Preparation method of aerosol spraying process conductive silver paste for electronic circuit

A technology of conductive silver paste and electronic circuit, which is applied in the direction of cable/conductor manufacturing, circuit, conductive material dispersed in non-conductive inorganic materials, etc., can solve problems such as gas atomization, and achieve the effect of high practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

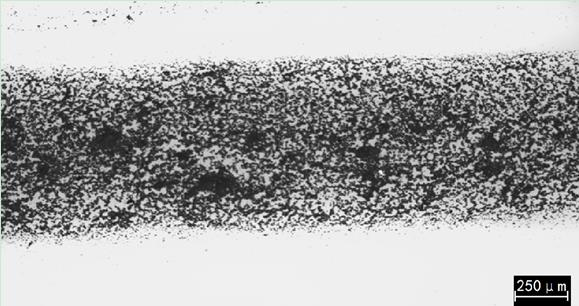

Image

Examples

Embodiment 1

[0021] A preparation method of conductive silver paste by aerosol spraying process for electronic circuits, comprising the following steps:

[0022] Step 1: Mix a certain proportion of anti-settling agent, coupling agent, surfactant, diluent and solvent to make organic additives, and take quantitative light-like spherical hollow structure silver powder and flake silver powder for later use; The mass percentage of each raw material is 10% of anti-settling agent, 28% of coupling agent, 32% of surfactant, 10% of diluent and 20% of solvent; the anti-settling agent is specifically polyamide wax, and the coupling agent is specifically KH- 570 silane coupling agent, the surfactant is a mixture of soybean lecithin and bromopalm trimethylammonium, the mass ratio of soybean lecithin and bromopalm trimethylammonium in the surfactant is 9:1, and the diluent is A6360 , the solvent is specifically solvent ECS; the mass ratio of flake silver powder and light-weight spherical-like hollow stru...

Embodiment 2

[0026] A preparation method of conductive silver paste by aerosol spraying process for electronic circuits, comprising the following steps:

[0027] Step 1: Mix a certain proportion of anti-settling agent, coupling agent, surfactant, diluent and solvent to make organic additives, and take quantitative light-like spherical hollow structure silver powder and flake silver powder for later use; The mass percentage of each raw material is 13% of anti-settling agent, 30% of coupling agent, 35% of surfactant, 12% of diluent and 10% of solvent; the anti-settling agent is specifically polyamide wax, and the coupling agent is specifically KH- 570 silane coupling agent, the surfactant is a mixture of soybean lecithin and bromopalm trimethylammonium, the mass ratio of soybean lecithin and bromopalm trimethylammonium in the surfactant is 9:1, and the diluent is A6360 , the solvent is specifically solvent ECS; the mass ratio of flake silver powder and light-weight spherical-like hollow stru...

Embodiment 3

[0031] A preparation method of conductive silver paste by aerosol spraying process for electronic circuits, comprising the following steps:

[0032] Step 1: Mix a certain proportion of anti-settling agent, coupling agent, surfactant, diluent and solvent to make organic additives, and take quantitative light-like spherical hollow structure silver powder and flake silver powder for later use; The mass percentage of each raw material is 12% of anti-settling agent, 29% of coupling agent, 33% of surfactant, 11% of diluent and 15% of solvent; the anti-settling agent is specifically polyamide wax, and the coupling agent is specifically KH- 570 silane coupling agent, the surfactant is a mixture of soybean lecithin and bromopalm trimethylammonium, the mass ratio of soybean lecithin and bromopalm trimethylammonium in the surfactant is 9:1, and the diluent is A6360 , the solvent is specifically solvent ECS; the mass ratio of flake silver powder and light-weight spherical-like hollow stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com