Novel single-component adhesive and preparation method thereof

A single-component, adhesive technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of high temperature resistance, poor thermal shock resistance, etc., achieve high shear strength, economical High efficiency and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

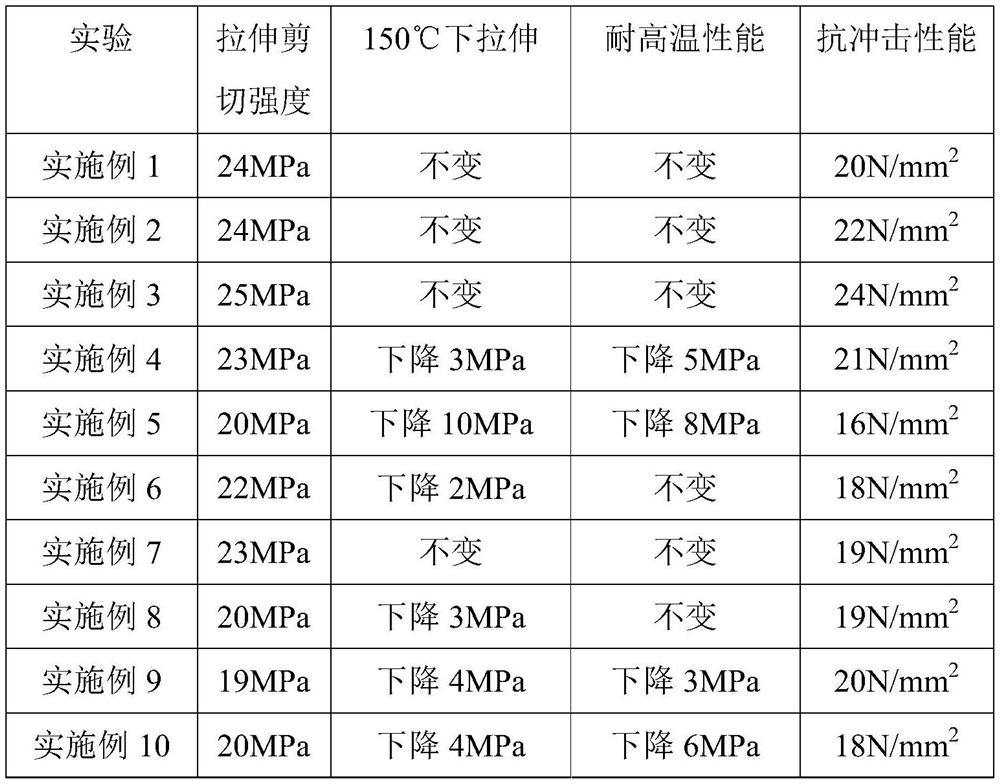

Examples

preparation example Construction

[0044] In this application, the ground black pulp can be made and purchased; there is no special restriction on the purchase of the manufacturer, and the preparation method can refer to the following steps:

[0045] Mix carbon black and 128 base resin in a weight ratio of 1:1.8 and grind to get it.

[0046] The carbon black is commercially available, and the 128 matrix resin is purchased from Jiangsu Yangnong Chemical Co., Ltd.

[0047] In some preferred embodiments, the filler is selected from one or more compounds of calcium carbonate, mica powder, talc, and barium carbonate.

[0048] In some preferred embodiments, the filler is selected from calcium carbonate and mica powder.

[0049] In some preferred embodiments, the weight ratio of calcium carbonate and mica powder is 26:(2-3).

[0050] During the experiment, the applicant found that although the latent curing agent selected to add improved the stability of the adhesive, the applicant found that the addition of the lat...

Embodiment 1

[0071] A new type of one-component adhesive, the preparation raw materials are calculated in parts by weight, including: 20 parts of epoxy resin, 25 parts of modified epoxy resin, 0.1 part of fumed silica, 1 part of black paste, 0.001 part of defoamer, 0.05 part of joint agent, 5 parts of curing agent and 25 parts of filler.

[0072] The epoxy resin is bisphenol A type epoxy resin, model E51, purchased from Guangxi Zhechuang Chemical Co., Ltd.;

[0073] Described modified epoxy resin is polyurethane modified epoxy resin, model EPU-303, purchased from Hehe High-tech Materials (Shanghai) Co., Ltd.;

[0074] Described fumed silica is hydrophobic silica, purchased from Weifang Hengshuo Nanomaterials Co., Ltd.;

[0075] The black slurry is prepared in an experiment, and the preparation method is as follows: mixing carbon black and 128 matrix resin at a weight ratio of 1:1.8, grinding, and obtaining.

[0076] Described 128 matrix resin was purchased from Jiangsu Yangnong Chemical ...

Embodiment 2

[0086] A new type of one-component adhesive, the preparation raw materials are calculated in parts by weight, including: 35 parts of epoxy resin, 40 parts of modified epoxy resin, 1 part of fumed silica, 5 parts of black paste, 0.005 part of defoamer, 0.5 part of joint agent, 20 parts of curing agent and 50 parts of filler.

[0087] The epoxy resin is bisphenol A type epoxy resin, model E51, purchased from Guangxi Zhechuang Chemical Co., Ltd.;

[0088] Described modified epoxy resin is polyurethane modified epoxy resin, model EPU-303, purchased from Hehe High-tech Materials (Shanghai) Co., Ltd.;

[0089] Described fumed silica is hydrophobic silica, purchased from Weifang Hengshuo Nanomaterials Co., Ltd.;

[0090] The black slurry is prepared in an experiment, and the preparation method is as follows: mixing carbon black and 128 matrix resin at a weight ratio of 1:1.8, grinding, and obtaining.

[0091] Described 128 matrix resin was purchased from Jiangsu Yangnong Chemical C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com