Metal etching liquid and preparation method and etching method thereof

A metal etching and etching technology, which is applied in the field of touch control and display, can solve the problems of poor environmental protection and strong smell of aluminum etching solution, and achieve the effects of good environmental protection, stable etching performance and good etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0085] Correspondingly, the present application also provides a method for preparing the above-mentioned metal etching solution, which may include, for example, the following steps: mixing the components according to the proportions.

[0086] Preferably, during the mixing process, the dissolution can be accelerated by means of stirring or the like to form a uniform etching solution.

[0087] In addition, the present application also provides a method for etching a multi-layer metal containing molybdenum and aluminum, for example, the method may include the following steps: etching the multi-layer metal containing molybdenum and aluminum with the above-mentioned metal etching solution.

[0088] For example, the to-be-etched part of the multi-layer metal containing molybdenum and molybdenum can be placed in the above-mentioned metal etching solution for etching, which can effectively obtain the required etching morphology and has excellent etching performance.

[0089] Wherein, ...

Embodiment 1-8

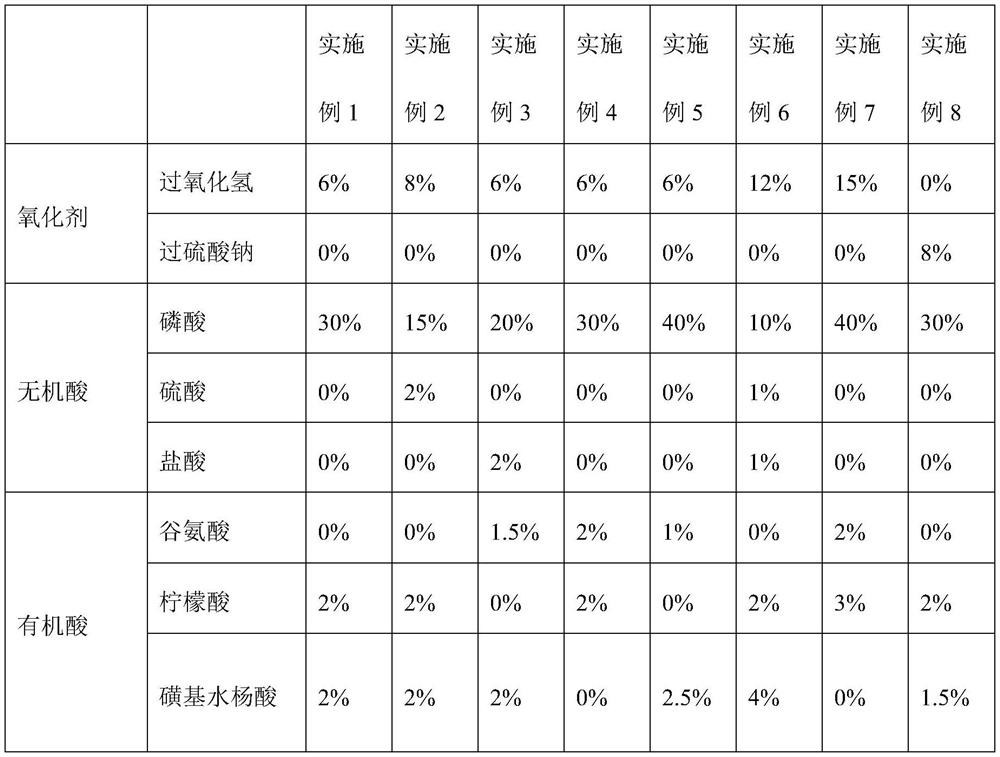

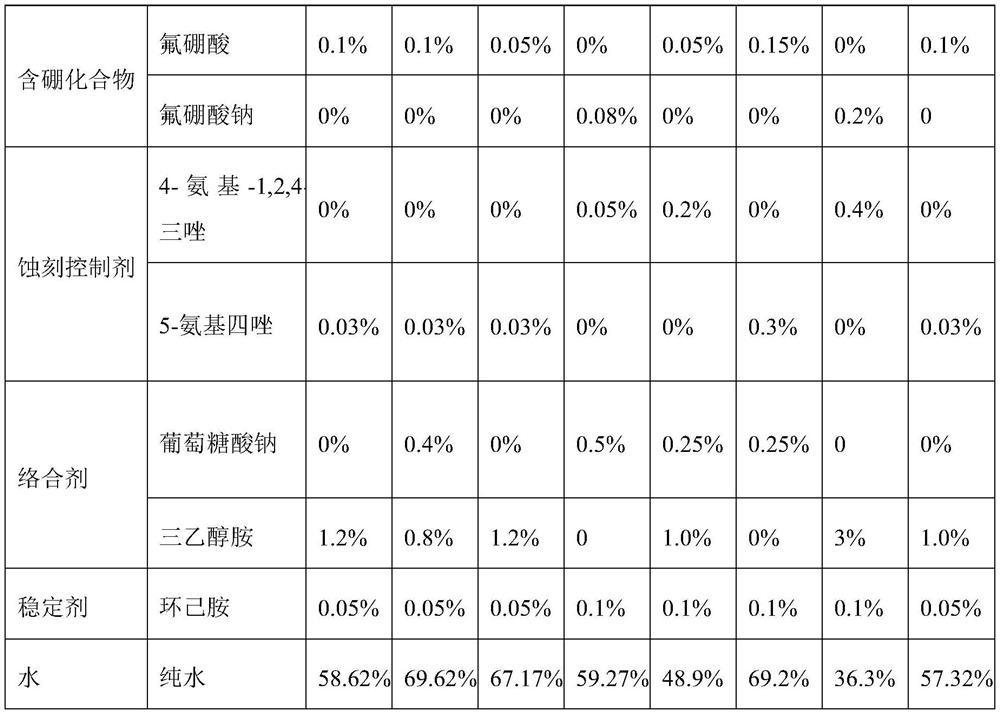

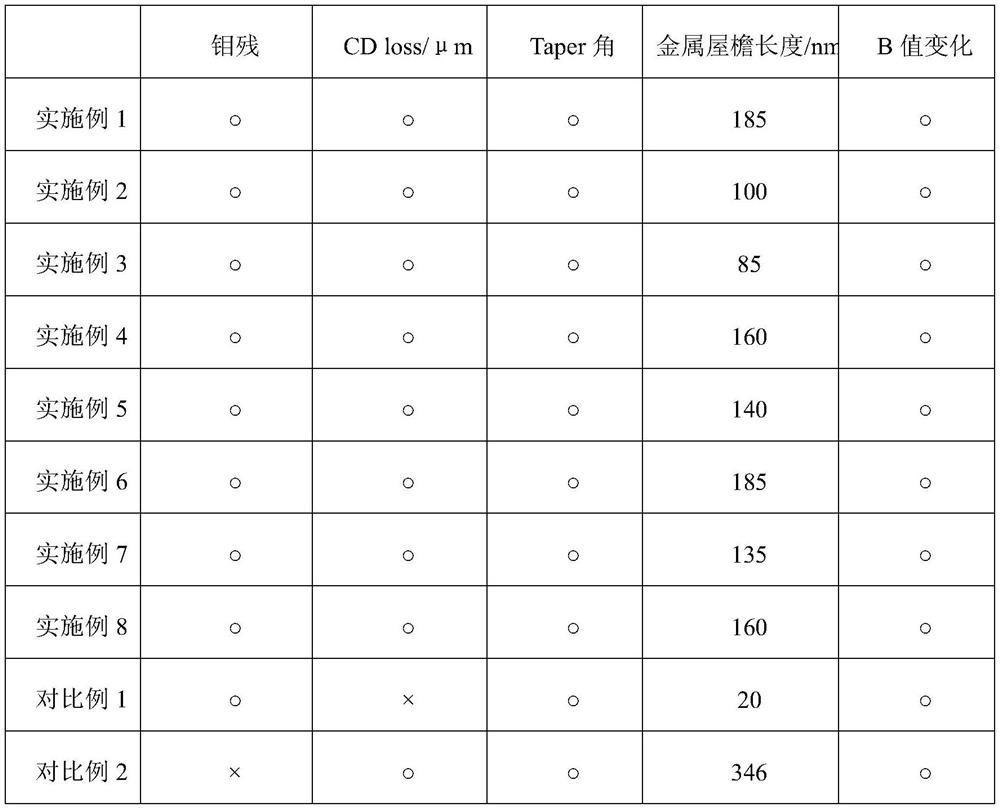

[0095] Embodiments 1-8 correspondingly provide 8 kinds of metal etching solutions, and the preparation methods thereof are all the same, that is, by mixing oxidant, inorganic acid, organic acid, boron-containing compound, etching control agent, complexing agent, stabilizer and water in proportions. Stir and mix at 25°C for 30 minutes, and then filter through a 0.22 μm filter element.

[0096] The formula of the metal etching solution that embodiment 1-8 provides is as shown in table 1:

[0097] Table 1 formula composition

[0098]

[0099]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap