Desulfurization and calcium removal method for fly ash water washing liquid

A fly ash and water washing technology, which is applied in the field of fly ash water treatment, can solve the problems of inconvenient raw materials and achieve the effects of improved mixing effect, good removal effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

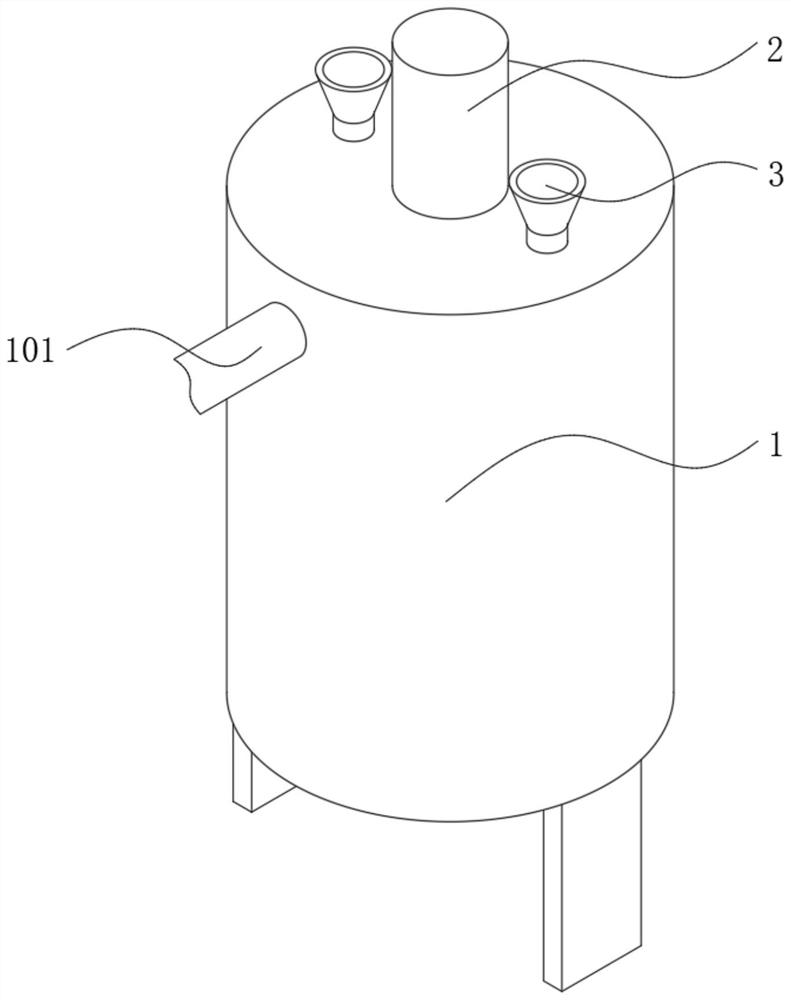

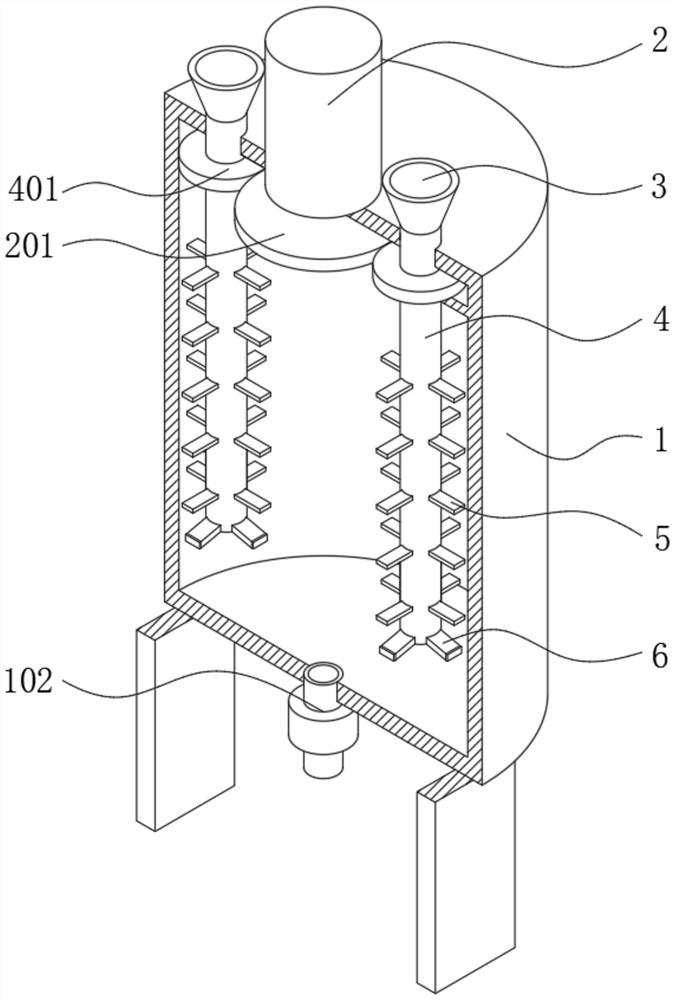

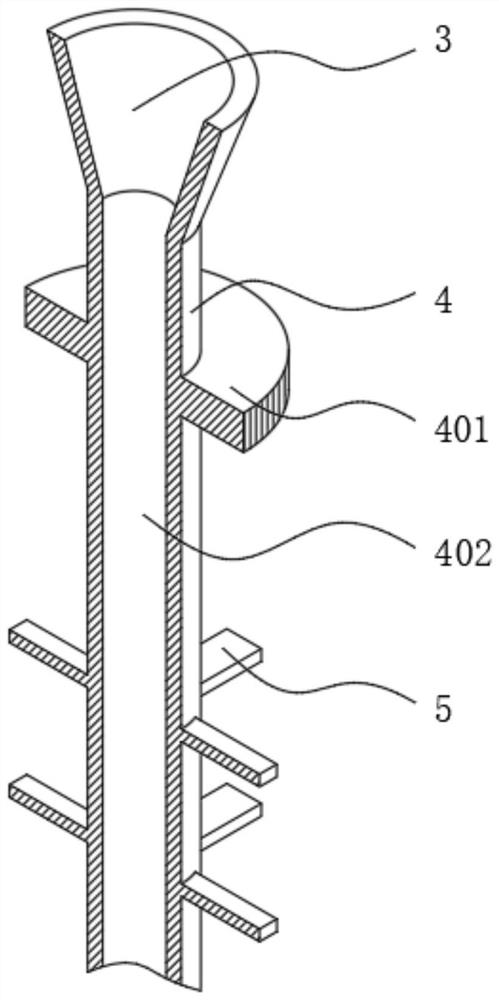

[0037] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. The embodiments described below with reference to the accompanying drawings are exemplary and are only used to explain the present invention, and should not be construed as a limitation of the present invention.

[0038] The embodiments of the present invention will be described below based on the overall structure of the present invention.

[0039] A method for desulfurization and decalcification of fly ash washing liquid. The fly ash washing waste water after decalcification is heated to 110°C-140°C, evaporated and concentrated to a certain concentration (the control cannot exceed the concentration point where potassium chloride is precipitated), and chlorine is precipitated by crystallization. After the sodium is dissolved, it is collected by a centrifuge, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com