Concrete performance improver and preparation method thereof

A technology of improver and concrete, which is applied in the preparation of the aforementioned concrete performance improver and the field of concrete performance improver, which can solve the problems of high raw material cost and high raw material price, and achieve the effect of simple operation, low cost and reduced raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the concrete performance improving agent in the present embodiment comprises the following steps in turn:

[0025] Step 1. Weigh each component according to weight ratio;

[0026] Step 2, take 55%~65% of the total amount of deionized water and place it in a container;

[0027] Step 3, add cellulose and sodium sulfite to the container, stir until completely dissolved;

[0028] Step 4, adding mixed alcohol solution, diethylene monoalcohol isopropanolamine, triethanolamine, modified wood calcium, and stirring until completely dissolved;

[0029] Step 5. Add defoamer and preservative to the container and stir evenly;

[0030] Step 6, adding the remaining ionized water into the container, that is, the concrete performance improving agent is prepared.

Embodiment 1

[0032] The concrete performance improving agent in this embodiment, calculated in 1000 parts, includes the following components by weight: 80 parts of mixed alcohol solution with a volume concentration of 80%, 10 parts of triethanolamine, and 10 parts of diethanol monoisopropanolamine , 10 parts of sodium sulfite, 1 part of cellulose, 1 part of modified wood calcium, 0.1 part of defoamer, 0.5 part of preservative and 887.4 parts of deionized water. The components of the mixed alcohol solution are: 52% glycerol, 16% diglycerol, 4% triacetylglycerol, 5% triglycerol and 20% water, and the rest are inevitable impurities.

[0033] Sample Preparation

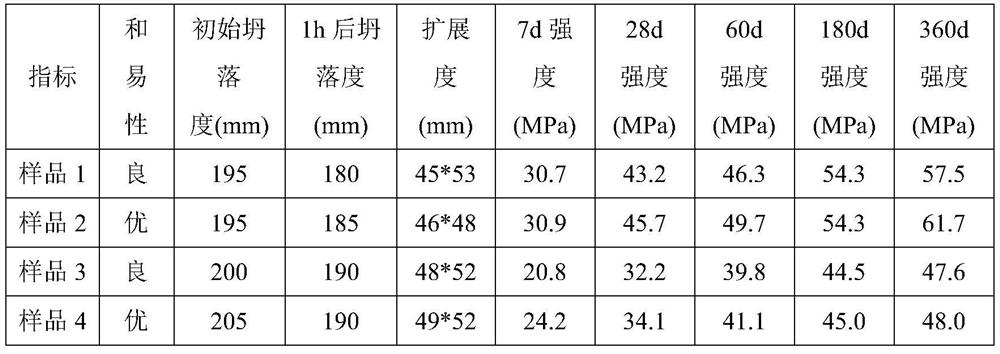

[0034] Each concrete sample was prepared according to Table 1 below. The specific components of the admixture are: slump-preserving polycarboxylic acid: water-reducing polycarboxylic acid: glucose sodium polycarboxylate = 42:50:8, and the specific components of the improver refer to Example 1. The unit of each component is kg.

[0...

Embodiment 2

[0043] The concrete performance improving agent in this embodiment, in 1000 parts, includes the following components by weight: 70 parts of mixed alcohol solution with a volume concentration of 85%, 5 parts of triethanolamine, and 5 parts of diethanol monoisopropanolamine , 5 parts of sodium sulfite, 5 parts of cellulose, 0.5 parts of modified wood calcium, 0.2 parts of defoamer, 0.3 parts of preservatives and 909 parts of deionized water. The components of the mixed alcohol solution are: 58% glycerol, 13% diglycerol, 6% triacetylglycerol, 3% triglycerol and 15% water, and the rest are inevitable impurities. The concrete performance improver in this example can significantly improve the slump, expansion, strength and workability of concrete when the amount of cement is reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com