Carboxyethyl chitosan derivative/oxidized konjac mannan injectable hydrogel as well as preparation method and application thereof

A technology of konjac mannan and carboxyethyl chitosan, which is applied in application, surgery, surgical adhesives, etc., can solve the problems of limited application and poor water solubility, and achieve excellent tissue adhesion, prevent tissue adhesion, and excellent Effect of anti-infective properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A carboxyethyl chitosan derivative / oxidized konjac mannan injectable hydrogel is carried out according to the following steps:

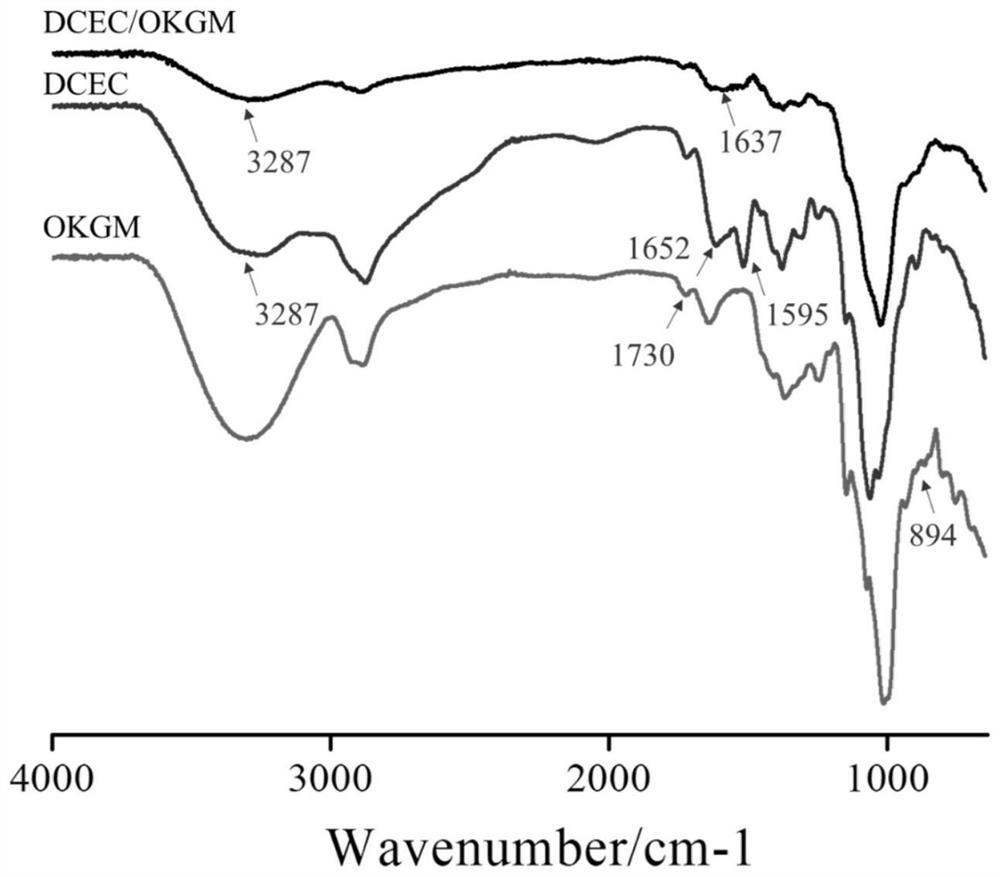

[0031] S1: Dissolve 0.4g chitosan powder (2.5mmol) in 20ml deionized water containing 3.4ml acrylic acid (5mmol) solution, stir until the solution is clear and transparent and add 0.114ml 2-dodecyl acrylate (0.4mmol) , after 3 days of reaction at 40°C, the reaction solution was put into a dialysis bag (MW=8000), firstly dialyzed with absolute ethanol for 3 days, then with deionized water for 3 days, and finally freeze-dried to obtain dodecyl-modified carboxyethyl Chitosan (DCEC);

[0032] S2: Dissolve 1 g of konjac mannan (6.25 mmol) in 100 ml of water, add 0.67 g of sodium periodate (3.125 mmol), react for 5 h at 25°C in the dark, add 1.5 ml of ethylene glycol, and continue the reaction for 1 h. The solution was put into a dialysis bag (MW=8000), and lyophilized after 3 days of deionized water dialysis to obtain oxidized konjac mannan (OKGM)...

Embodiment 2

[0042] A carboxyethyl chitosan derivative / oxidized konjac mannan injectable hydrogel is carried out according to the following steps:

[0043] S1: Dissolve 0.4g chitosan powder (2.5mmol) in 20ml deionized water containing 3.4ml acrylic acid (5mmol) solution, stir until the solution is clear and transparent, add 0.085ml 2-dodecyl acrylate (0.31mmol) After 3 days of reaction at 40°C, the reaction solution was put into a dialysis bag (MW=8000), firstly dialyzed with absolute ethanol for 3 days, then with deionized water for 3 days, and finally freeze-dried to obtain dodecyl-modified carboxyethyl Chitosan (DCEC);

[0044] S2: Dissolve 1 g of konjac mannan (6.25 mmol) in 100 ml of water, add 0.67 g of sodium periodate (3.125 mmol), add 1.5 ml of ethylene glycol after reacting for 5 h at 25°C in the dark, and continue the reaction for 1 h. The solution was put into a dialysis bag (MW=8000), and lyophilized after 3 days of deionized water dialysis to obtain oxidized konjac mannan (O...

Embodiment 3

[0048] A carboxyethyl chitosan derivative / oxidized konjac mannan injectable hydrogel is carried out according to the following steps:

[0049] S1: Dissolve 0.4g chitosan powder (2.5mmol) in 20ml deionized water containing 3.4ml acrylic acid (5mmol) solution, stir until the solution is clear and transparent and add 0.114ml 2-dodecyl acrylate (0.4mmol) , after 3 days of reaction at 40°C, the reaction solution was put into a dialysis bag (MW=8000), firstly dialyzed with absolute ethanol for 3 days, then with deionized water for 3 days, and finally freeze-dried to obtain dodecyl-modified carboxyethyl Chitosan (DCEC);

[0050] S2: Dissolve 1 g of konjac mannan (6.25 mmol) in 100 ml of water, add 1.34 g of sodium periodate (6.25 mmol), react for 5 h at 25°C in the dark, add 1.5 ml of ethylene glycol, continue to react for 1 h and then react The solution was put into a dialysis bag (MW=8000), and lyophilized after 3 days of deionized water dialysis to obtain oxidized konjac mannan (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com