Extrusion processing method of plant meat tissue protein

A technology of extrusion processing and plant protein, which is applied in the direction of plant protein processing and textured treatment, can solve problems such as easy slipping, insufficient muscle fiber feeling, and inability to uniformly melt and react, and achieve the effect of uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

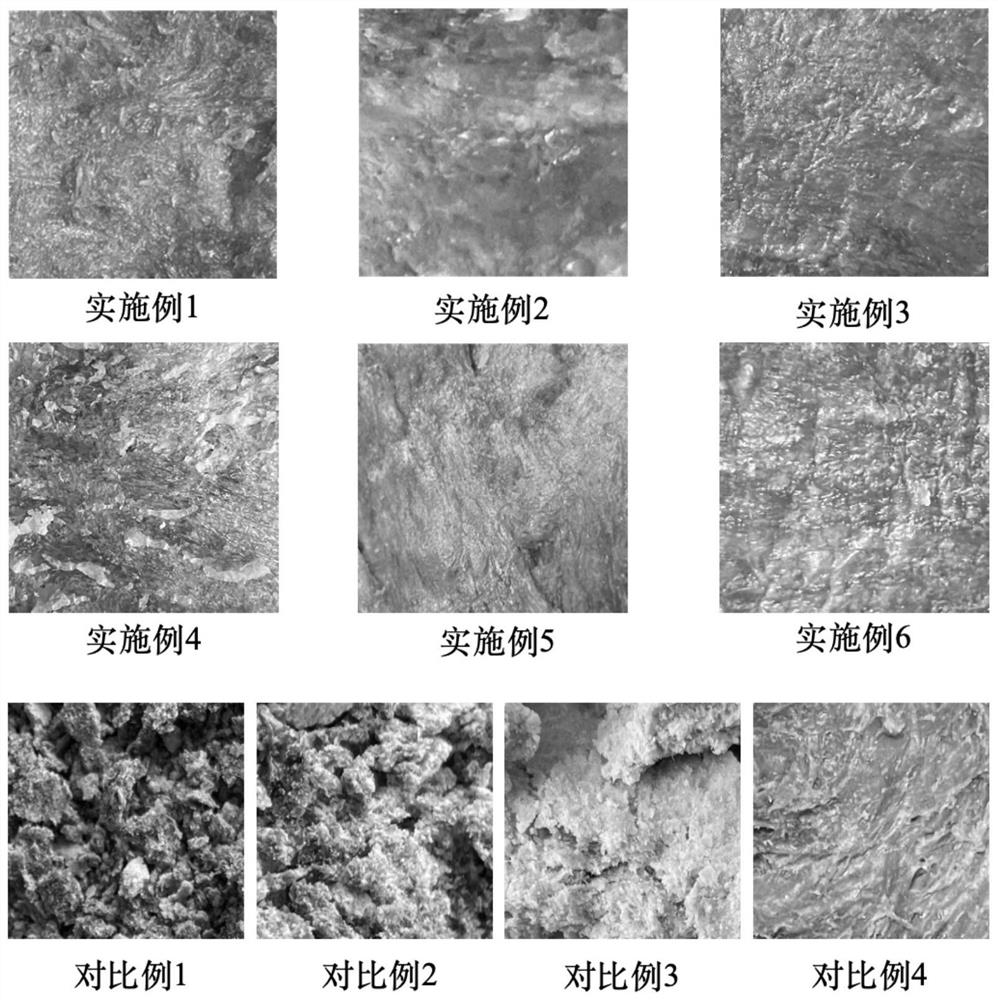

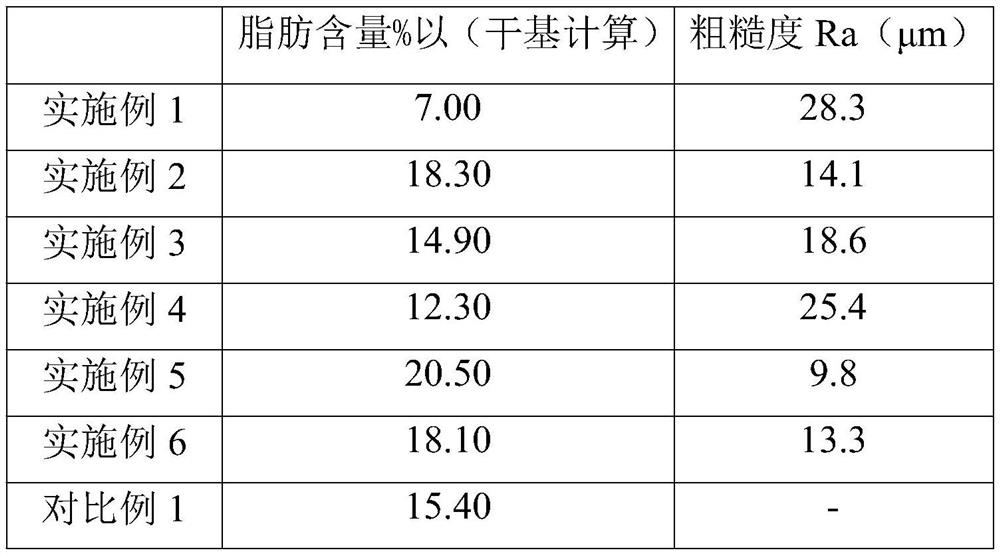

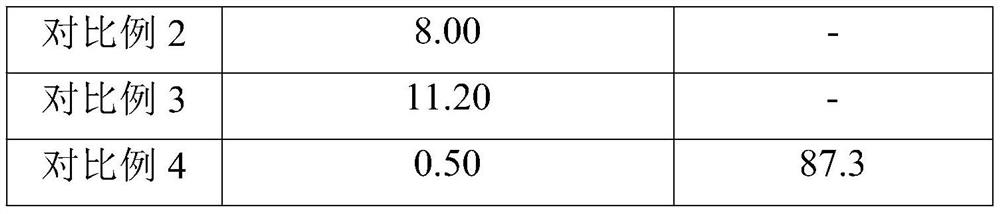

Examples

Embodiment 1

[0025] A method for extrusion processing of plant meat tissue protein, comprising the following steps:

[0026] (1) Raw material mixing 1: 4.8 kg of soybean protein isolate, 0.2 kg of peanut protein, 2 kg of coconut oil and 3 kg of water are added to the mixer and mixed evenly to obtain a mixed material 1, and the mixing speed of the mixer is 200 r / min , the mixing time is 2min;

[0027] (2) One-stage low-temperature extrusion: the mixed material 1 in step (1) is fed into a first-stage low-temperature single-screw extruder through a feeder for extrusion, and the materials are sequentially fed and mixed in the low-temperature single-screw extruder. , shear embedding and molding, and finally obtain protein meal; the feeding rate of the feeder is 60r / min, the temperature of the feeding and mixing section of the extruder conveying and mixing section is 50 °C, and the temperature of the shearing and embedding section is 100 °C. ℃, the temperature of the molding section is 90 ℃, th...

Embodiment 2

[0031] A method for extrusion processing of plant meat tissue protein, comprising the following steps:

[0032] (1) Raw material mixing 1: 4.6 kg of soybean protein isolate, 0.4 kg of gluten, 2 kg of coconut oil and 3 kg of water are added to the mixer and mixed evenly to obtain a mixed material 1, and the mixing rate of the mixer is 300r / min, the mixing time is 3min;

[0033] (2) One-stage low-temperature extrusion: the mixed material 1 in step (1) is fed into a first-stage low-temperature single-screw extruder through a feeder for extrusion, and the materials are sequentially fed and mixed in the low-temperature single-screw extruder. , shear embedding and molding, and finally obtain protein meal; the feeding rate of the feeder is 90r / min, the temperature of the feeding and mixing section of the extruder conveying and mixing section is 60 °C, and the temperature of the shearing and embedding section is 110 °C. ℃, the temperature of the molding section is 100 ℃, the speed o...

Embodiment 3

[0037] A method for extrusion processing of plant meat tissue protein, comprising the following steps:

[0038] (1) Raw material mixing 1: 5kg of pea protein, 1.4kg of coconut oil, 0.4kg of palm oil, 0.2kg of walnut oil and 3kg of water are added to the mixer and mixed evenly to obtain a mixed material 1, and the mixing rate of the mixer is is 220r / min, and the mixing time is 2min;

[0039] (2) One-stage low-temperature extrusion: the mixed material 1 in step (1) is fed into a first-stage low-temperature single-screw extruder through a feeder for extrusion, and the materials are sequentially fed and mixed in the low-temperature single-screw extruder. , shear embedding and molding, and finally obtain protein meal; the feeding rate of the feeder is 66r / min, the temperature of the feeding and mixing section of the extruder conveying and mixing section is 55 ℃, and the temperature of the shearing and embedding section is 105 ℃, the temperature of the molding section is 95 ℃, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com