Method for improving gel strength of starch sodium octenylsuccinate

A technology of octenyl succinic acid and octenyl succinic anhydride, which is applied in the field of improving the gel strength of sodium starch octenyl succinate, can solve the problems of limited application, and achieve the solution of limited application, simple and easy operation, Optimizing the effect of functional features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

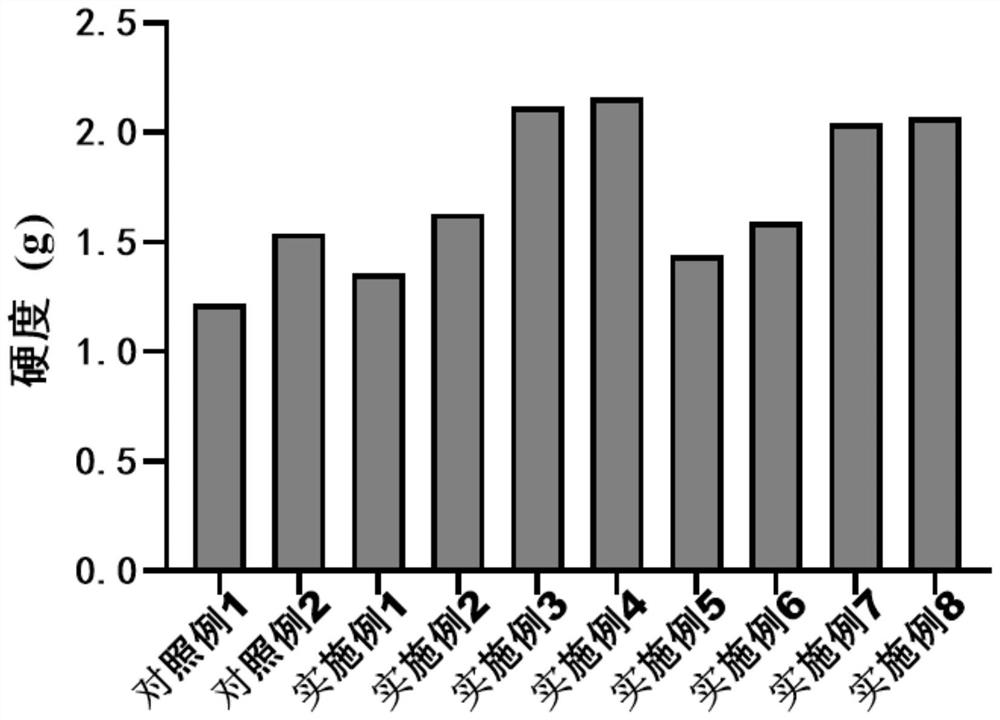

Embodiment 1

[0050] (1) Compounding of starch: add waxy rice starch and waxy potato starch into the beaker according to the compounding ratio of 8:2, the ratio of starch to water is 1:5 (W:V), and the magnetic stirring time is For 0.6 h, the starch slurry was suction filtered, and then filtered with anhydrous ethanol for 3 times to remove the water, then placed in a 37° C. oven to dry, ground in a mortar and filtered with a 200-mesh sieve.

[0051] (2) Modification of starch: Accurately weigh 20g of compound starch into a 250mL beaker, add 45mL of water, continue stirring with a magnetic stirrer (400rpm), and adjust the pH of the starch slurry to 8.5 with 2% sodium hydroxide solution , 0.6 mL of octenyl succinic anhydride was added dropwise, during the reaction, the pH of the reaction was kept constant by adding the above-mentioned lye solution, and after the reaction was continued for 4 h, the pH of the starch slurry was adjusted to neutral with 2% hydrochloric acid, and centrifuged Remov...

Embodiment 2

[0056] (1) Compounding of starch: add waxy rice starch and waxy potato starch into the beaker according to the compounding ratio of 6:4, the ratio of starch to water is 1:5 (W:V), and the magnetic stirring time is For 0.6 h, the starch slurry was suction filtered, and then filtered with anhydrous ethanol for 3 times to remove the water, then placed in a 37° C. oven to dry, ground in a mortar and filtered with a 200-mesh sieve.

[0057] (2) Modification of starch: Accurately weigh 20g of compound starch into a 250mL beaker, add 45mL of water, continue stirring with a magnetic stirrer (400rpm), and adjust the pH of the starch slurry to 8.5 with 2% sodium hydroxide solution , 0.6 mL of octenyl succinic anhydride was added dropwise, during the reaction, the pH of the reaction was kept constant by adding the above-mentioned lye solution, and after the reaction was continued for 4 h, the pH of the starch slurry was adjusted to neutral with 2% hydrochloric acid, and centrifuged Remov...

Embodiment 3

[0062] (1) Compounding of starch: add waxy rice starch and waxy potato starch into the beaker according to the compounding ratio of 4:6, the ratio of starch to water is 1:5 (W:V), and the magnetic stirring time is For 0.6 h, the starch slurry was suction filtered, and then filtered with anhydrous ethanol for 3 times to remove the water, then placed in a 37° C. oven to dry, ground in a mortar and filtered with a 200-mesh sieve.

[0063] (2) Modification of starch: Accurately weigh 20g of compound starch into a 250mL beaker, add 45mL of water, continue stirring with a magnetic stirrer (400rpm), and adjust the pH of the starch slurry to 8.5 with 2% sodium hydroxide solution , 0.6 mL of octenyl succinic anhydride was added dropwise, during the reaction, the pH of the reaction was kept constant by adding the above-mentioned lye solution, and after the reaction was continued for 4 h, the pH of the starch slurry was adjusted to neutral with 2% hydrochloric acid, and centrifuged Remov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com