Method for analyzing reinforcing effect of fibers on compression toughness of tailing cemented filling body

A technology of cemented filling and analysis method, which is used in the application of stable tension/pressure to test the strength of materials and the preparation of samples for testing. The tailings cemented the backfill peak and ductile deformation stage and other problems to achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The fiber tailings cemented backfill sample of this embodiment is composed of tailings, cement, and fibers. The tailings are selected from the tailings dam of a gold mine in Henan, the cement is composite Portland cement codenamed P.C32.5, and the fibers are glass fiber, polyacrylonitrile fiber, glass fiber and polyacrylonitrile fiber mixed fiber three. kind.

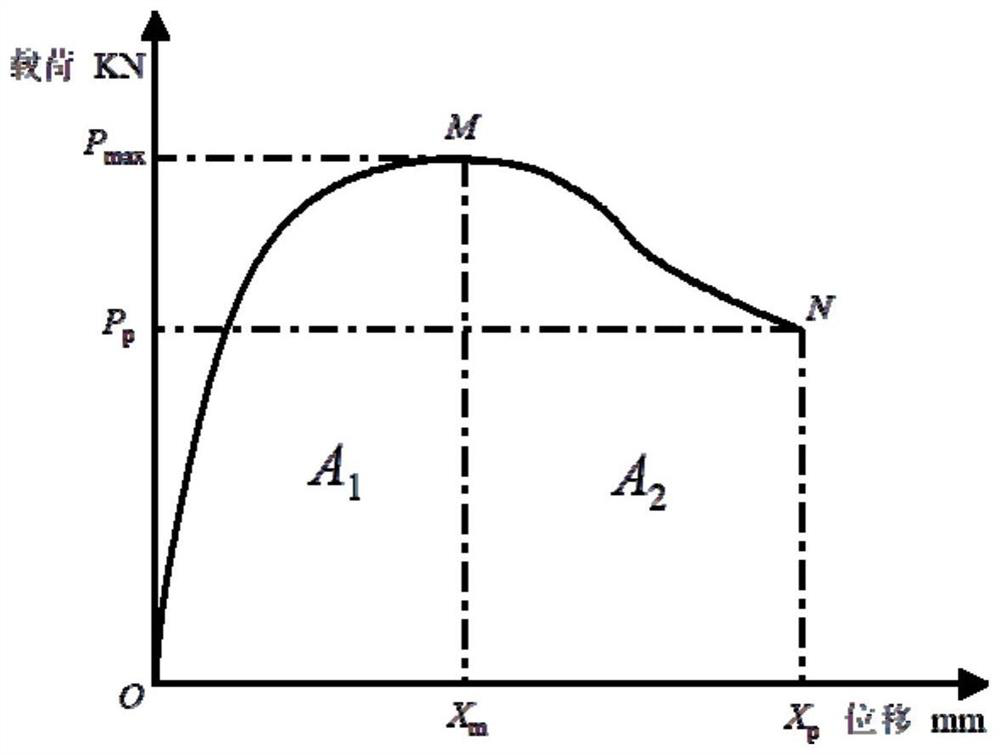

[0024] The analysis method for the enhancement effect of fiber on the compressive toughness of tailings cemented backfill includes the following steps:

[0025] Step 1. Make tailings cemented backfill specimens;

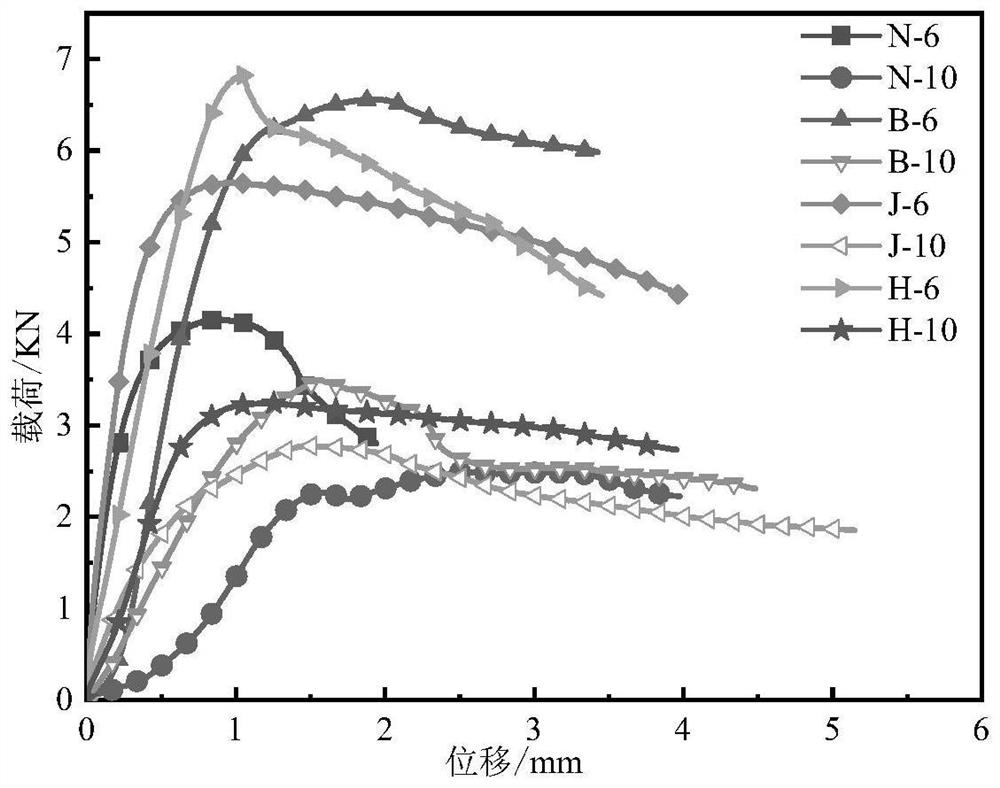

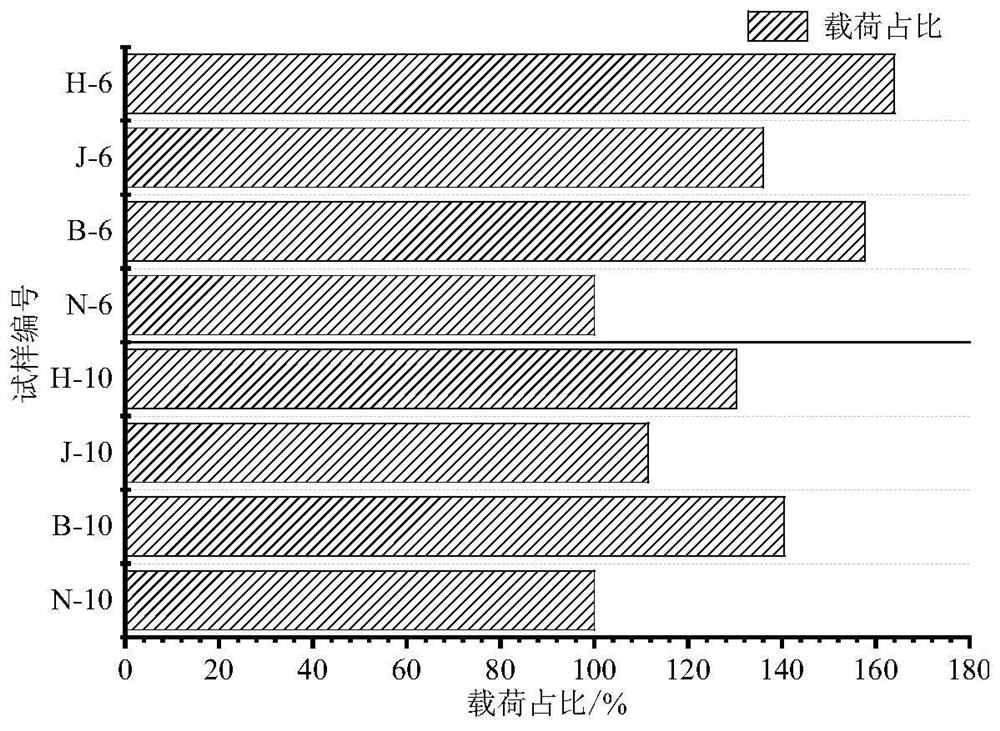

[0026] The mass concentration (solid concentration) of the tailings cemented backfill body is 68%, and the ratio of lime to sand is 1:6, respectively to make the non-fiber tailings cemented backfill body (specimen number: N-6), glass fiber tailings cemented backfill body Body (B-6), polyacrylonitrile fiber tailings cemented backfill (J-6), glass fiber and polyacrylonitrile mixed fiber tailings cemente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com