Waste tire rubber powder modified composite foundation bed structure based on high-speed rail roadbed strengthening layer

A high-speed railway base and waste tire rubber technology, which is applied to roads, ballast layers, solid waste management, etc., can solve the problems of unfavorable stress state of the bottom surface of the cement-stabilized gravel base, uncoordinated layer-to-layer deformation, and low stiffness of the roadbed. , to achieve the effects of weakening the occurrence of frost heaving and thawing deformation, increasing interlayer shear force, and relieving stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

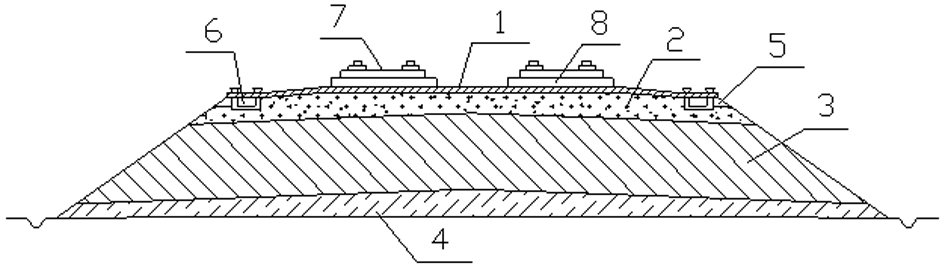

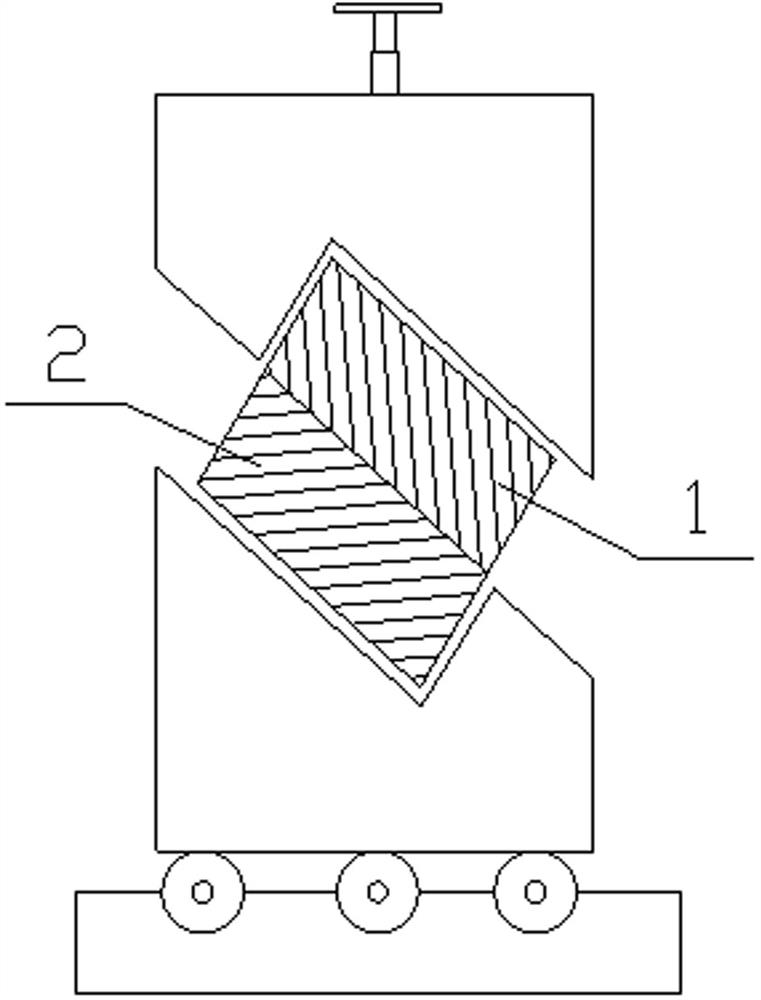

[0023] The invention discloses a waste tire rubber powder modified composite bed structure based on a high-speed railway base reinforcing layer, such as figure 1 As shown in the figure, the reinforcement layer 1 and the modified water stabilization layer 2 are arranged in sequence from top to bottom and respectively added with waste tire rubber powder, and the corresponding surfaces of the reinforcement layer 1 and the modified water stabilization layer 2 are combined with each other, The track is arranged on the reinforcement layer 1 , the modified water stabilization layer 2 is located on the bottom layer 3 of the base bed, and the bottom layer 3 of the base bed is located on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com