Accelerator as well as application and preparation device thereof

A technology for preparing devices and accelerators, applied in biochemical cleaning devices, enzymology/microbiology devices, gas production bioreactors, etc., can solve problems such as long fermentation time, improve gas production rate, reduce maintenance costs, Energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

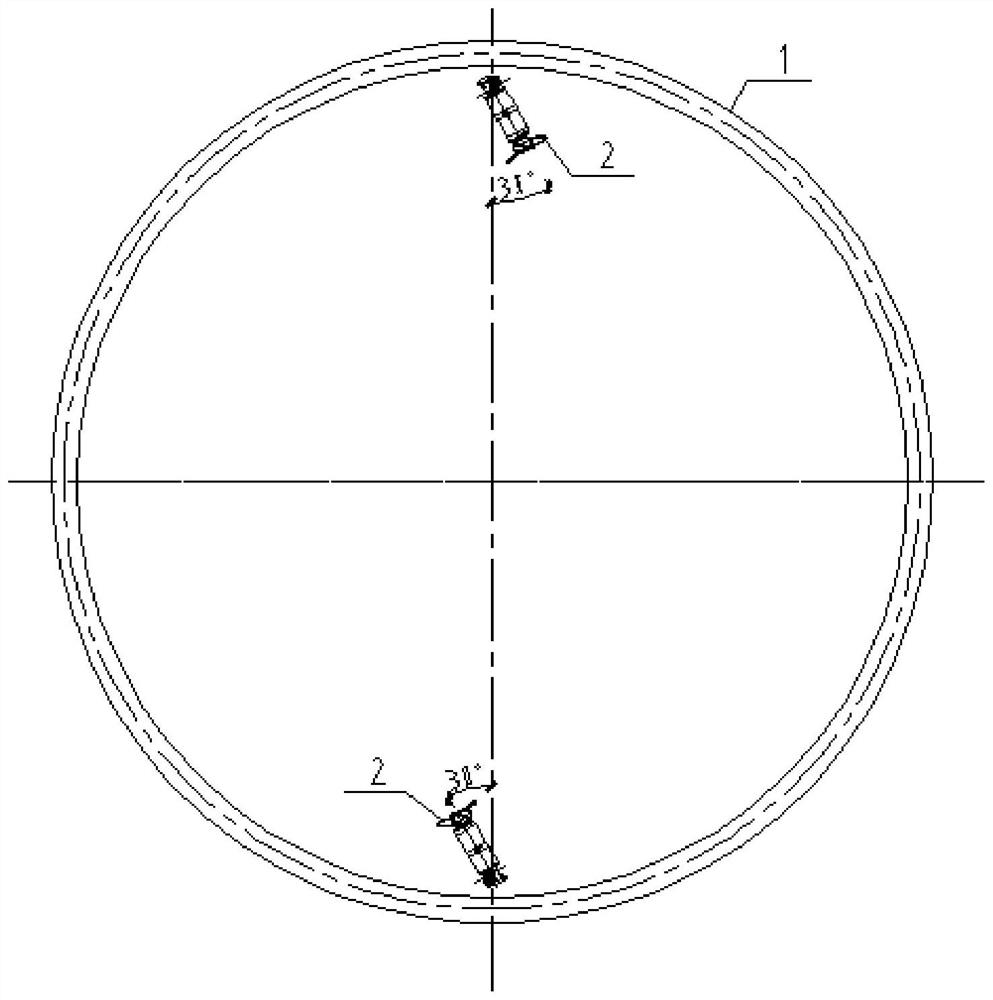

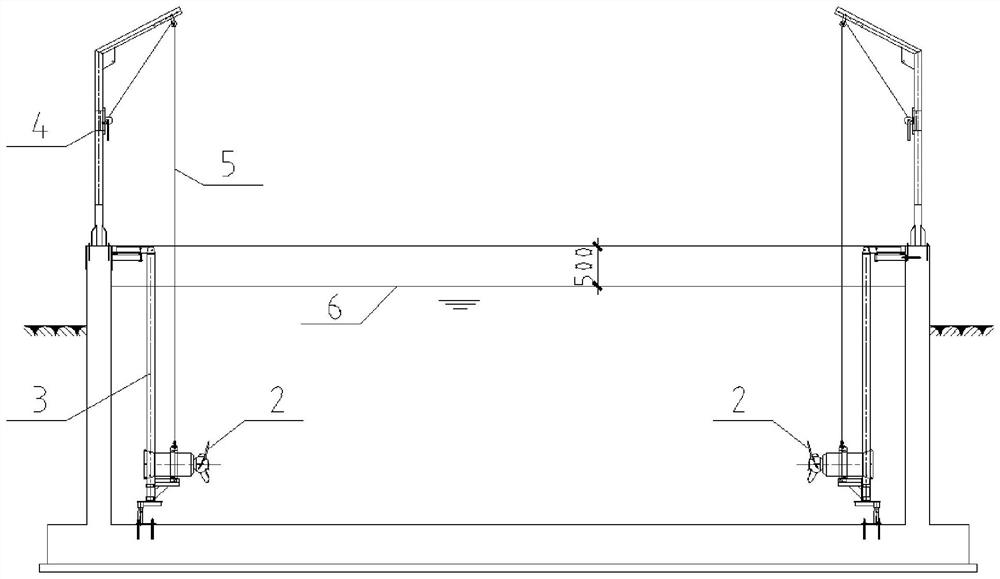

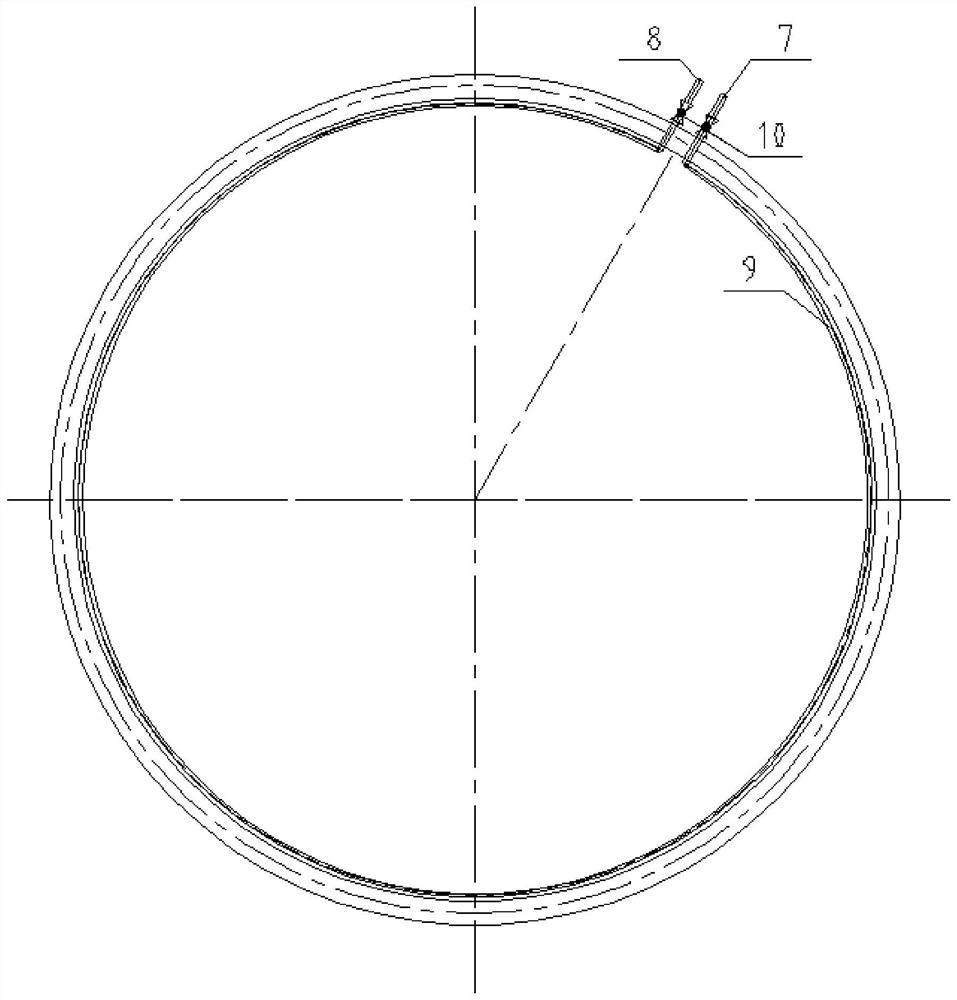

[0047] This embodiment provides a preparation device, refer to figure 1 , Figure 4 and Figure 7 , including hydrolysis tank 1, heating coil 9 and aeration mechanism. There is a stirring mechanism in the hydrolysis tank 1, and the stirring mechanism is suitable for stirring the materials in the hydrolysis tank 1; the heating coil 9 is arranged circumferentially along the side wall of the hydrolysis tank 1; the aeration mechanism is arranged in the hydrolysis tank 1 and is suitable for the hydrolysis tank 1. Enter gas into tank 1.

[0048] The above-mentioned hydrolysis tank 1 is provided with an elevation mark 6 at a distance of 500 mm from the top of the hydrolysis tank 1. During use, the material is put into the hydrolysis tank 1, so that the material does not exceed the elevation mark 6 of the hydrolysis tank 1, and the stirring mechanism is started to carry out the material. Stir, and heat the material in the hydrolysis tank 1 through the heating coil 9, and the aerati...

Embodiment 2

[0064] This embodiment provides a kind of accelerator, which comprises by weight: 50 parts of biogas slurry, 40 parts of cow dung, 3 parts of cellulase, 5 parts of corn stover, 1 part of corn gluten, and 1 part of industrial glucose;

[0065] The accelerator is prepared using the preparation device provided in Example 1, and the preparation method includes the following preparation steps:

[0066] S1. Put biogas slurry, cow dung, cellulase, corn stover, corn gluten and industrial glucose into the hydrolysis tank and mix them evenly;

[0067] S2. First use a submersible agitator to stir for 5 minutes, then turn on the roots blower to input gas into the hydrolysis tank, so that the dissolved oxygen concentration in the material is 0.5mg / L, and then set the submersible agitator to stir for 5 minutes per hour; keep the heating coil always Convey hot water to heat the material, keep the temperature of the material at about 38 °C, and continue to hydrolyze for 72 hours.

Embodiment 3

[0069] This embodiment provides a kind of accelerator, which comprises by weight: 60 parts of biogas slurry, 30 parts of cow dung, 3 parts of cellulase, 5 parts of corn stover, 1 part of corn gluten, and 1 part of industrial glucose;

[0070] The accelerator is prepared using the preparation device provided in Example 1, and the preparation method includes the following preparation steps:

[0071] S1. Put biogas slurry, cow dung, cellulase, corn stover, corn gluten and industrial glucose into the hydrolysis tank and mix them evenly;

[0072] S2. First use a submersible agitator to stir for 5 minutes, then turn on the roots blower to input gas into the hydrolysis tank, so that the dissolved oxygen concentration in the material is 0.5mg / L, and then set the submersible agitator to stir for 5 minutes per hour; keep the heating coil always Convey hot water to heat the material, keep the temperature of the material at about 38 °C, and continue to hydrolyze for 72 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com