Foam concrete stirring device for laboratory and sample preparation method

A foam concrete and mixing device technology, applied in the field of experimental instruments, can solve problems such as the adverse effects of holes, waste, and large foam voids, and achieve the effects of reducing loss or unevenness, quickly putting into use, and low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

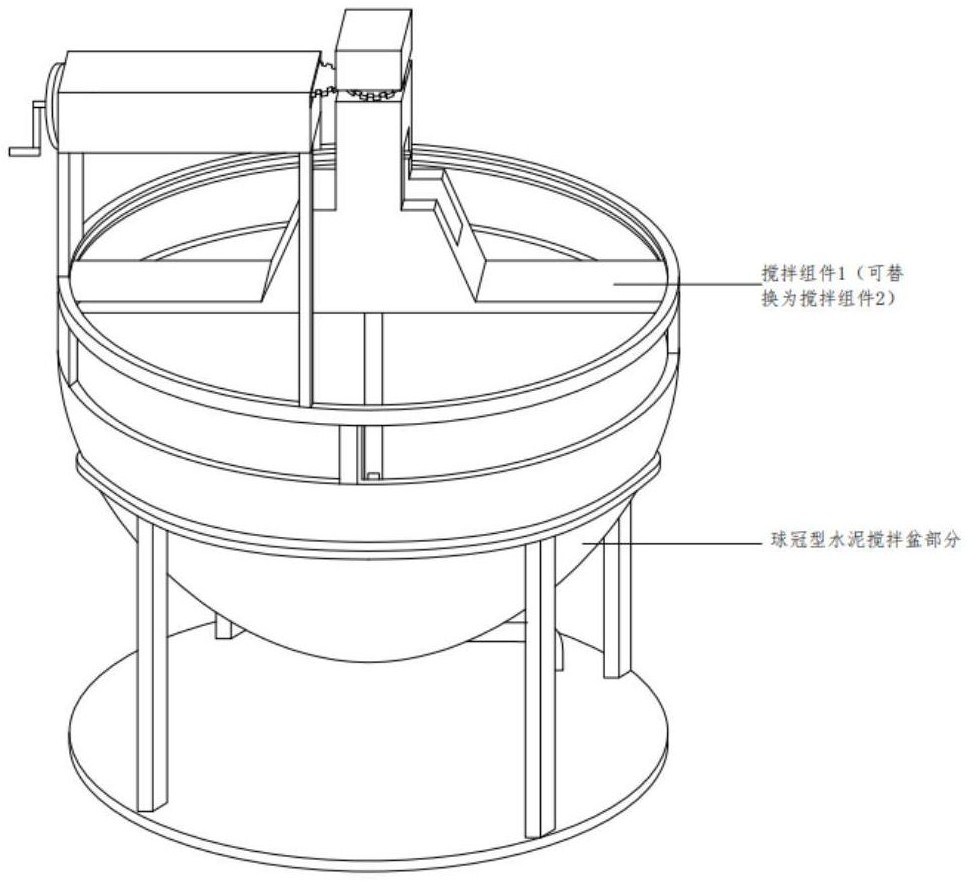

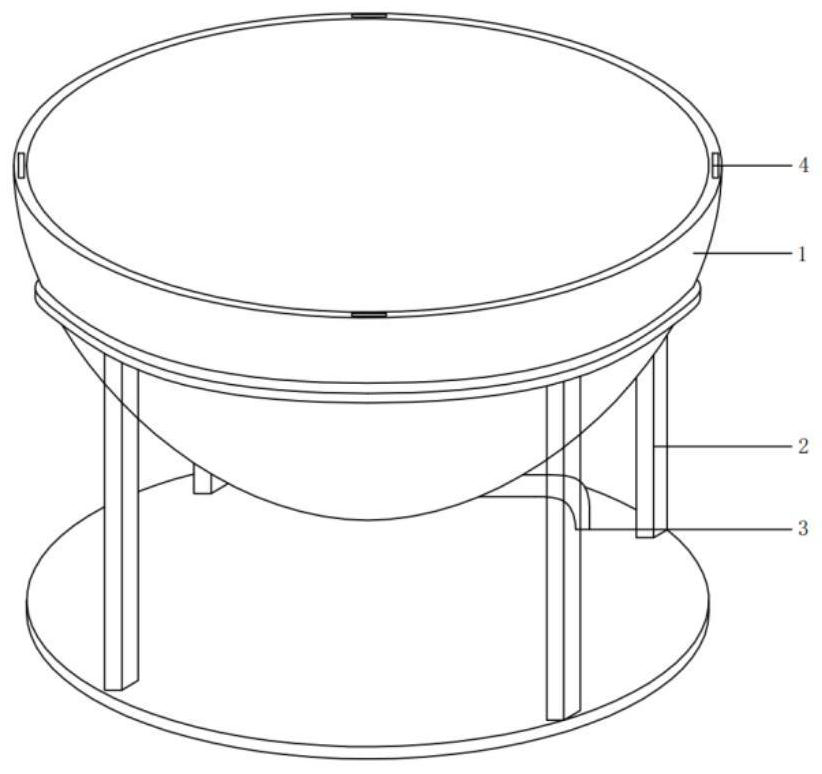

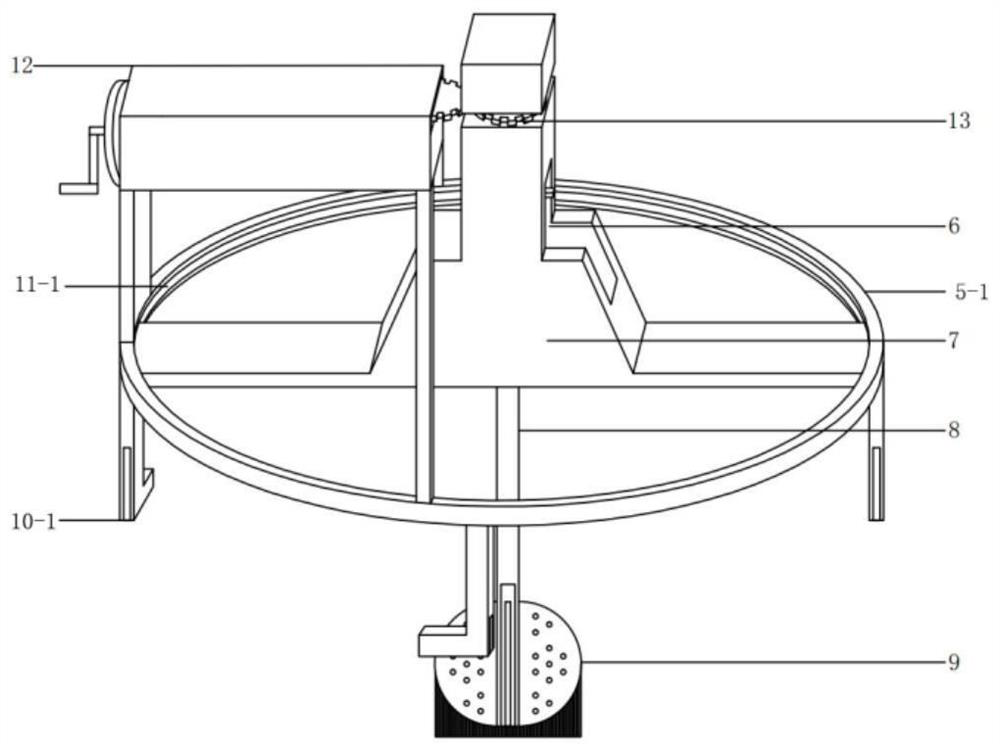

[0063] As shown in the figure, a laboratory foam concrete mixing device according to the present invention includes a spherical cap type cement mixing basin 1, a cement basin support 2, a slurry tap 3, a socket 4 for fixing the mixing component, a mixing component 1, Stirring component 2,

[0064] Wherein, the stirring assembly 1 includes a fixed seat ring-5-1, a stirring rod swing control system 6, a horizontal rotation system 17, a stirring rod 8, a controllable honeycomb stirring blade 9, a connection fixed plug-10-1, a rotating Race groove one 11-1, gear transmission case 12 and transmission gear 13;

[0065] The stirring assembly 2 includes a fixed seat ring 2 5-2, a connectin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com