Method for continuously refining dimethyl 2, 6-naphthalate

A technology of dimethyl naphthalate and xylene, which is applied in the field of continuous refining of dimethyl 2,6-naphthalate, can solve the problems of clogging of filter plates, deterioration of color and air pollution, etc., and achieve stable and smooth output. The effect of improving the material, yield and purity, and improving the operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] The obtained crude 2,6-NDA (purity 98.0%) and anhydrous methanol were added to the esterification reactor. The mass ratio of 2,6-NDA to methanol was 1:7.5. Under the action of catalyst sulfuric acid (8% wt) , the esterification reaction was carried out at 170° C. and 2.4MPa (gauge pressure), and the reaction was carried out for 5 hours. After the reaction was completed, after cooling, washing with deionized water and suction filtration, the obtained yellow flaky crystal was crude 2,6-NDC, the yield was 98.0%, the purity was 95.0%, and the chromaticity was 120.

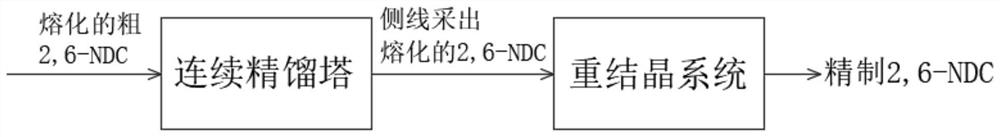

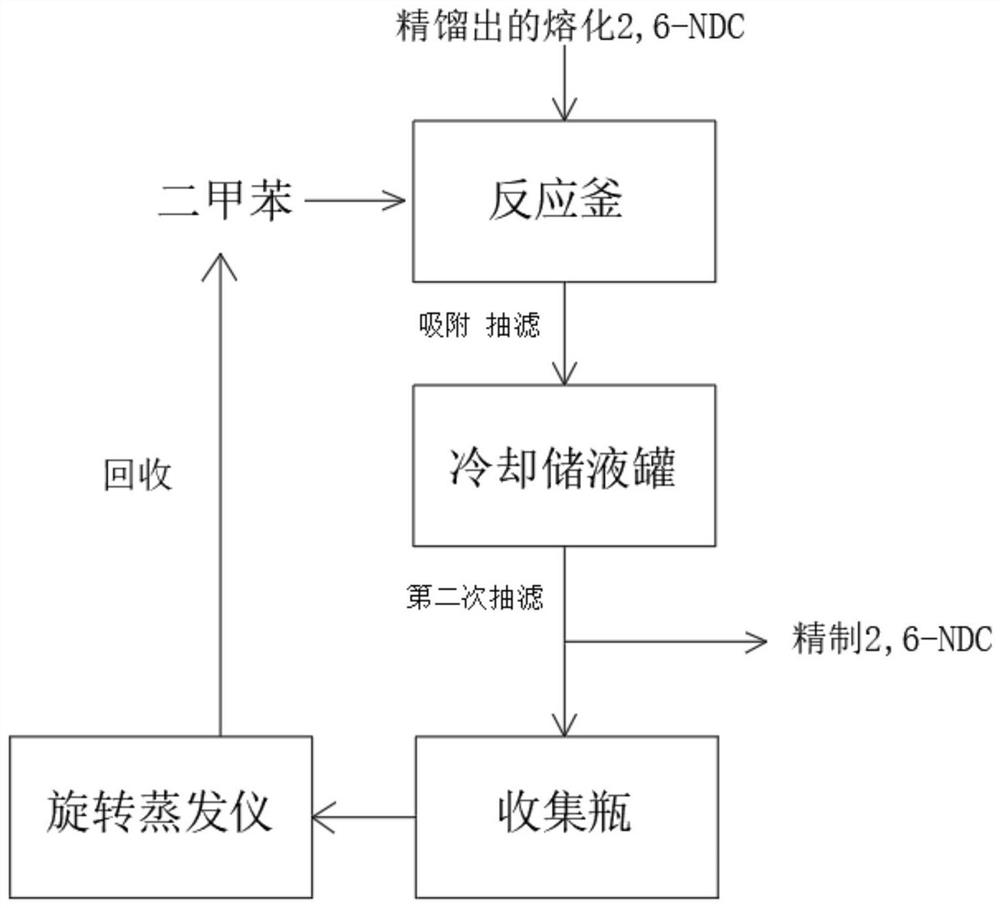

[0069] First, the crude 2,6-NDC in the feed storage tank is melted, and the feed is continuously pumped in the tower for continuous rectification. Each part of the rectification tower exposed to the air needs to be traced, and the trace temperature is 195 °C. The rectification is often carried out under reduced pressure, the operating pressure is 10 mbar, the temperature at the bottom of the column is 210-270 °C...

Embodiment 2

[0072] The obtained crude 2,6-NDA (purity 98.0%) and anhydrous methanol were added to the esterification reactor, the mass ratio of 2,6-NDA and methanol was 1:7.5, under the action of catalyst sulfuric acid (9% wt) , the esterification reaction was carried out at 160° C. and 2.2 MPa (gauge pressure) for 7 hours. After the reaction was completed, after cooling, washing with deionized water and suction filtration, the obtained yellow flaky crystal was crude 2,6-NDC, the yield was 97.0%, the purity was 95.0%, and the chromaticity was 120.

[0073] First, the crude 2,6-NDC in the feed storage tank is melted, and the feed is continuously pumped in the tower for continuous rectification. Each part of the rectification tower exposed to the air needs to be traced, and the trace temperature is 200°C. The rectification is often carried out under reduced pressure, the operating pressure is 12 mbar, the temperature at the bottom of the column is 210-270 °C, and the theoretical plate numbe...

Embodiment 3

[0076] The obtained crude 2,6-NDA (purity 98.0%) and anhydrous methanol were added to the esterification reactor. The mass ratio of 2,6-NDA to methanol was 1:7.5. Under the action of catalyst sulfuric acid (8% wt) , the esterification reaction was carried out at 160° C. and 2.2 MPa (gauge pressure) for 7 hours. After the reaction was completed, after cooling, washing with deionized water and suction filtration, the obtained yellow flaky crystal was crude 2,6-NDC, the yield was 97.0%, the purity was 95.0%, and the chromaticity was 120.

[0077] First, the crude 2,6-NDC in the feed storage tank is melted, and the feed is continuously pumped in the tower for continuous rectification. Each part of the rectification tower exposed to the air needs to be traced, and the trace temperature is 200°C. The rectification is often carried out under reduced pressure, the operating pressure is 15 mbar, the temperature at the bottom of the column is 210-270 °C, and the theoretical plate number...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com