Antirust paint smearing device for ship engineering

An anti-rust paint and engineering technology, which is applied to the surface coating device, spray device, liquid spray device, etc., can solve the problems of high labor intensity, easy agglomeration, low work efficiency, etc. Avoid easy agglomeration and improve the effect of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

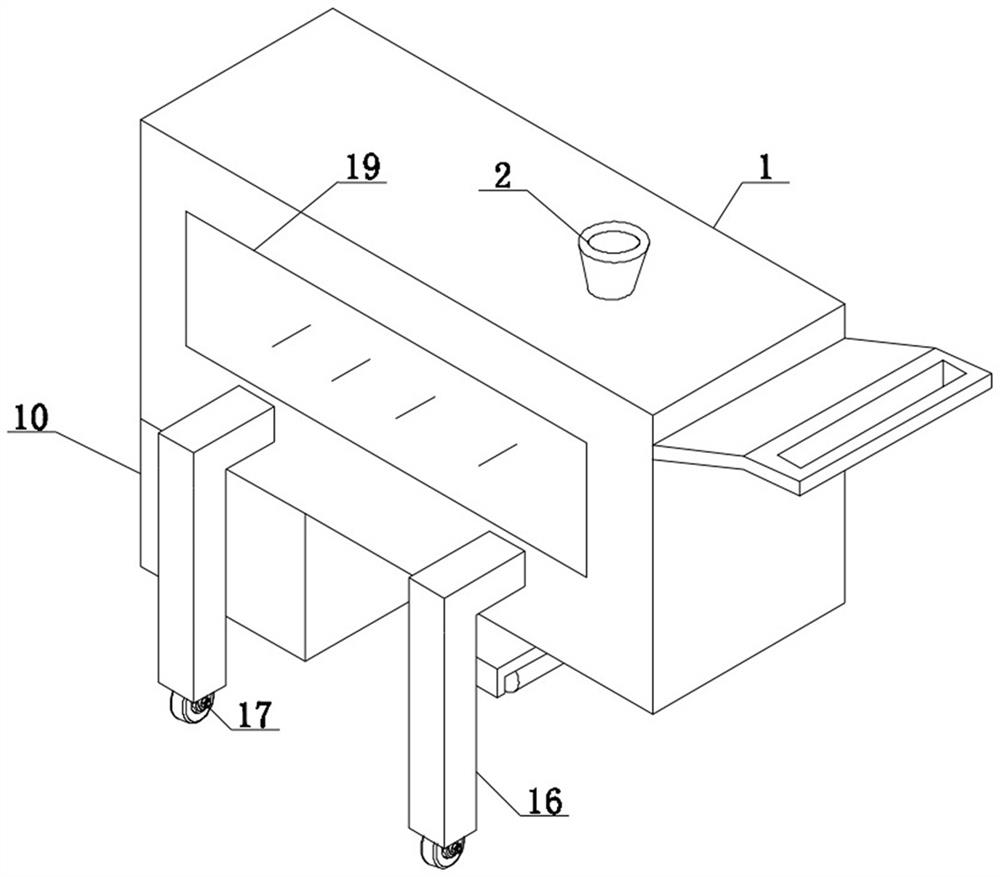

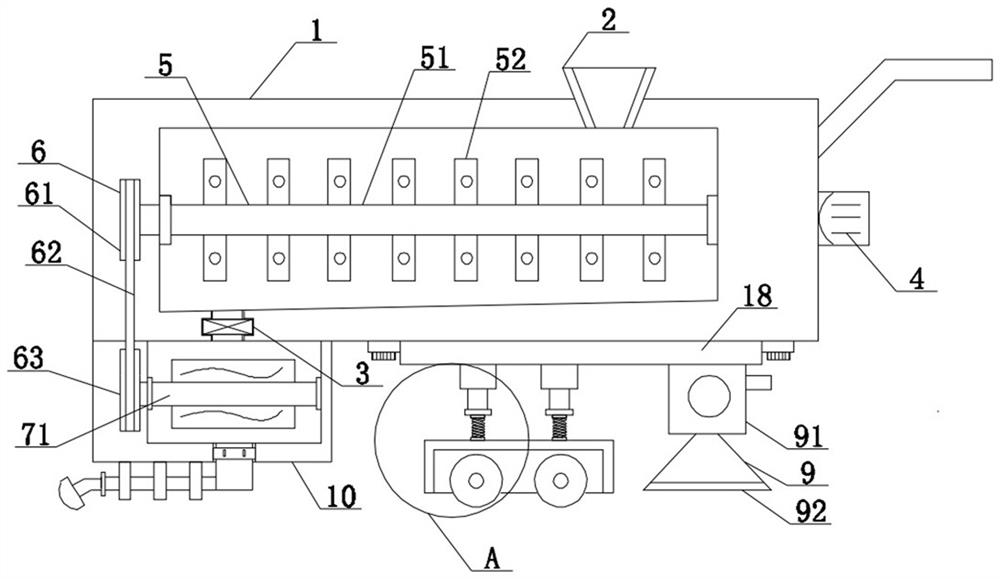

[0035] see Figure 1-7, an antirust paint coating device for marine engineering, comprising a base box 1, the right end of the base box 1 is fixedly connected with a motor 4, one side of the base box 1 is provided with a control panel, the base box 1 A feeding hopper 2 is fixedly connected to the upper end of the base box 1, a lowering box 10 is fixedly connected to the left side of the lower end of the base box 1, and a solenoid valve 3 is arranged between the lowering box 10 and the base box 1. The base box The inside of the base box 1 is provided with a first stirring component 5, the inside of the lowering box 10 is provided with a second stirring component 7, the left cavity of the base box 1 is provided with a linkage component 6, and the first stirring component 5 The linkage assembly 6 is connected with the second stirring assembly 7 in a driving manner. A positioning seat 18 is fixedly connected to the right side of the lower end of the base box 1 by screws. The othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com