Platinum film with high resistance temperature coefficient and preparation method thereof

A temperature coefficient and thin film preparation technology, applied in the field of platinum thin films, can solve the problems affecting the response performance of platinum thin film resistance temperature sensors, the failure of platinum thin film resistance temperature sensors, and the decrease of resistance temperature coefficient, achieving excellent high temperature stability and weakening the agglomeration effect. , the effect of high temperature coefficient of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] On the other hand, the present invention provides a preparation method of the above-mentioned platinum thin film, comprising the following steps:

[0066] S1. Provide a ceramic substrate, and deposit an oxygen-containing platinum film on the ceramic substrate.

[0067] S2, heat-treating the above-mentioned thin film to cause thermal decomposition, agglomeration and solid-state dehumidification of the oxygen-containing platinum thin film.

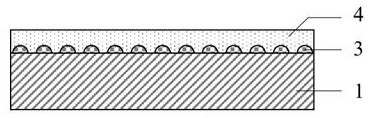

[0068] S3. Continue to deposit a metal platinum film on the above-mentioned film.

[0069] S4, heat-treating the above-mentioned thin film to obtain the desired platinum thin film.

[0070] S5. The above steps S1 and S2 can be repeated, and the steps S1, S2, S3 and S4 can be repeated until the desired platinum thin film is obtained.

[0071] In another aspect, the present invention provides another method for preparing the above-mentioned platinum thin film, comprising the following steps:

[0072] S1. Provide a ceramic substrate, ...

Embodiment 1

[0080] The present embodiment provides a method for preparing a platinum thin film with high temperature coefficient of resistance and excellent high temperature stability, comprising the following steps:

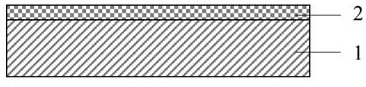

[0081] S1. Provide a ceramic substrate 1, and deposit a layer of oxygen-containing platinum film 2 on the ceramic substrate, such as figure 1 shown.

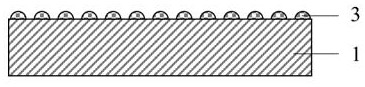

[0082] S2, heat treatment of the oxygen-containing platinum thin film 2, so that the oxygen-containing platinum thin film undergoes thermal decomposition, agglomeration and solid-state dehumidification to obtain a thin film 3, such as figure 2 shown. In this step, the metal platinum precipitated when the oxygen-containing platinum film is thermally decomposed will also undergo agglomeration and solid-state dehumidification during the heat treatment process. The agglomeration and solid-state dehumidification process has a certain selection effect. Absorbing" and "merging" platinum that has poor adhesion to the substrate, an...

Embodiment 2

[0086] This embodiment provides another method for preparing a platinum thin film with high temperature coefficient of resistance and excellent high temperature stability, comprising the following steps:

[0087] S1. Provide a ceramic substrate 1, and deposit a layer of oxygen-containing platinum film 2 on the ceramic substrate, such as Figure 5 shown.

[0088] S2, deposit a layer of metal platinum film 4 on the above-mentioned oxygen-containing platinum film 2, such as Image 6 shown.

[0089] S3, heat treatment of the oxygen-containing platinum film 2 and the metal platinum film 4 to obtain a platinum film with high temperature coefficient of resistance and excellent high temperature stability, such as Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com