Purification method and device for continuous rectification separation of ibuprofen intermediate raw material

A purification method and rectification separation technology, which is applied in the purification field of continuous rectification separation of ibuprofen intermediate raw materials, and can solve the problems of insufficient recovery rate and low recovery rate of isobutylbenzene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

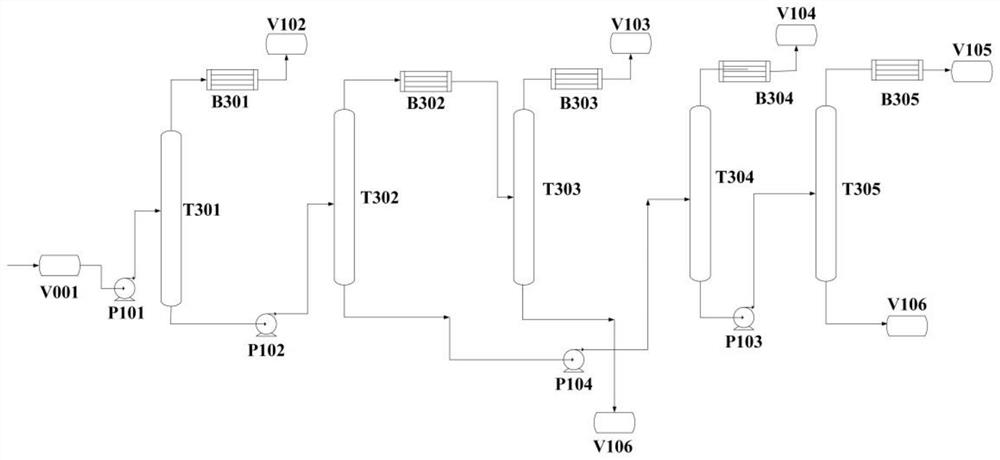

[0063] The feed flow rate of the synthesis liquid is 900kg / h, the feed temperature is 25°C, and the feed pressure is 2atm, which contains 50% by weight of isobutylbenzene, 35% by weight of toluene, 5% by weight of 4-methyl-1-pentene, and 5% by weight of n-butyl benzene. Benzene 5wt%, 1-ethyl-2-vinylbenzene 5wt%; the actual number of trays in the T301 detetramethyl tower is 25, and the best feeding position is the 13th tray in the order from top to bottom, reflux The ratio is 1, the pressure is 1MPa; the actual number of trays of the toluene recovery tower T302 is 50, the best feeding position is the 10th tray from top to bottom, the reflux ratio is 1.2, and the pressure is 0.015MPa; toluene The actual number of trays of tower T303 is 44, the best feeding position is the 40th tray in the order from top to bottom, the reflux ratio is 2.5, and the pressure is 0.07MPa; the actual number of trays of isobutylbenzene tower T304 There are 110 plates, the best feeding position is the 7...

Embodiment 2

[0065] The feed flow rate of the synthesis liquid is 2000kg / h, the feed temperature is 25°C, and the feed pressure is 2atm, which contains 55wt% of isobutylbenzene, 35wt% of toluene, 4wt% of 4-methyl-1-pentene, n-butyl 4wt% of benzene, 2wt% of 1-ethyl-2-vinylbenzene; the actual number of trays in the T301 detetramethyl tower is 30, and the best feeding position is the 15th tray in the order from top to bottom, reflux The ratio is 1, the pressure is 1MPa; the actual number of trays of the toluene recovery tower T302 is 60, the best feeding position is the 13th tray from top to bottom, the reflux ratio is 1.5, and the pressure is 0.01MPa; The actual number of trays of tower T303 is 42, the best feeding position is the 40th tray in the order from top to bottom, the reflux ratio is 2.8, and the pressure is 0.015MPa; the actual number of trays of isobutylbenzene tower T304 There are 102 plates, the best feeding position is the 82nd plate in the order from top to bottom, the reflux ...

Embodiment 3

[0067]The feed flow rate of the synthesis liquid is 5000kg / h, the feed temperature is 25°C, and the feed pressure is 2atm, which contains 53wt% of isobutylbenzene, 38wt% of toluene, 3wt% of 4-methyl-1-pentene, n-butylene 3 wt% of benzene, 3 wt% of 1-ethyl-2-vinylbenzene; the actual number of trays of the T301 detetramethyl tower is 22, and the best feeding position is the 12th tray from top to bottom, reflux The ratio is 1.2, the pressure is 1MPa; the actual number of trays of the toluene recovery tower T302 is 55, the best feeding position is the 15th tray in the order from top to bottom, the reflux ratio is 1.8, and the pressure is 0.01MPa; toluene The actual number of trays of tower T303 is 38, the best feeding position is the 35th tray in the order from top to bottom, the reflux ratio is 2.1, and the pressure is 0.05MPa; the actual number of trays of isobutylbenzene tower T304 The best feeding position is the 63rd plate from top to bottom, the reflux ratio is 3.9, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com