Flexible strain sensor based on vertical graphene and preparation method thereof

A strain sensor and graphene technology, applied in the field of wearable flexible sensors, can solve problems such as metal residues, polluting the environment, and affecting sensor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0031] The preparation method of the flexible strain sensor based on vertical graphene according to the present invention, the specific steps are as follows:

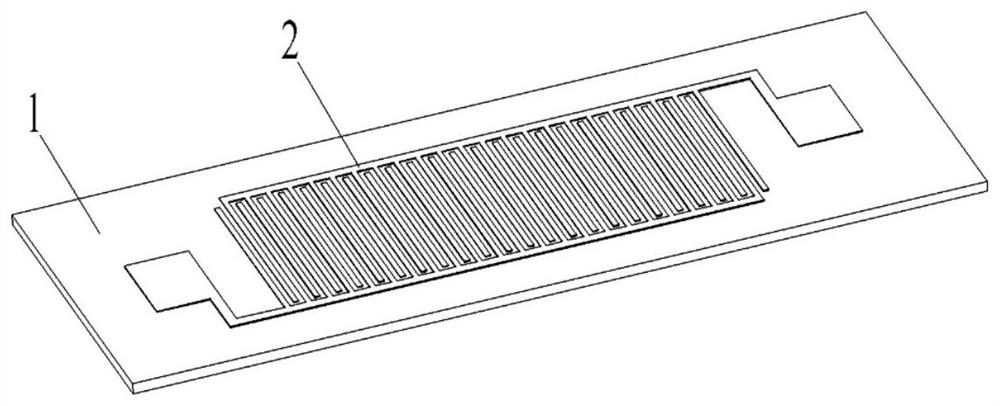

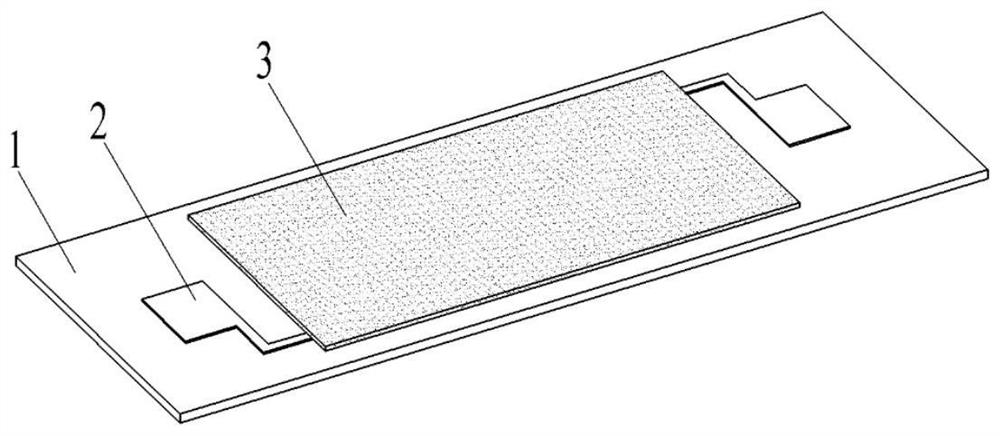

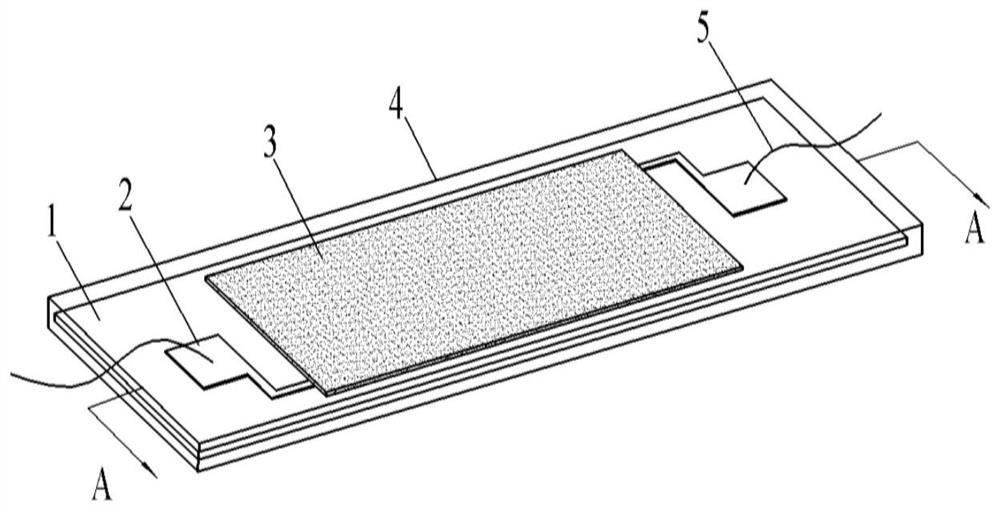

[0032] 1) Ultrasonic cleaning of flexible substrate-fluorine crystal mica sheet with SPM solution (hydrogen peroxide: concentrated sulfuric acid=1:4), acetone, isopropanol, deionized water, the thickness of the fluorine crystal mica sheet is 0.05mm, remove Metal and organic matter on the surface of the substrate, then purge the substrate with nitrogen gas, place the pre-cleaned stainless steel mask on the flexible substrate, put it in a magnetron sputtering apparatus, sputter for 10 minutes, and produce a line width of 500 μm , the interdigital electrode with interdigital spacing of 500 μm and thickness of 800 nm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| interdigital gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com