Neutral semi-water-based cleaning agent for high-performance electronic product printed board assembly piece, preparation method and application thereof

A technology for electronic products and printed boards, which is applied in the field of neutral semi-water-based cleaning agents for printed board assemblies of high-performance electronic products and its preparation. Achieve excellent high and low temperature stability, safe transportation and storage, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the above-mentioned high-performance electronic product printed board assembly neutral semi-water-based cleaning agent, the steps are as follows:

[0045] A. Weigh glycol ether ester solvent, aliphatic dihydric alcohol, accelerator, acetylene glycol active agent, benzotriazole derivative, hydroxycarboxylic acid and DI water according to the mass ratio;

[0046] B. At room temperature, add the above raw materials into the stirring tank, start stirring, the speed is 100-300r / min, and the time is 30-60min. After mixing evenly, the neutral semi-water of the high-performance electronic product printed board assembly is obtained. base cleaner.

[0047] Application of the above-mentioned neutral semi-water-based cleaning agent for printed board assemblies of high-performance electronic products in the cleaning of printed boards of electronic products.

[0048] The method for cleaning printed board assemblies of high-performance electronic products us...

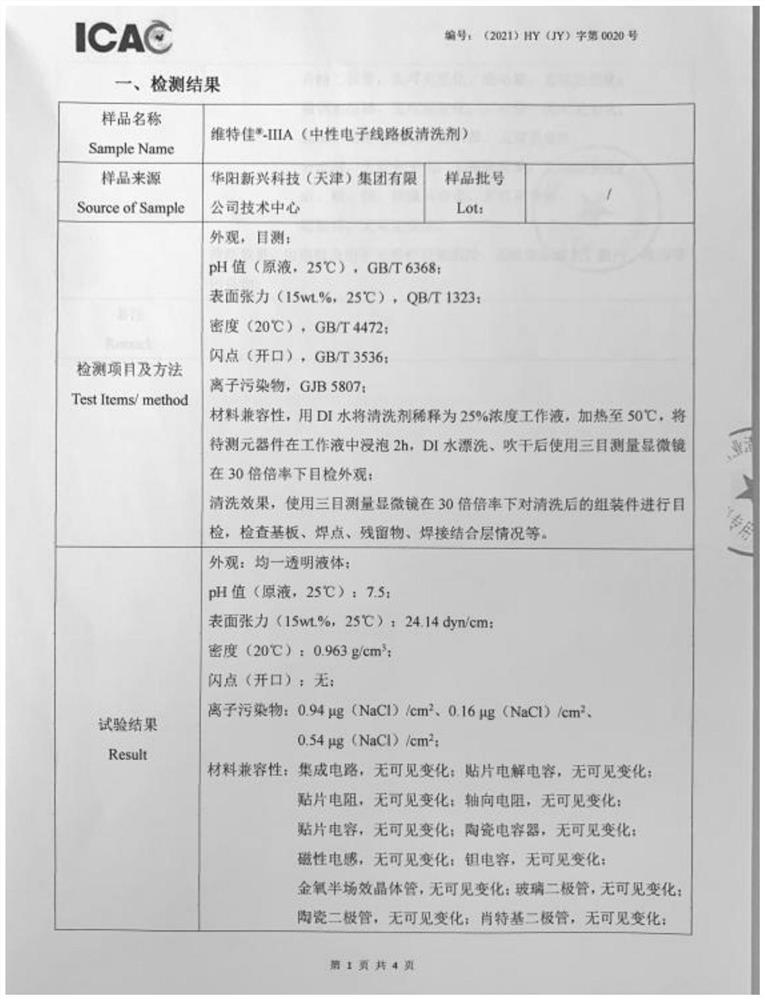

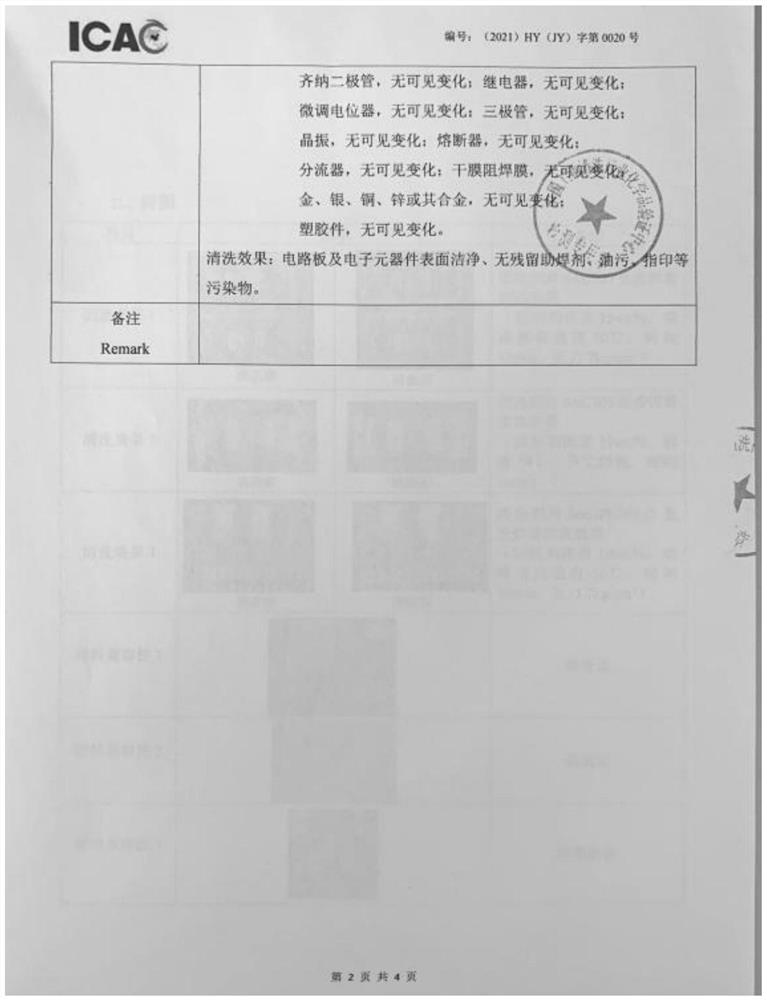

Embodiment 1

[0052] A neutral semi-water-based cleaning agent for printed board assemblies of high-performance electronic products, its raw material composition and weight percentage are:

[0053] Propylene glycol methyl ether acetate 45%, 2-methyl-2,4-pentanediol 25%, accelerator 10%, tetramethyldecynediol 8%, benzotriazole derivatives 0.5%, DL- Hydroxysuccinic acid 1%, DI water balance.

[0054] The preparation method steps of the above-mentioned high-performance electronic product printed board assembly neutral semi-water-based cleaning agent are as follows:

[0055] Weigh propylene glycol methyl ether acetate, 2-methyl-2,4-pentanediol, accelerator, tetramethyldecynediol, benzotriazole derivatives, DL-hydroxysuccinic acid according to the mass ratio and DI water; at room temperature, add the above-mentioned raw materials into the stirring tank, start the stirring, the rotation speed is 200r / min, and the time is 45min. Agent, cleaning agent pH value (stock solution, 25 ° C) = 7.50.

...

Embodiment 2

[0065] A neutral semi-water-based cleaning agent for printed board assemblies of high-performance electronic products, its composition and weight percentage are:

[0066] Dipropylene glycol methyl ether acetate 40%, 1,2-hexanediol 20%, accelerator 12%, dimethyloctynediol 6%, benzotriazole derivatives 0.5%, 2,3-dihydroxy Succinic acid 1.5%, DI water balance.

[0067] The preparation method steps of the above-mentioned high-performance electronic product printed board assembly neutral semi-water-based cleaning agent are as follows:

[0068] Weigh dipropylene glycol methyl ether acetate, 1,2-hexanediol, accelerator, dimethyloctynediol, benzotriazole derivatives, 2,3-dihydroxysuccinic acid and DI water; at room temperature, add the above-mentioned raw materials into the stirring tank, start the stirring, the speed is 200r / min, and the time is 45min. After mixing evenly, a neutral semi-water-based cleaning agent for printed board assemblies of high-performance electronic products ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com