Preparation method and application of MOF/corn straw composite material and device

A corn stalk and composite material technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult recovery of MOF materials, difficult processing, poor operability, etc. Scale-up production, rich porosity, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A MOF / corn stover composite material:

[0059] a) pretreating the corn stalk, peeling the corn stalk, cutting into sections, washing with 1M dilute hydrochloric acid 3 times, then washing with water until neutral, and drying to obtain the pre-treated corn stalk;

[0060] b) 4 mmol ZrCl 4 , 4mmol terephthalic acid, 10mL glacial acetic acid are dissolved in 80mL N,N-dimethylformamide; Get 1g corn stover to be immersed in above-mentioned solution, pump / vacuum 3 times to make corn stover immersion saturated;

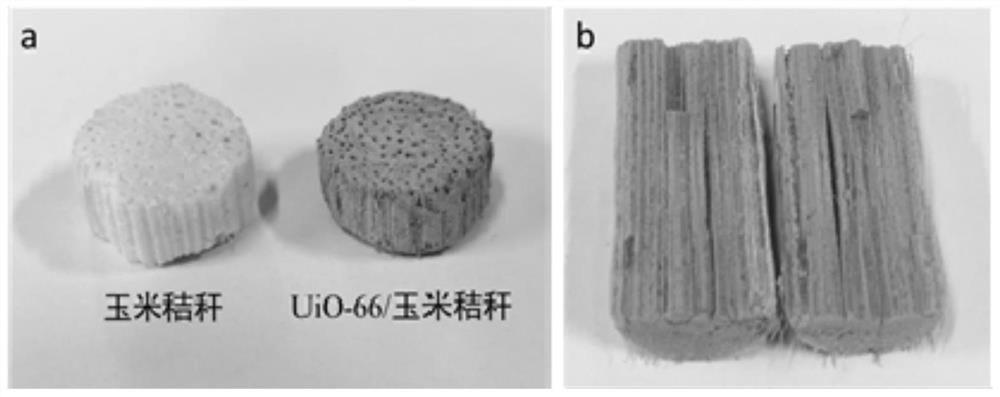

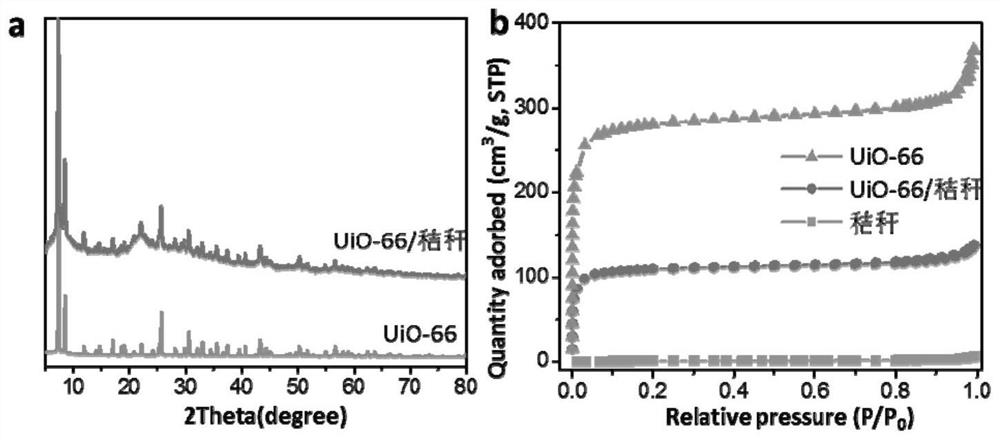

[0061] c) Transfer the straw filled with the MOF precursor solution to a hydrothermal kettle, raise the temperature to 120° C. for 24 hours; then wash the obtained product with DMF and water for several times, remove the remaining reactants, and dry to obtain the biomass with corn stalks. Structure of UiO-66 / straw composites. As shown in Figure 1, picture a is the photo of corn stalk and UiO-66 / corn stalk; picture b is the internal photo of UiO-66 / corn stalk. from ...

Embodiment 2

[0063] A MOF / corn stover composite material:

[0064] a) pretreating the corn stalk, peeling the corn stalk, cutting into sections, washing with 1M dilute hydrochloric acid 3 times, then washing with water to neutrality, drying, and obtaining the pre-treated corn stalk;

[0065] b) 2 mmol ZrCl 4 , 2mmol terephthalic acid, 5mL glacial acetic acid are dissolved in 80mL N,N-dimethylformamide; Get 1g corn stover to be immersed in above-mentioned solution, pump / de-vacuum 3 times to make corn stover immersion saturated;

[0066] c) Transfer the straw filled with the MOF precursor solution to a hydrothermal kettle, raise the temperature to 120° C. for 24 hours; then wash the obtained product with DMF and water several times to remove the remaining reactants, and dry to obtain a low-loading product. UiO-66 / straw composite.

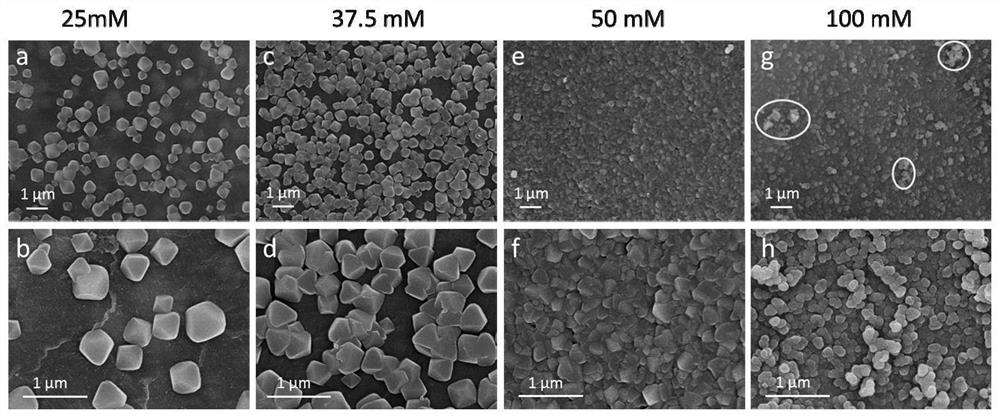

[0067] like figure 2 As shown in a-b, when the precursor concentration is low, the MOF particles are discretely distributed on the surface of the straw, and n...

Embodiment 3

[0069] A MOF / corn stover composite material:

[0070] a) pretreating the corn stalk, peeling the corn stalk, cutting into sections, washing with 1M dilute hydrochloric acid 3 times, then washing with water to neutrality, drying, and obtaining the pre-treated corn stalk;

[0071] b) 8 mmol ZrCl 4 , 8mmol terephthalic acid, 10mL glacial acetic acid are dissolved in 80mL N,N-dimethylformamide; Get 1g corn stover to be immersed in above-mentioned solution, pump / vacuum 3 times to make corn stover immersion saturated;

[0072] c) Transfer the straw filled with the MOF precursor solution to a hydrothermal kettle, raise the temperature to 120° C. for 24 hours; then wash the obtained product with DMF and water for several times, remove the remaining reactants, and dry to obtain a higher loading capacity. UiO-66 / straw composite.

[0073] like figure 2 As shown in a-b, excess MOF particles are freed from the MOF membrane at higher precursor concentrations.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com