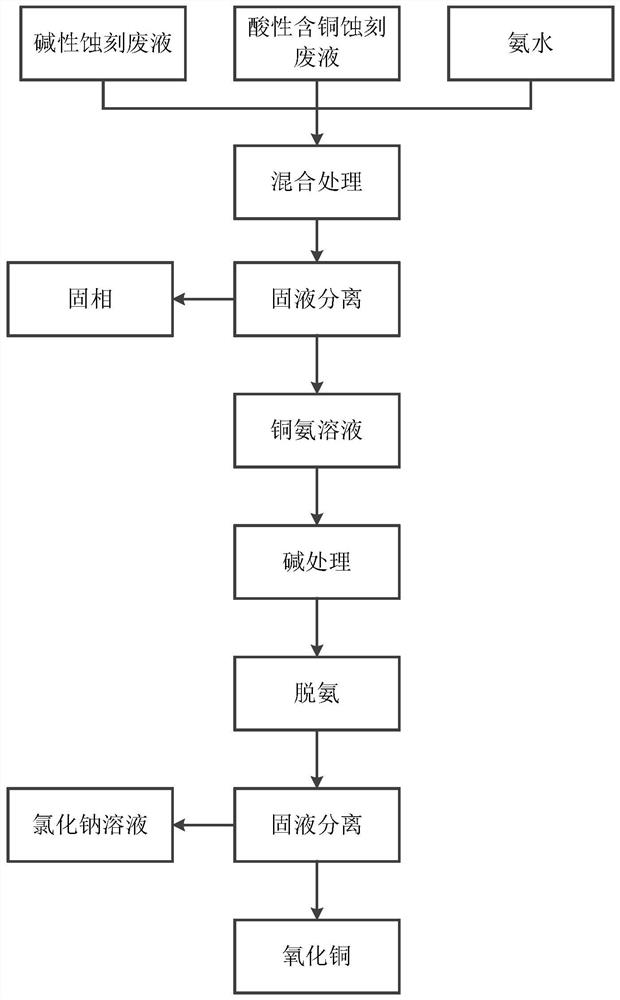

[0036] The present embodiment provides a method for recycling waste etching solution, such as figure 1 As shown, the recovery method includes:

[0037]The acid copper-containing etching waste liquid, the alkaline etching waste liquid and the ammonia water are mixed and processed, and the solid phase and the cuproammonium solution are obtained through solid-liquid separation; the acid copper-containing etching waste liquid, the alkaline etching waste liquid and the ammonia water are obtained in the mixed treatment. The mass ratio of 1:0.7:1.3; the time of the mixing t...

Embodiment 2

[0041] The composition of the acid copper-containing etching waste liquid adopted in the embodiment is aluminum chloride, ammonium chloride, cupric chloride, phosphoric acid, aluminum 1000ppm, copper 100000ppm, total phosphorus 5000ppm, ammonium root 2400ppm, and the composition of the alkaline etching waste liquid is Ammonia, ammonium chloride, copper chloride, ammonia nitrogen 100000ppm, copper 86500ppm.

[0042] The present embodiment provides a method for recycling waste etching solution, the recycling method comprising:

[0043] The acid copper-containing etching waste liquid, the alkaline etching waste liquid and the ammonia water are mixed and processed, and the solid phase and the cuproammonium solution are obtained through solid-liquid separation; the acid copper-containing etching waste liquid, the alkaline etching waste liquid and the ammonia water are obtained in the mixed treatment. The mass ratio of 1:0.5:1.5; the time of the mixing treatment is 30min;

[0044] ...

Embodiment 3

[0047] Aluminum chloride, ammonium chloride, cupric chloride, phosphoric acid, aluminum 3394ppm, copper 102392ppm, total phosphorus 3432ppm, ammonium root 3429ppm of the acid copper-containing etching waste liquid adopted in the embodiment, the composition of the alkaline etching waste liquid is ammoniacal liquor, Ammonium chloride, copper chloride, ammonia nitrogen 95085ppm, copper 8764ppm.

[0048] The present embodiment provides a method for recycling waste etching solution, the recycling method comprising:

[0049] The acid copper-containing etching waste liquid, the alkaline etching waste liquid and the ammonia water are mixed and processed, and the solid phase and the cuproammonium solution are obtained through solid-liquid separation; the acid copper-containing etching waste liquid, the alkaline etching waste liquid and the ammonia water are obtained in the mixed treatment. The mass ratio of 1:0.8:1.2; the time of the mixing treatment is 45min;

[0050] The obtained cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com