Device and method for recycling hydrogen production acidic water

A technology of acidic water and carbonate, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., to achieve the effect of reducing environmental CO2 emissions and solving the problem of acidic water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

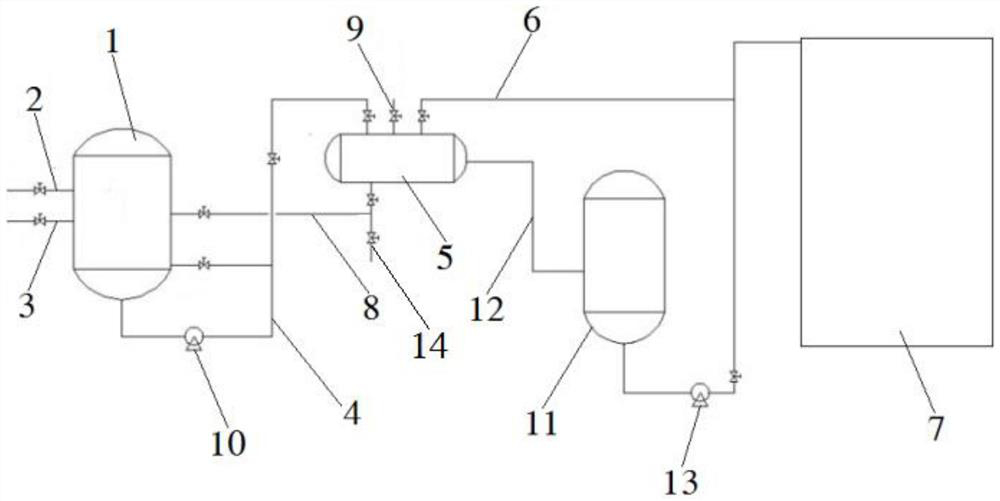

[0023] refer to figure 1 , the embodiment of the present invention provides a hydrogen production acid water recycling device, including: a mixing tank 1, a membrane separator 5 and an evaporative dryer 7; the mixing tank 1 is connected with an acid water inlet pipeline 2 and an alkali Liquid inlet pipeline 3, the mixing tank 1 is also connected with a mixed liquid outlet pipeline 4; the inlet end of the membrane separator 5 is connected with the mixed liquid outlet pipeline 4, and the membrane separator 5 is connected to the A concentration outlet pipeline 6 is also provided; the inlet of the evaporative dryer 7 is communicated with the concentration outlet pipeline 6 .

[0024] The hydrogen production unit produces a higher CO 2 The acid water is introduced into the mixing tank 1 through the acid water inlet pipeline 2, and the sodium hydroxide solution is introduced through the lye water inlet pipeline 3. The mixing tank 1 is provided with an acid-base corrosion-proof stir...

Embodiment 2

[0029] refer to figure 1 , On the basis of Embodiment 1, the membrane separator 5 is also provided with a return water pipeline 8 , and the return water pipeline 8 leads back to the mixing tank 1 .

[0030] The lower area of the filter membrane in the membrane separator 5 is connected to the return water pipeline 8, and the return water pipeline 8 is connected to the mixing tank 1. If the membrane fails, the water separated by the filter membrane of the membrane separator 5 can be returned to the mixing tank. In the tank 1, it can also be discharged to other places through the return water bypass 14 on the return water pipeline 8.

Embodiment 3

[0032] refer to figure 1 , On the basis of Example 1, the membrane separator 5 is also provided with a fresh water inlet pipeline 9 .

[0033] The membrane separator 5 can also pass fresh water through the fresh water inlet pipe 9 to clean the concentration outlet pipe 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com